The document summarizes several key ERP modules:

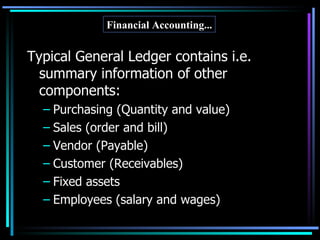

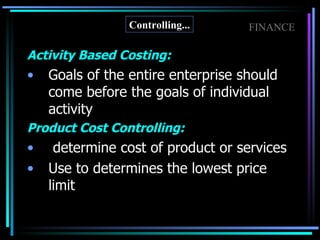

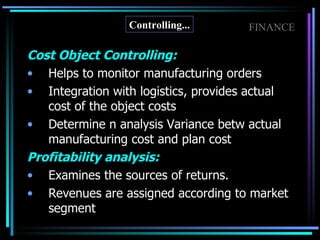

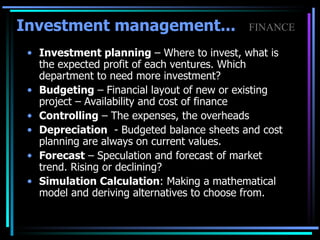

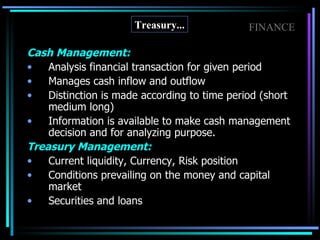

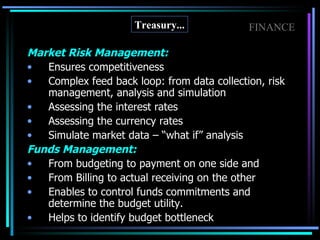

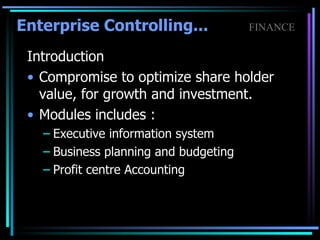

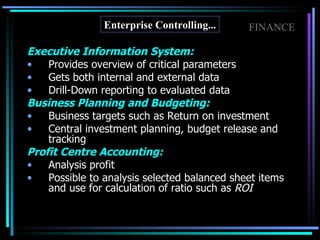

1) The finance module handles accounting, cost management, investment planning and treasury management. It includes sub-modules like general ledger, accounts receivable/payable, and asset accounting.

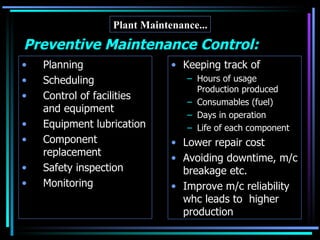

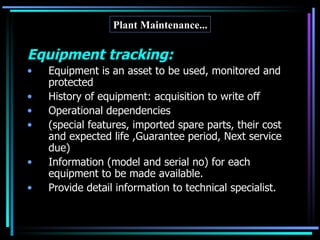

2) The plant maintenance module manages equipment maintenance and tracking through preventative maintenance, component tracking, and warranty claims.

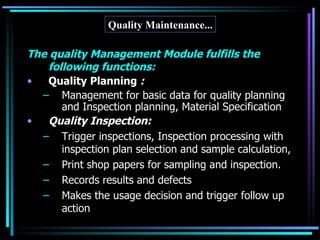

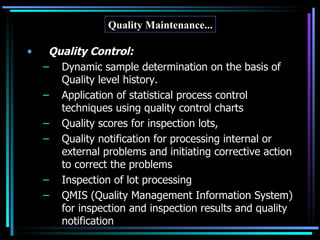

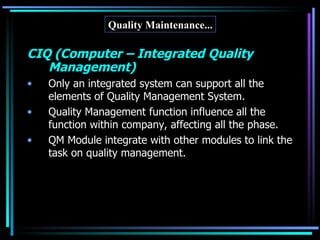

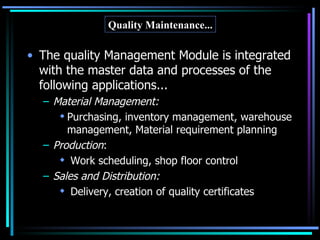

3) The quality management module supports quality planning, inspection, and control through tools like CAQ, CIQ, and statistical process control.

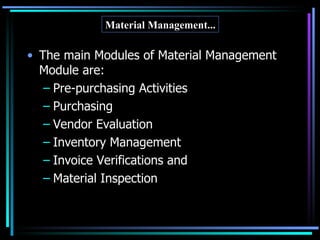

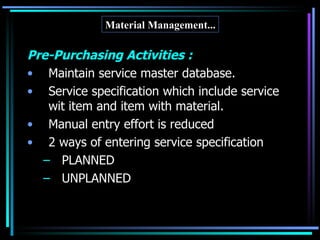

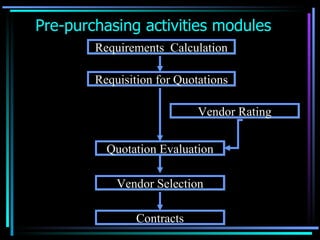

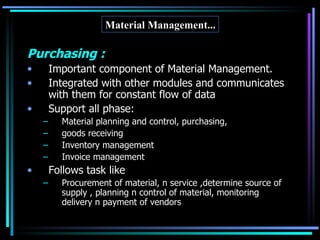

4) The materials management module handles pre-purchasing, purchasing, vendor evaluation, inventory management, and invoice verification to optimize the procurement process.