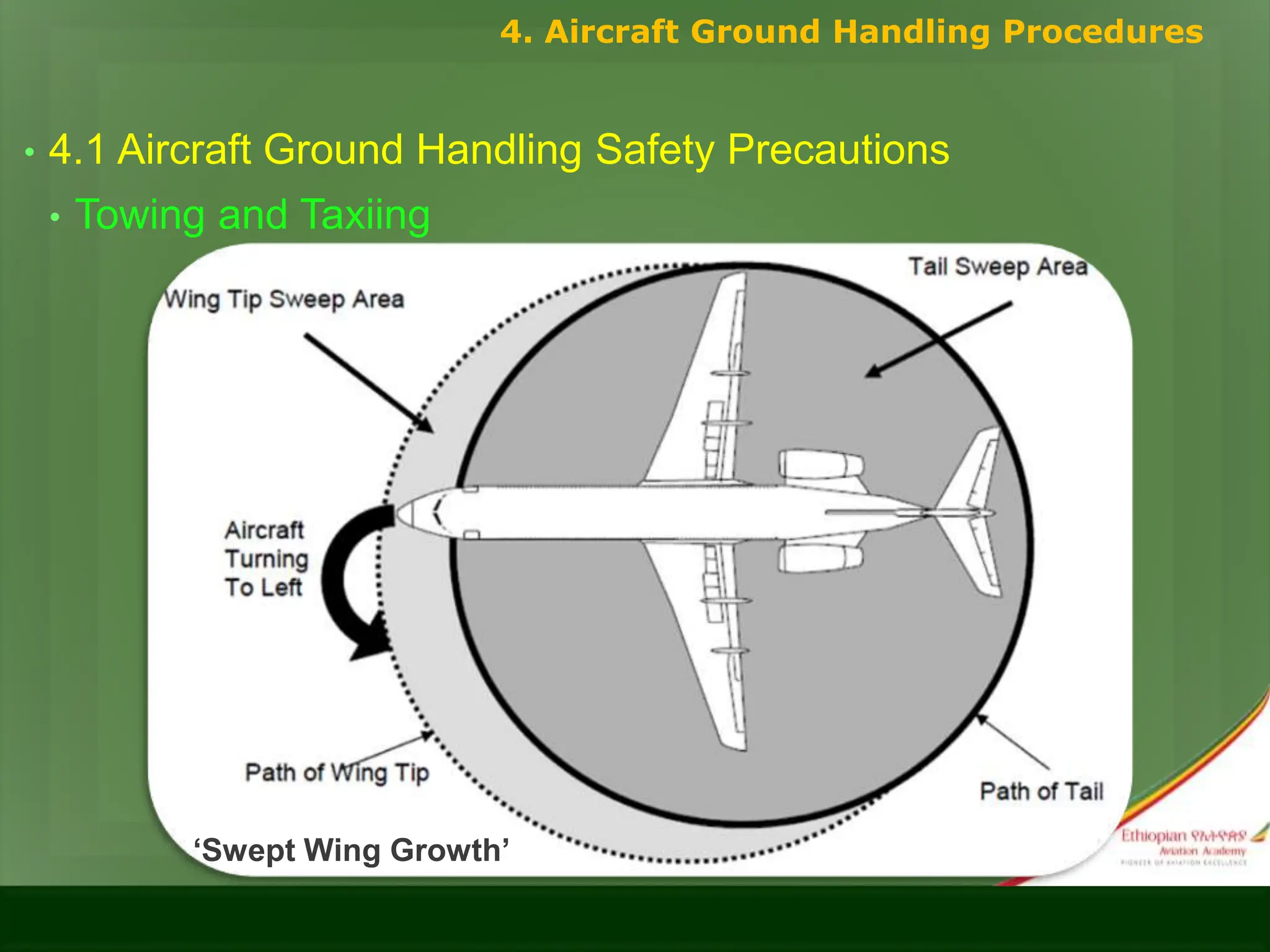

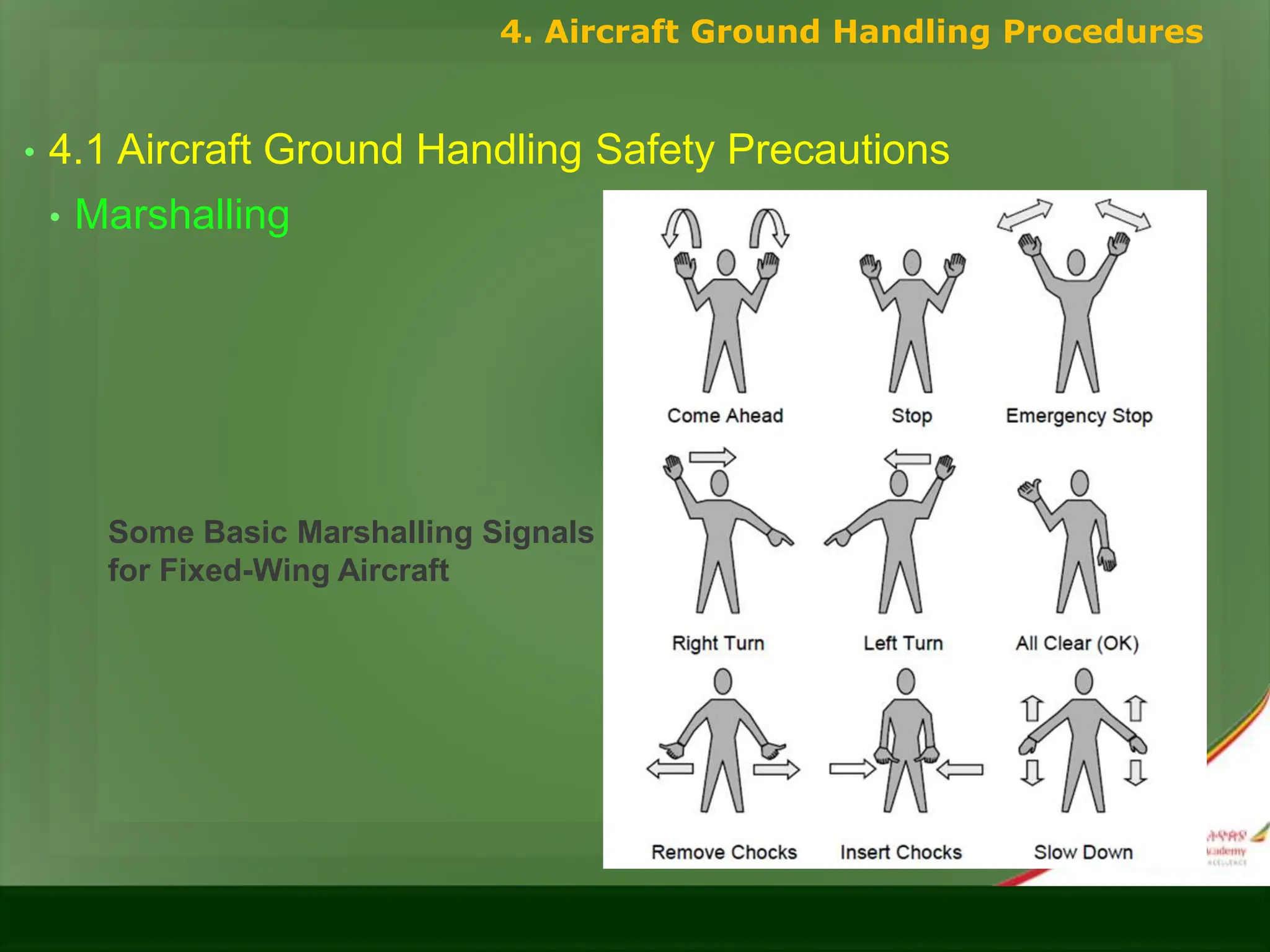

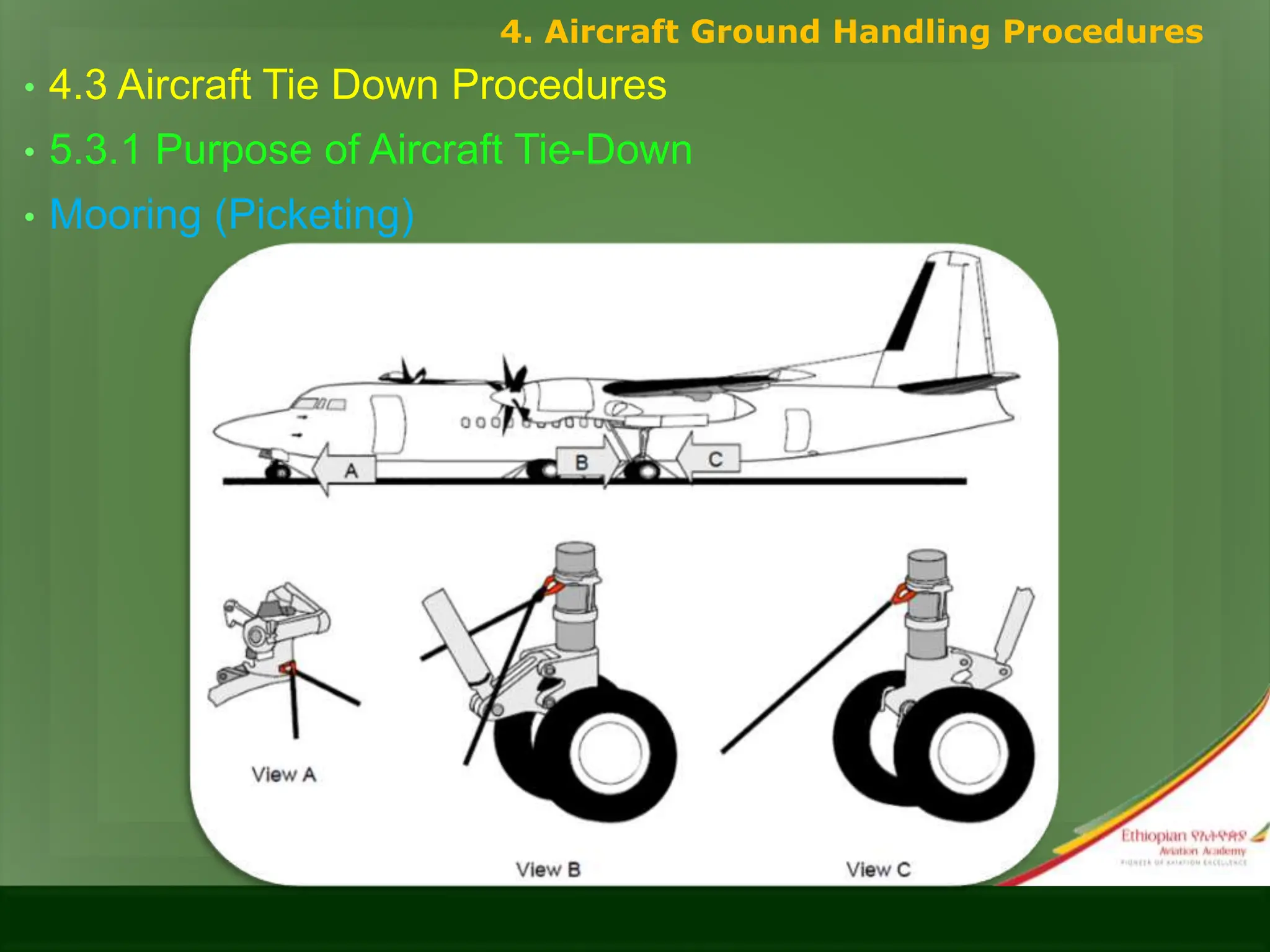

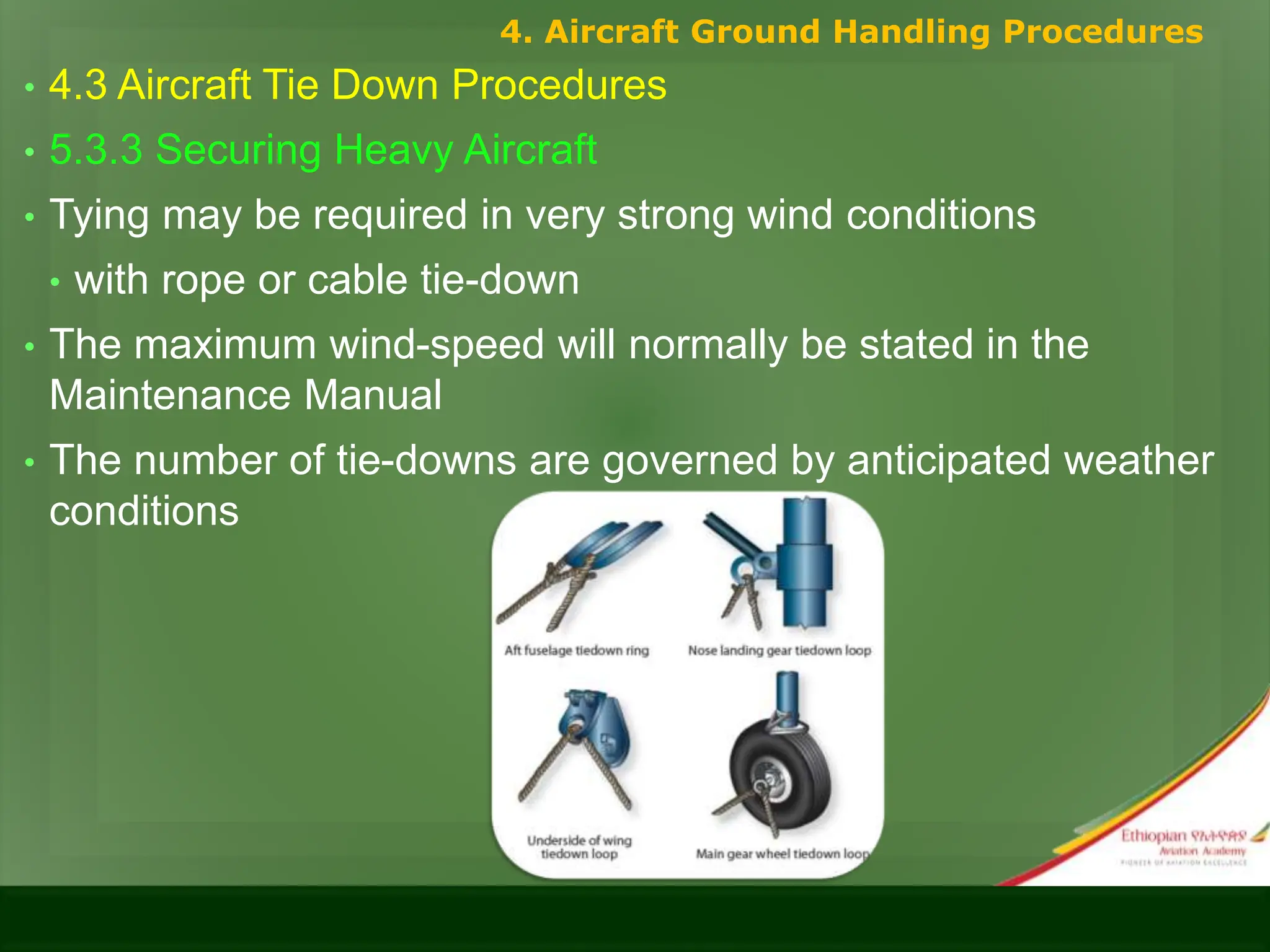

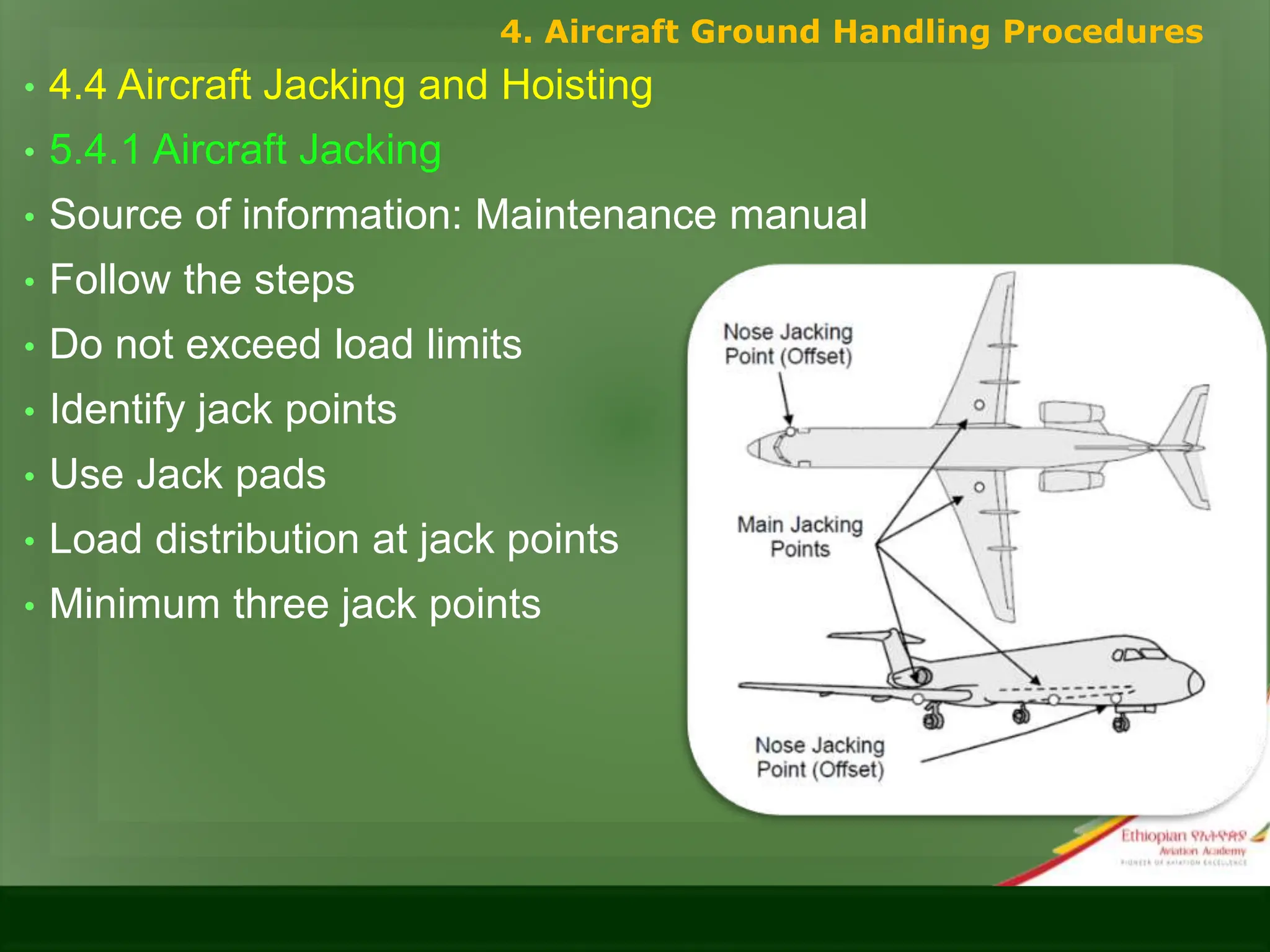

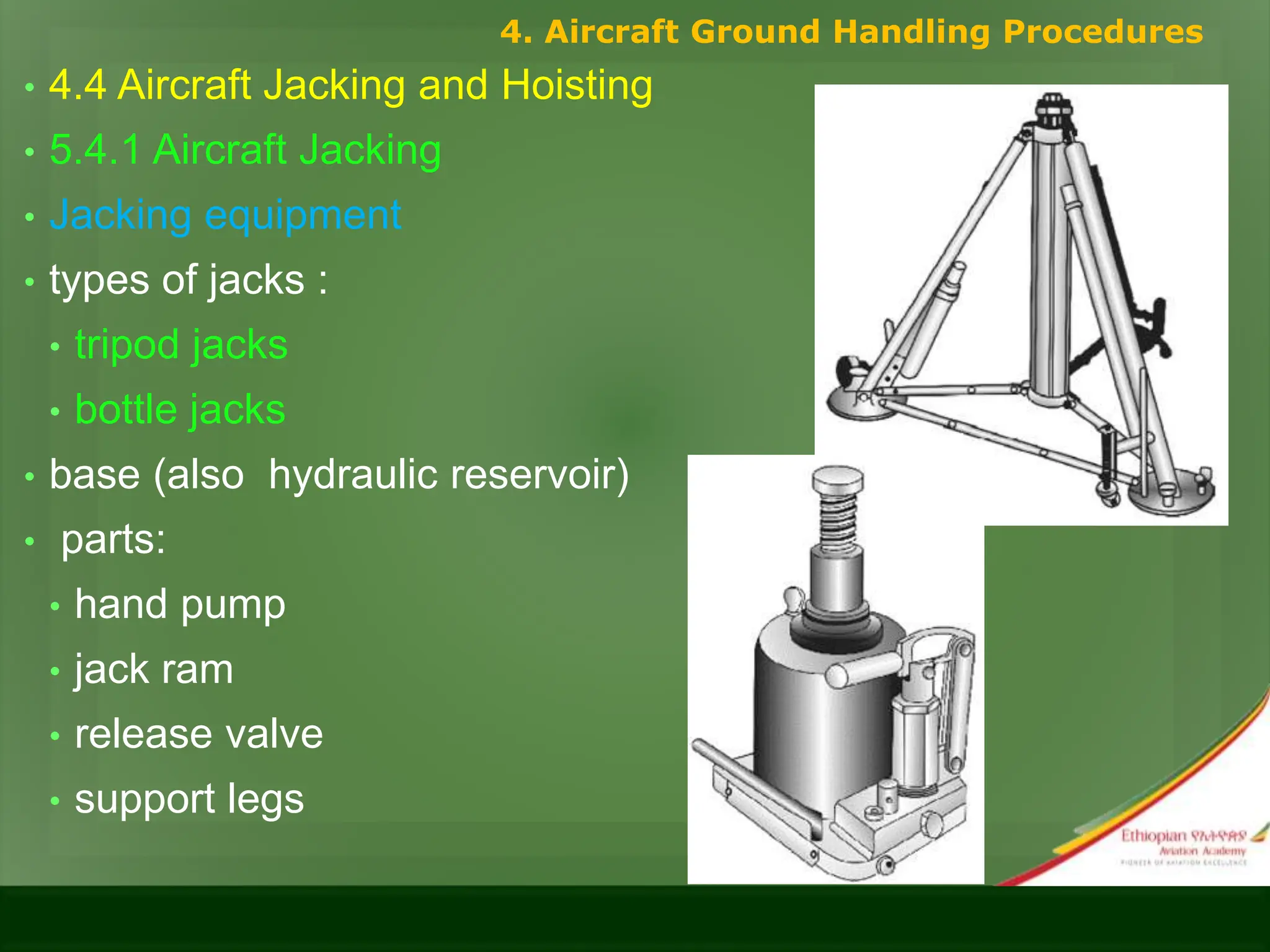

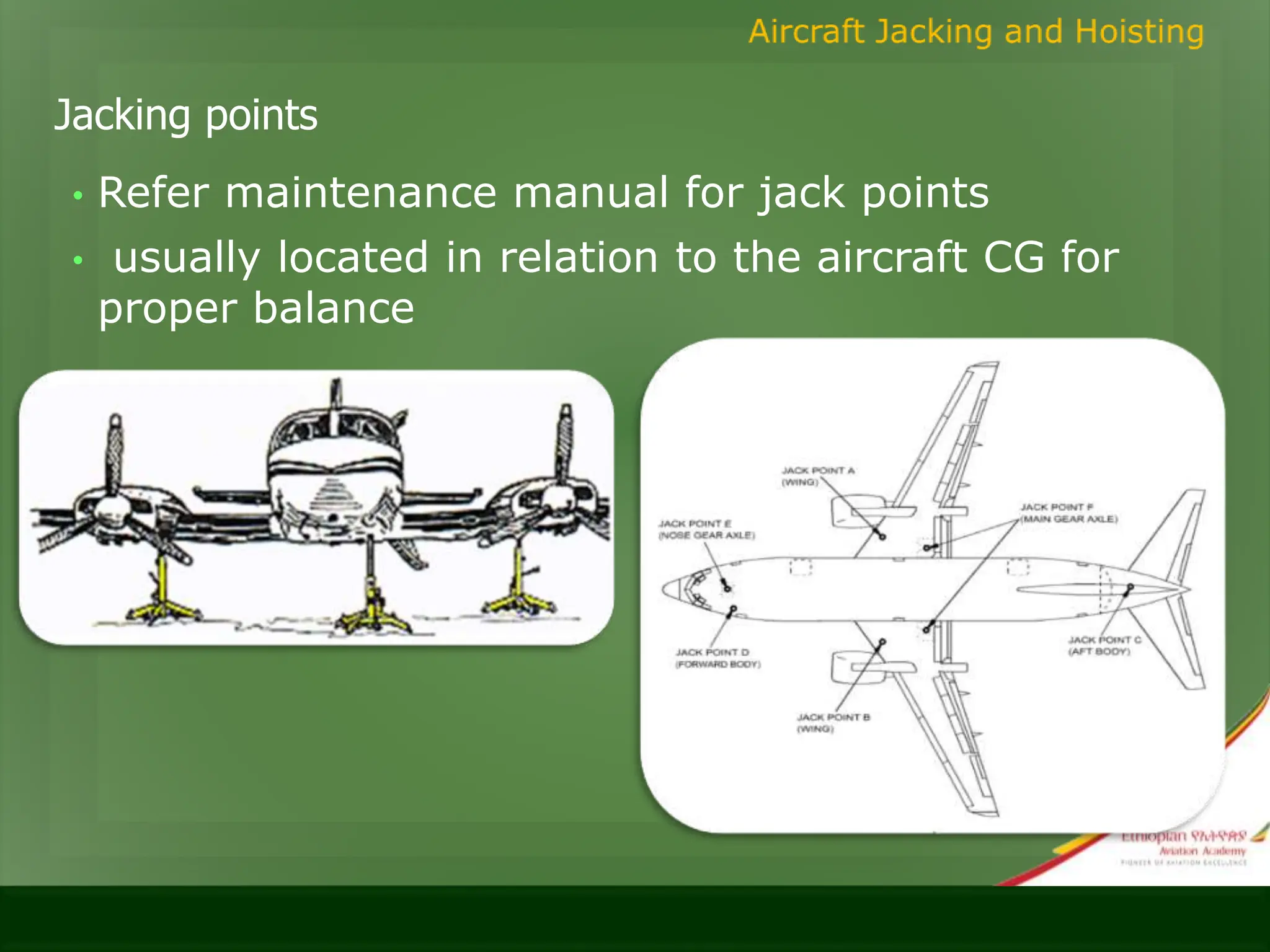

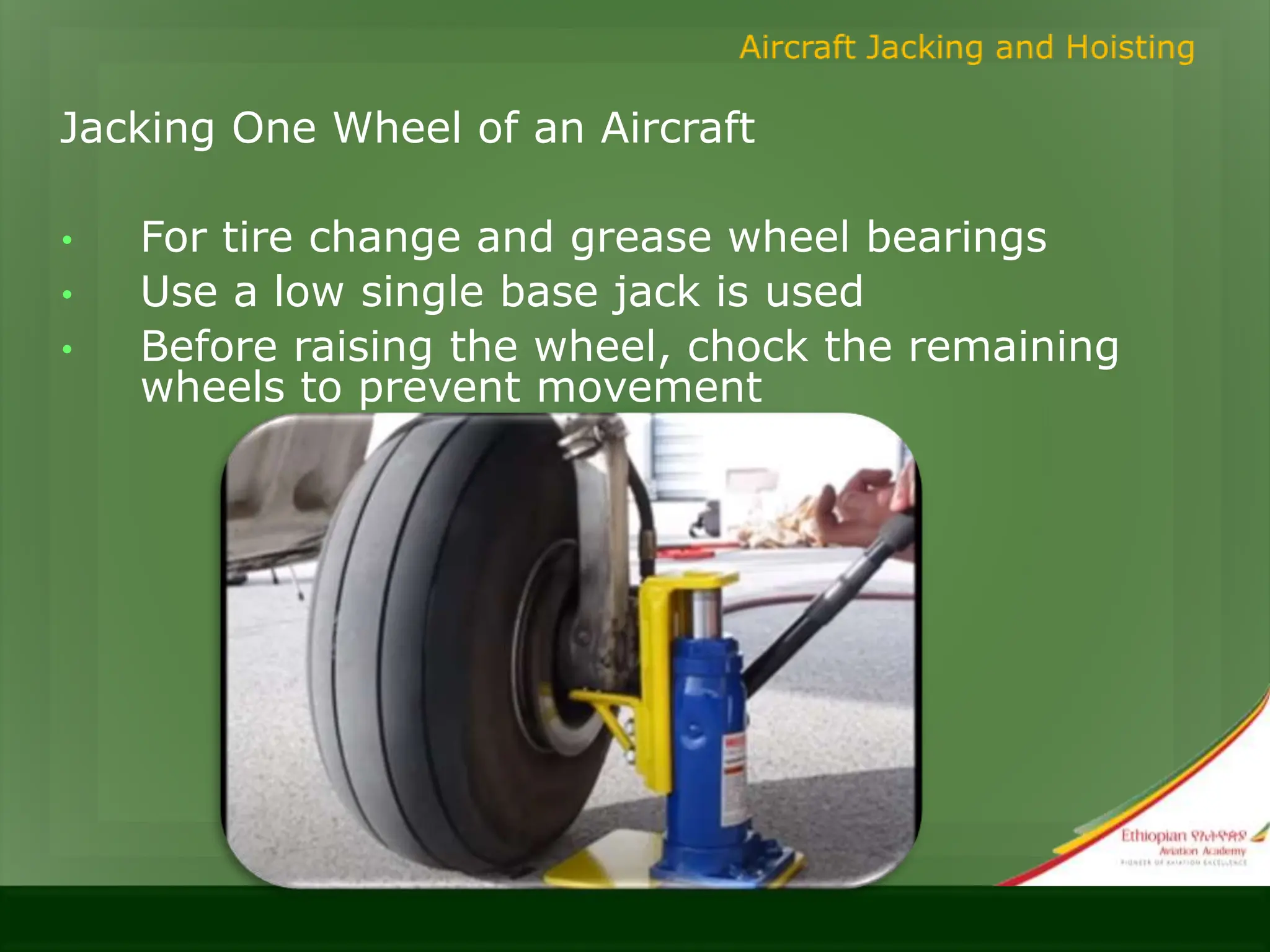

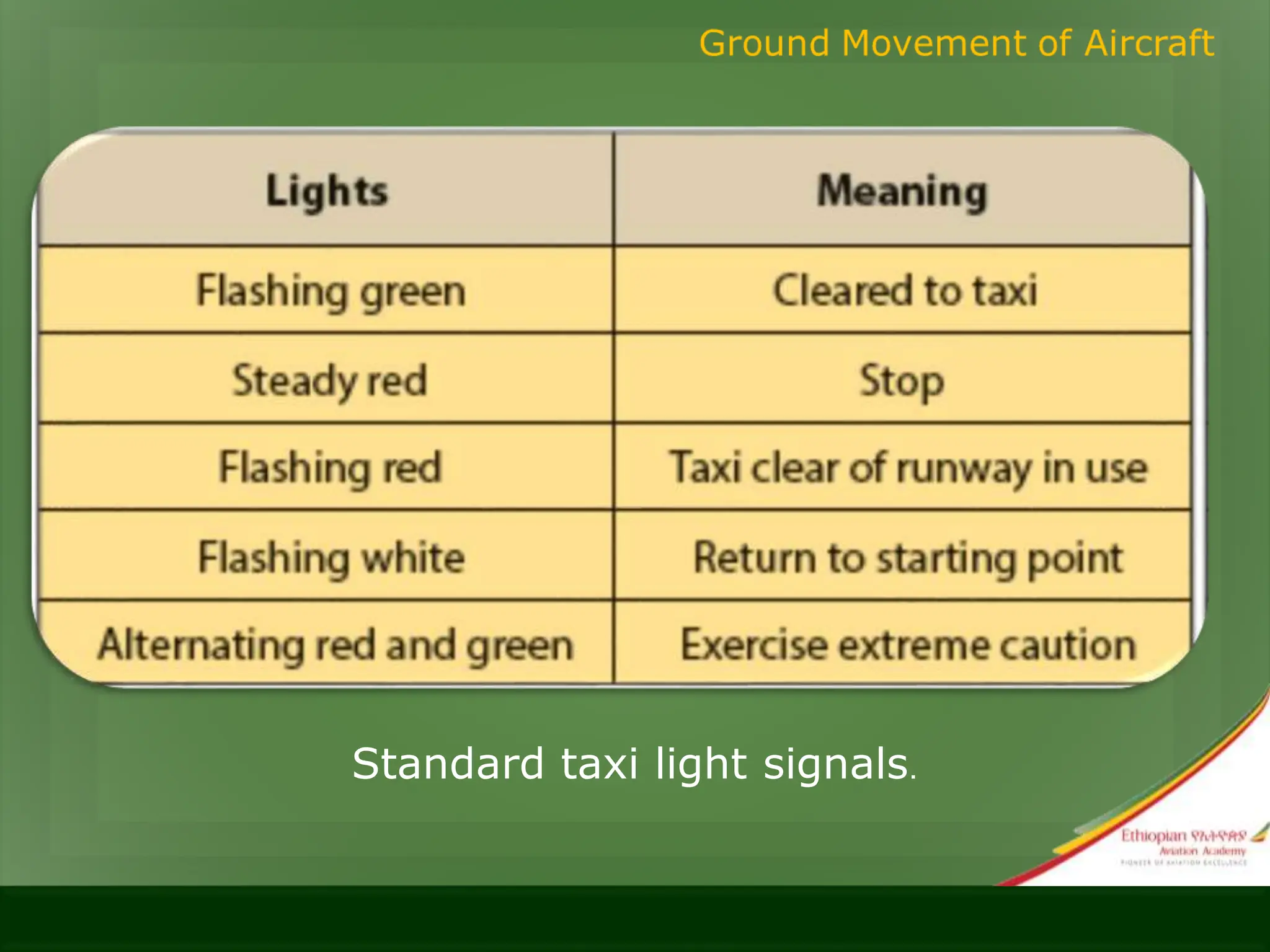

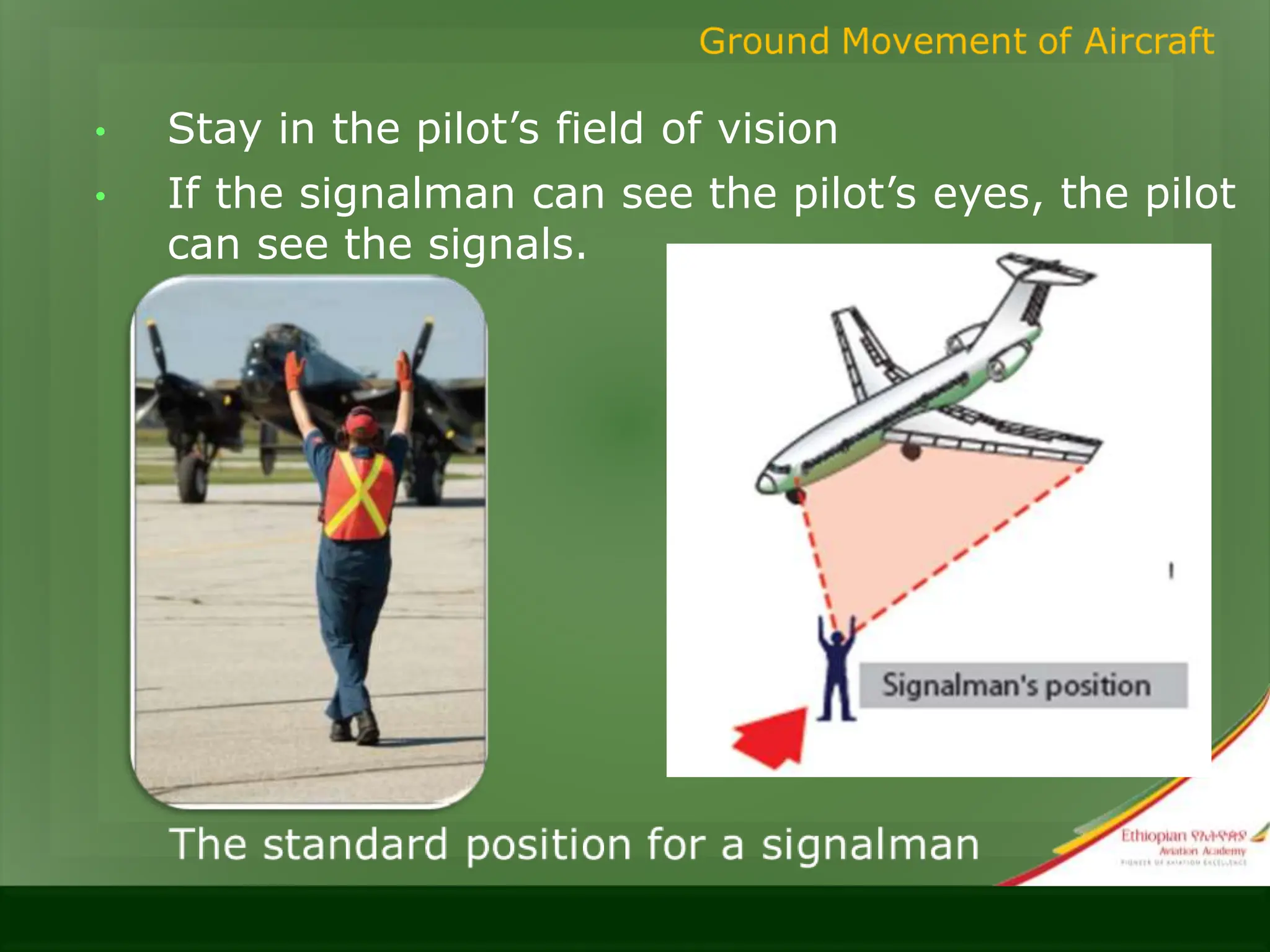

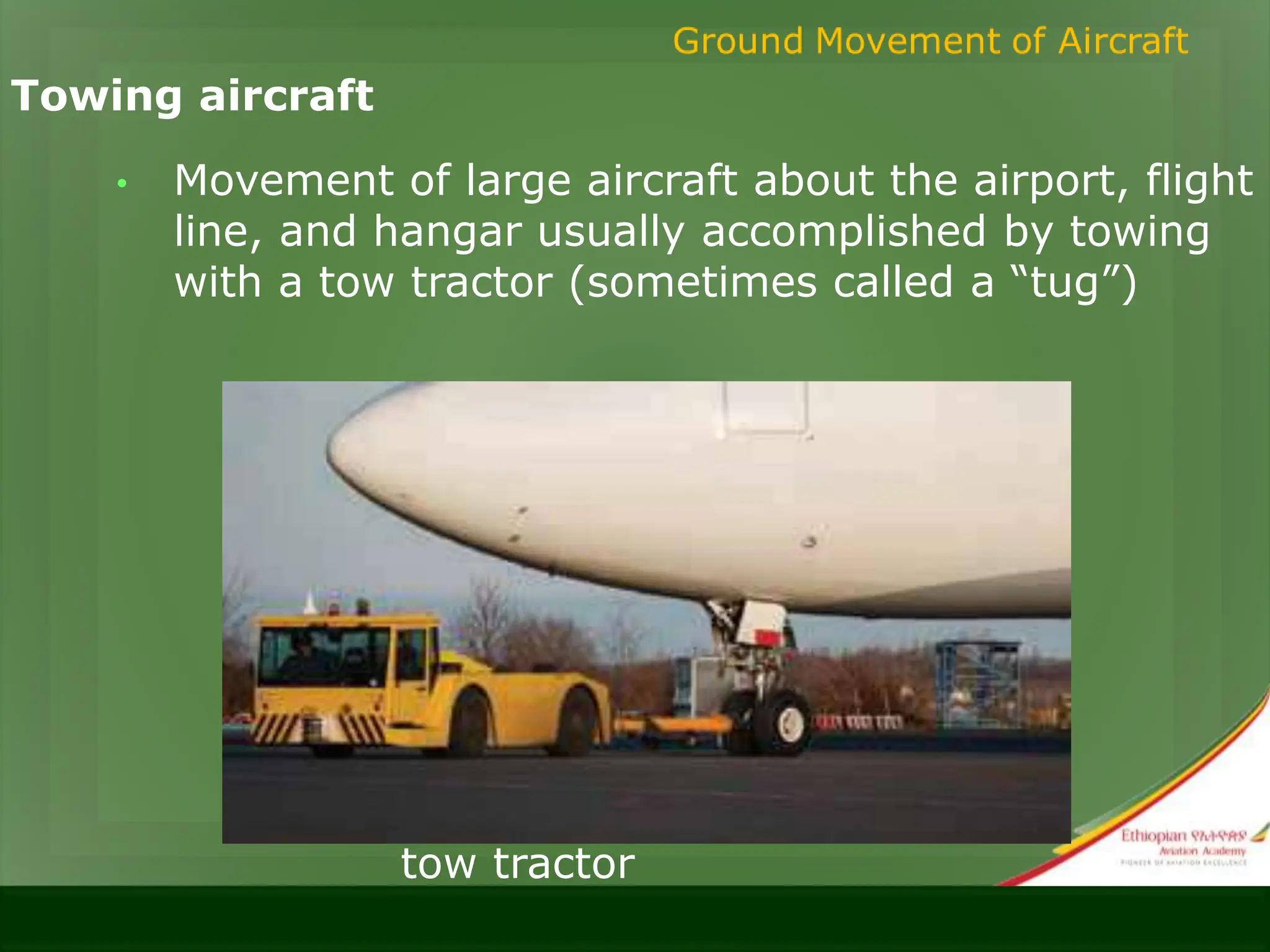

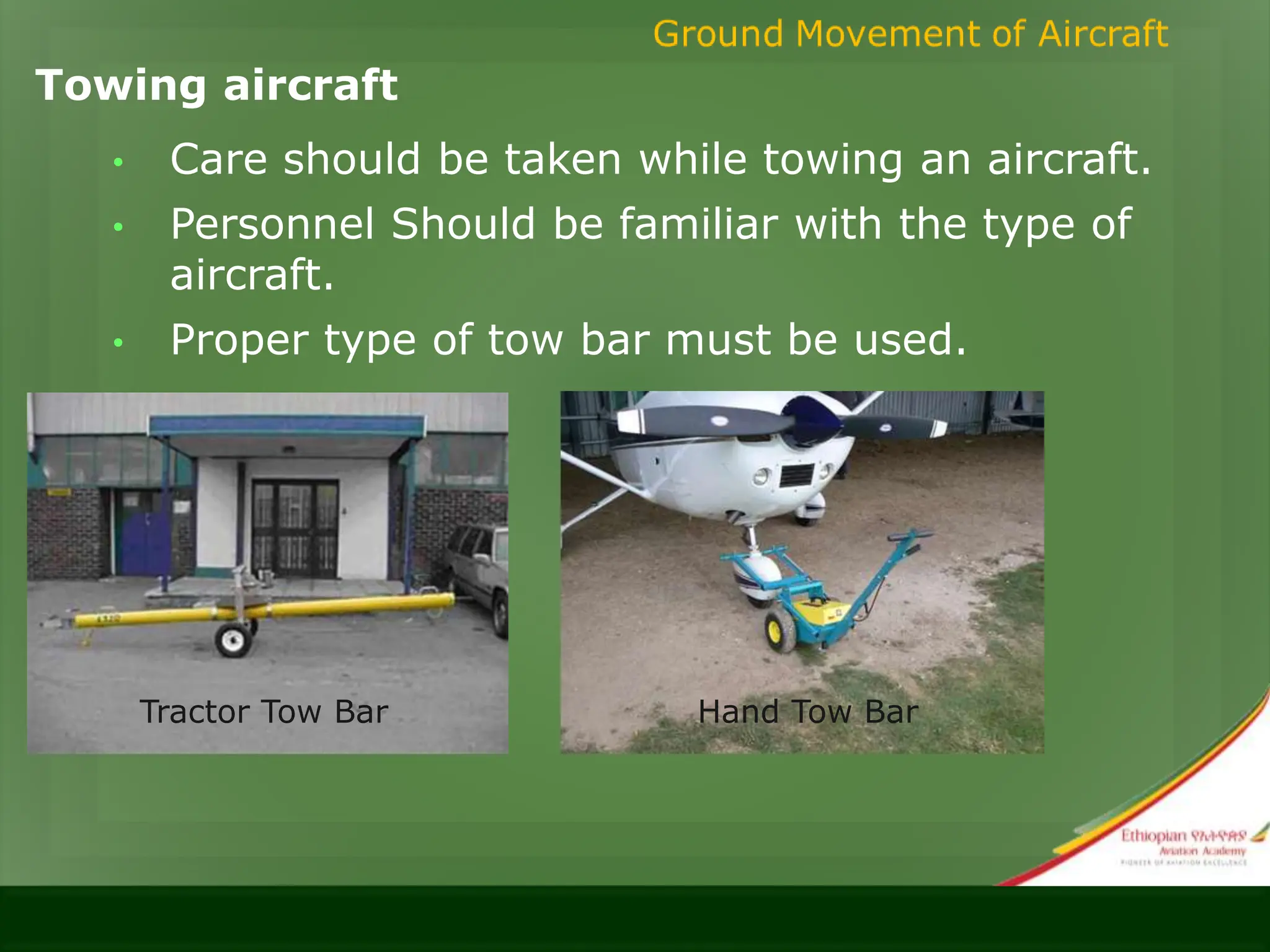

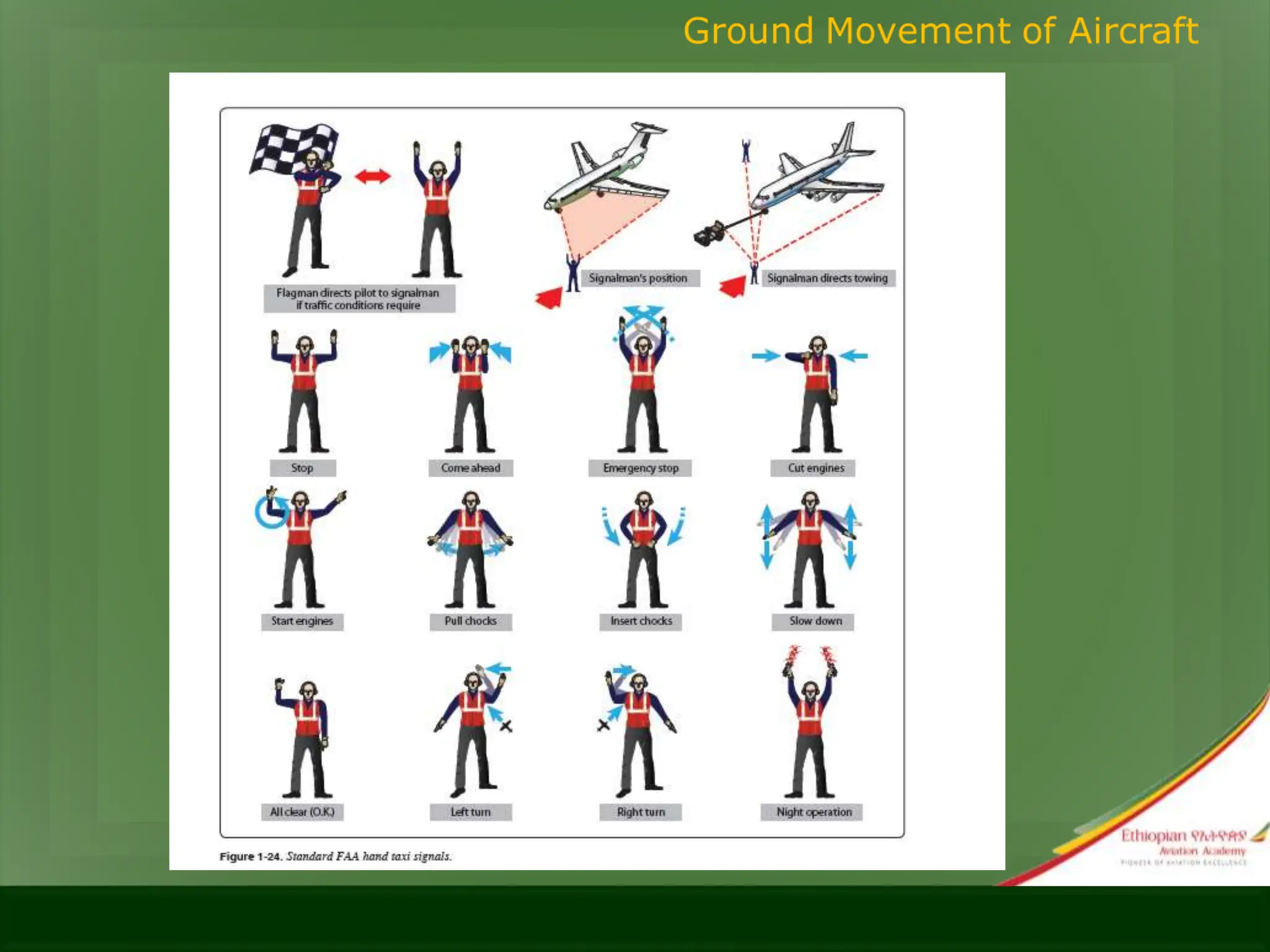

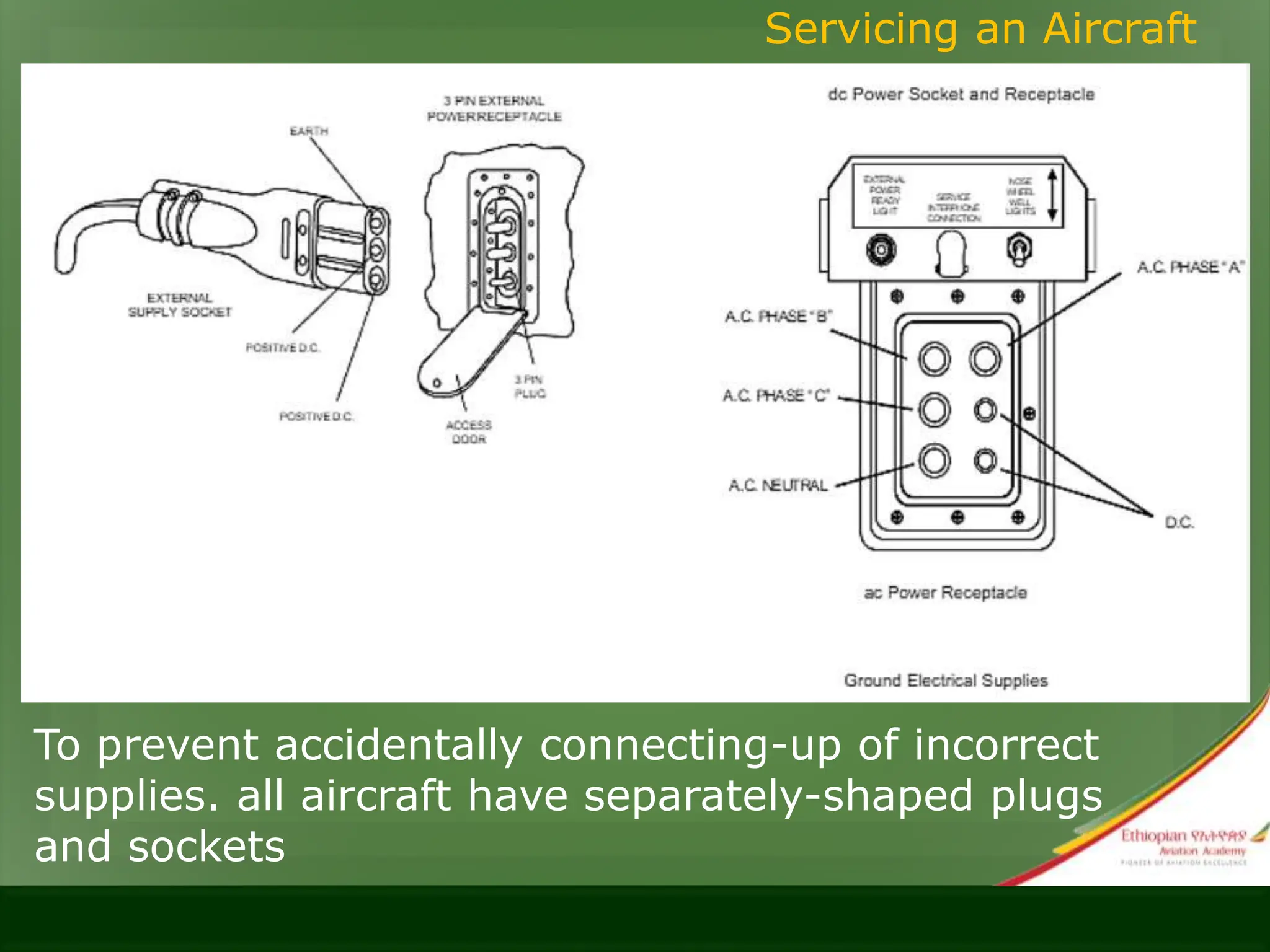

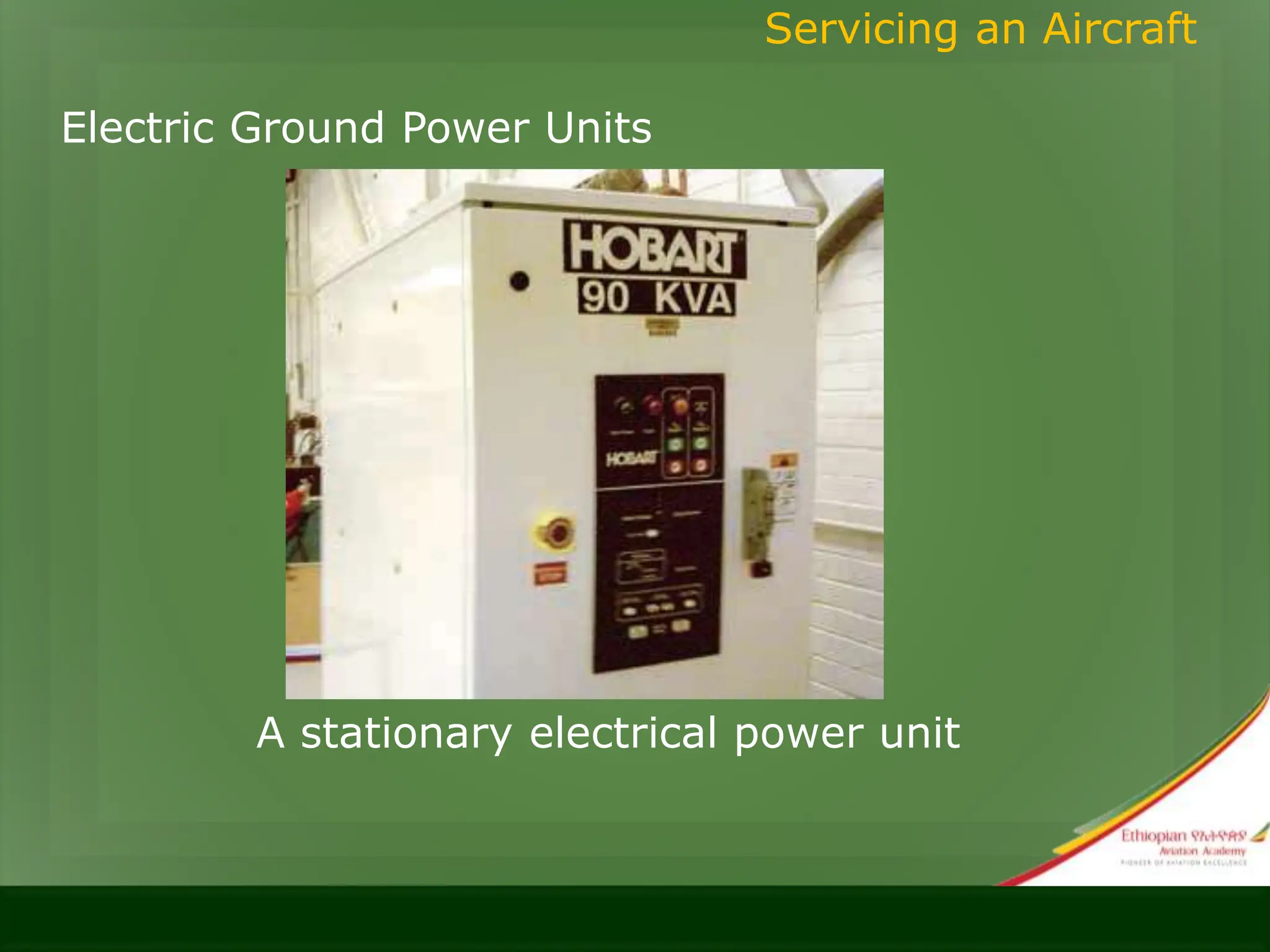

This document provides an overview of aircraft inspection, documentation, ground handling, and maintenance training. It discusses safety procedures for aircraft inspection, ground handling, towing, taxiing, parking, marshalling, fueling, jacking, and servicing. Precautions are outlined for propeller safety, towing and taxiing rules, control surface locking, tie-downs, jack points, and fuel identification. Ground support equipment for electrical and hydraulic power is also summarized. The goal is to train students on aircraft inspection and ground operations according to proper procedures.