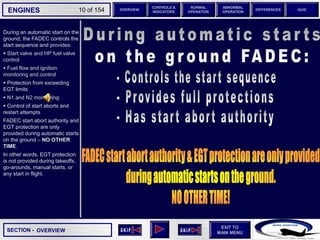

This document provides an overview of the engines on the Airbus A320 series aircraft. It describes the key components and systems, including the IAE V2500 high-bypass turbofan engines, Full Authority Digital Engine Control (FADEC), fuel system, and ignition system. It explains that the FADEC controls and monitors engine operation using EPR or N1 modes. It also discusses engine starts, idle settings, and protections provided during automatic starts on the ground.

![SECTION -

EXIT TO

MAIN MENU

ENGINES OVERVIEW

NORMAL

OPERATION

ABNORMAL

OPERATION

CONTROLS &

INDICATORS

DIFFERENCES QUIZ

74 of 154

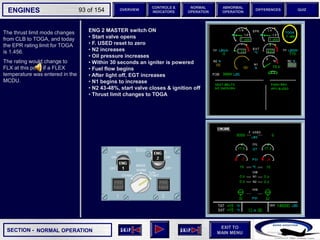

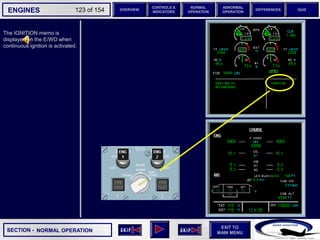

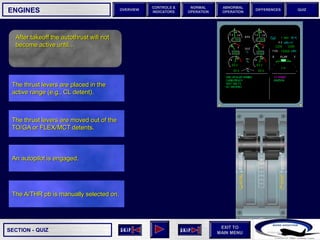

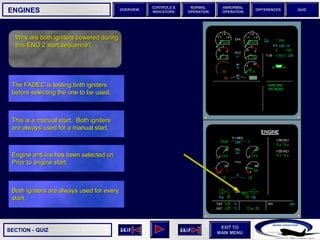

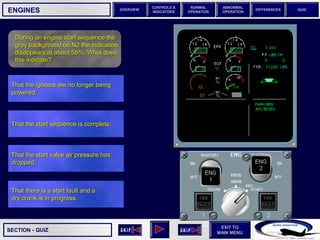

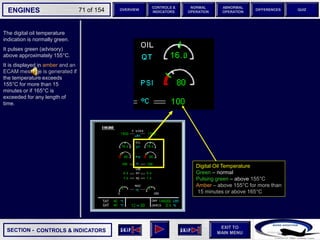

Start Valve

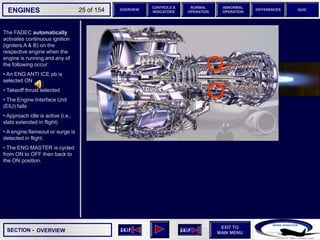

During engine start, the nacelle

temperature indications are

replaced by information

relating to ignition and start

valve operation.

The FADEC selected igniters

(A, B, or both [A &B] ) are

displayed when selected for

use.

The letter indicates that the

specific igniter, or igniters,

have been activated. It DOES

NOT indicate if they are

actually firing.

Start valve indications are

displayed below the igniters.

The start valves are displayed

either open or closed.

Below each start valve is a

digital indication of the bleed

pressure available to that start

valve.

The bleed pressure indication

is displayed in amber if the

minimum or maximum limits

are exceeded.

Valve Open

Valve Closed

CONTROLS & INDICATORS

FADEC selected igniter - indicates igniter is activated, NOT that the igniter is firing

Bleed Pressure

Green – normal

Amber – min or max pressure is exceeded](https://image.slidesharecdn.com/engines-230712094839-5fd7f2a0/85/Engines-ppt-74-320.jpg)