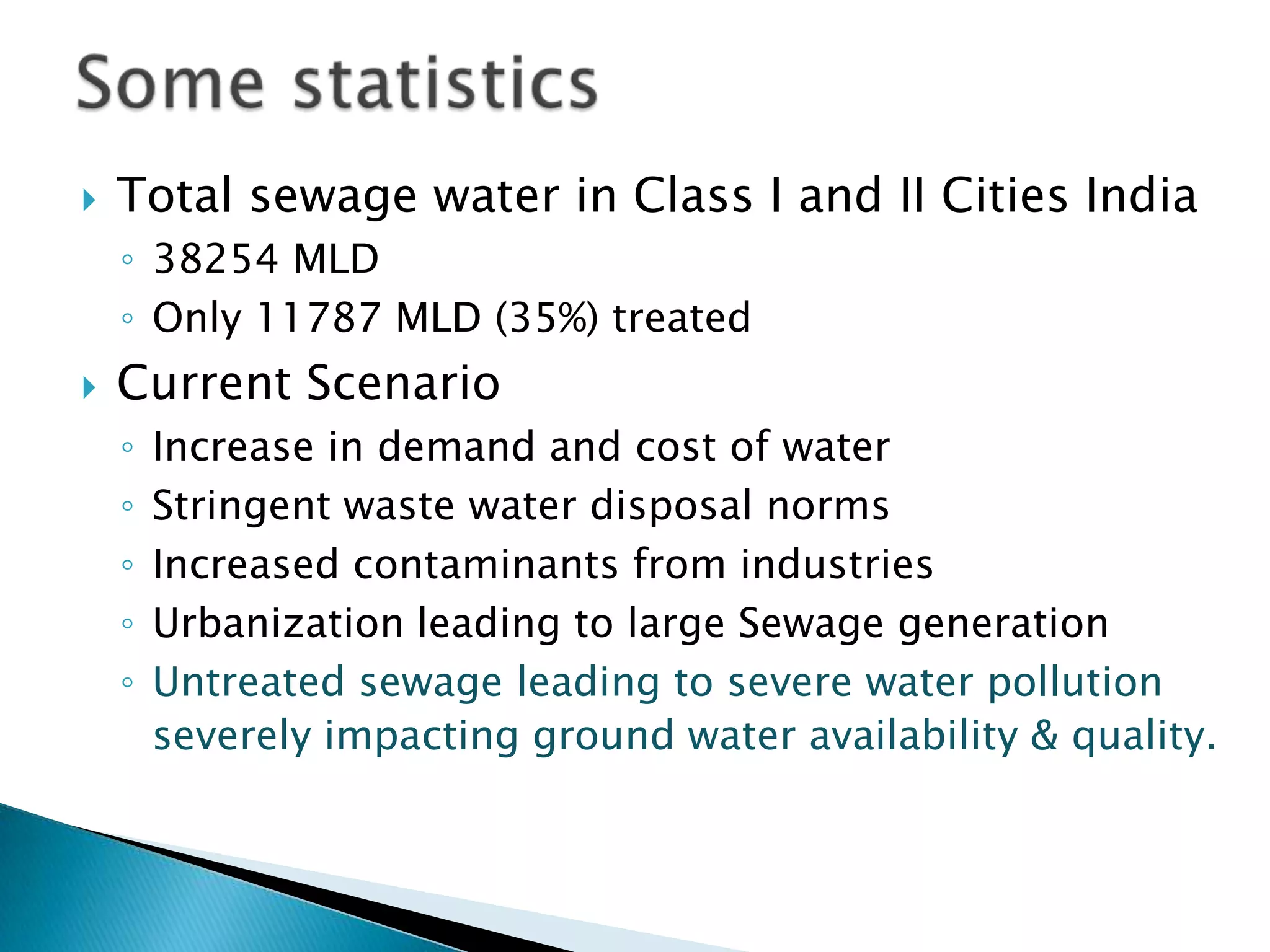

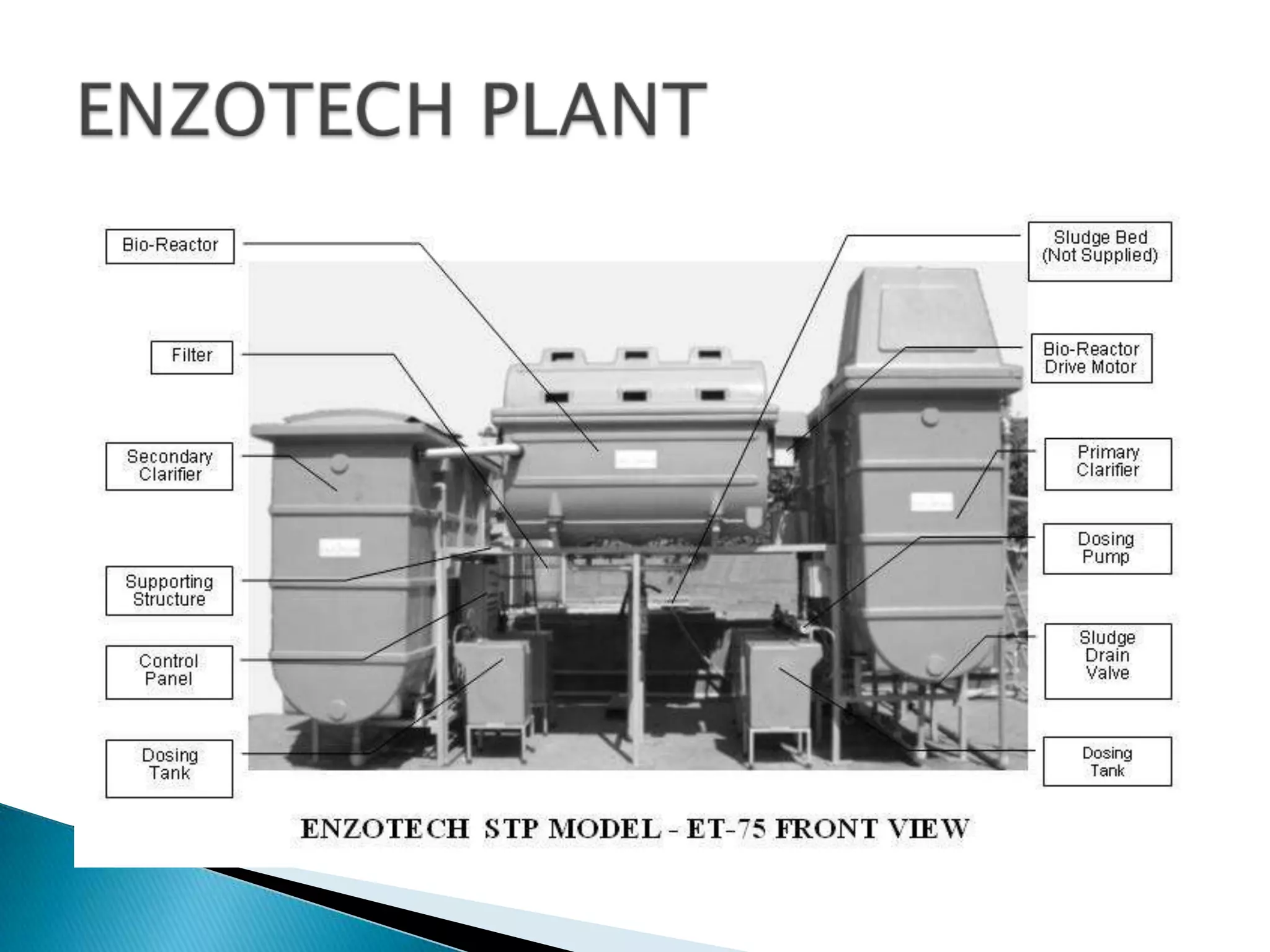

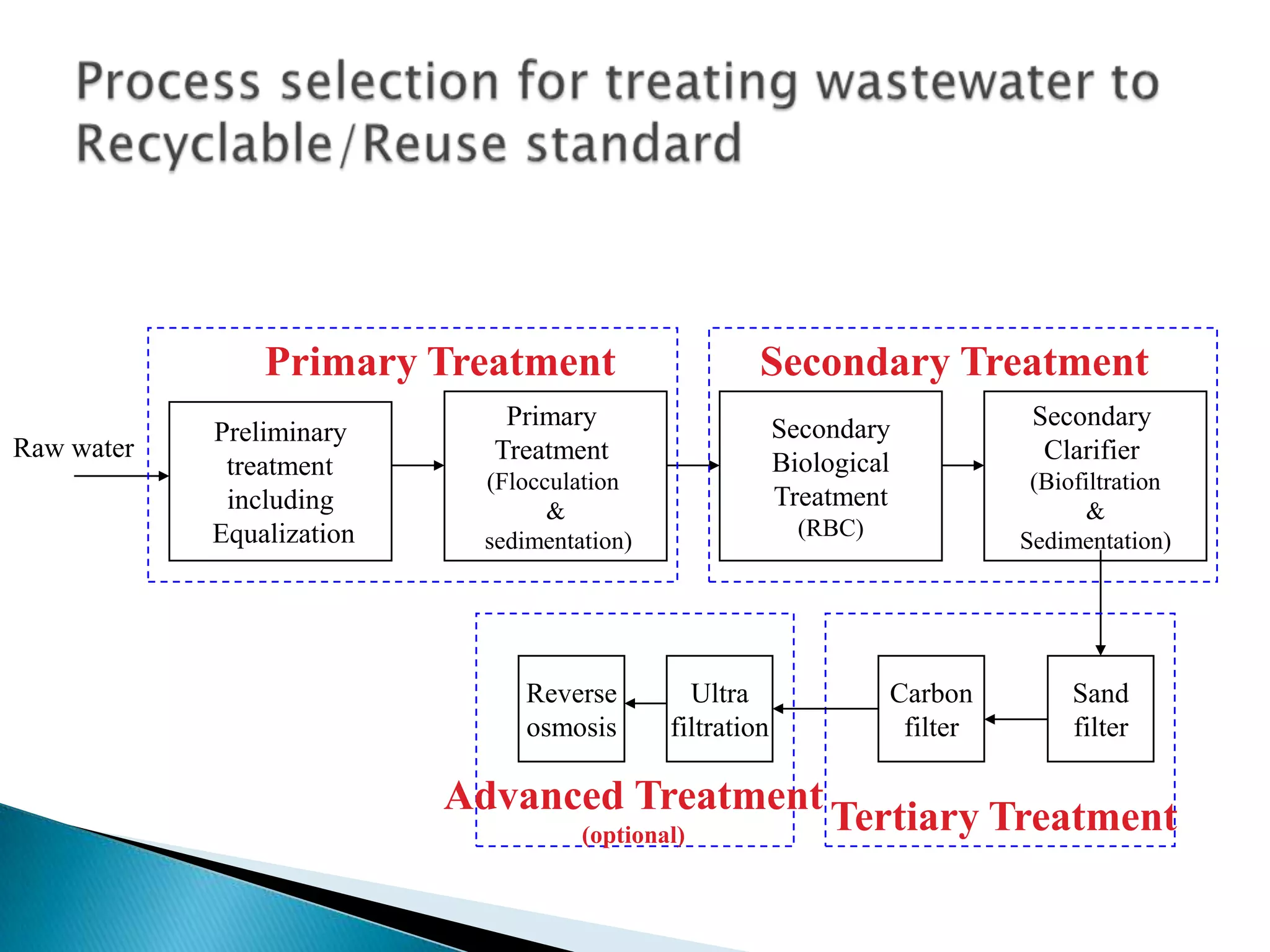

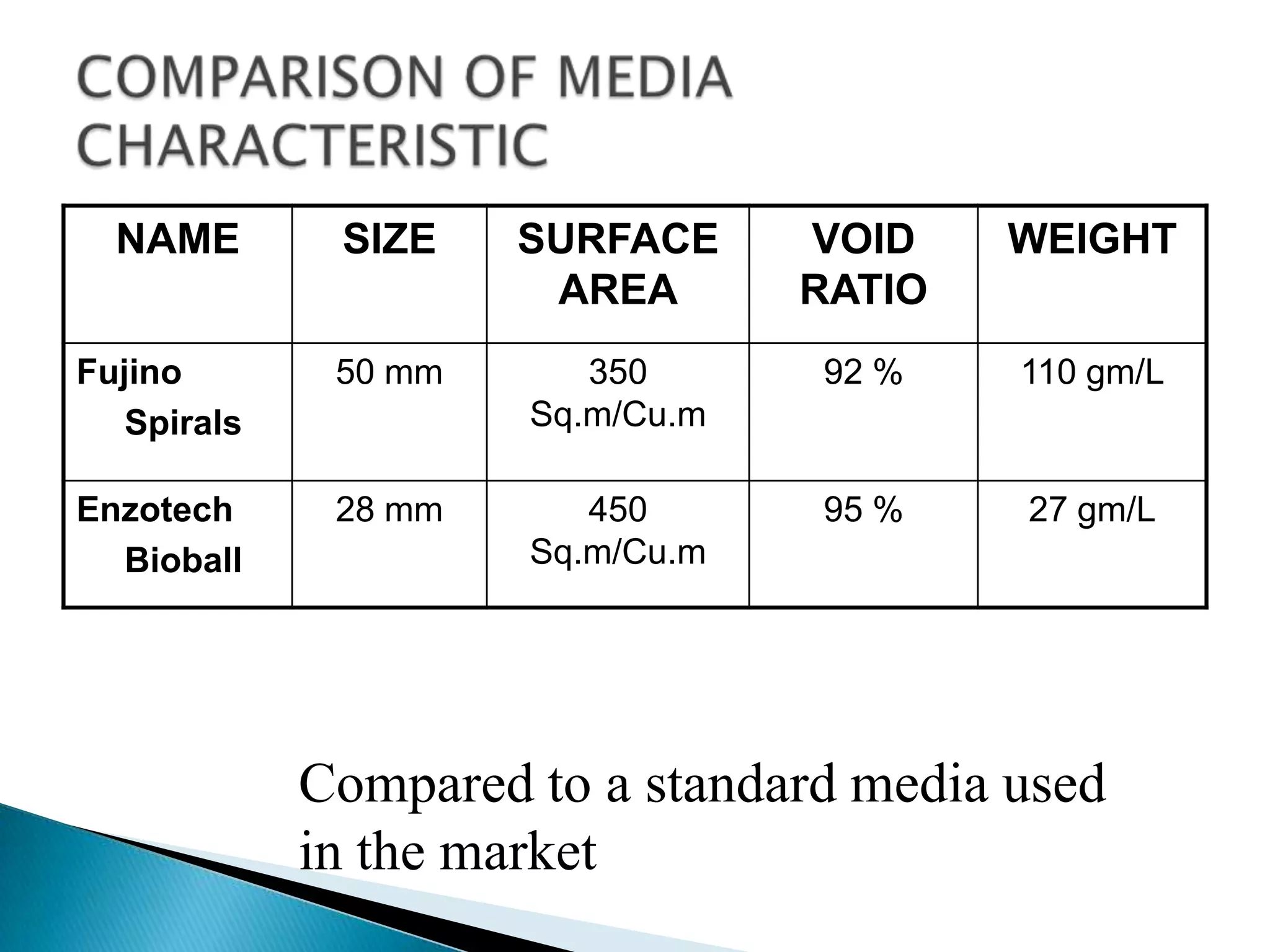

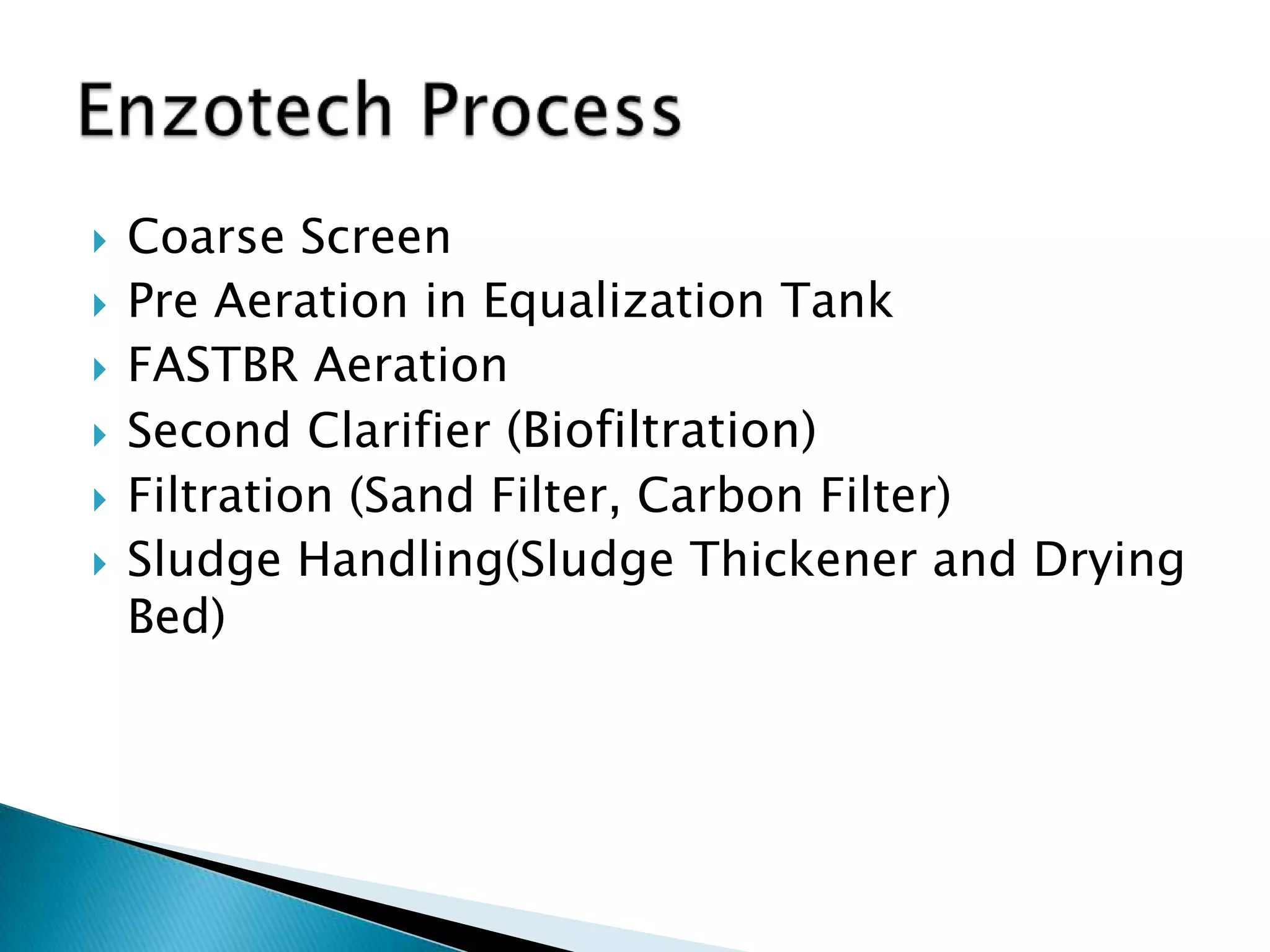

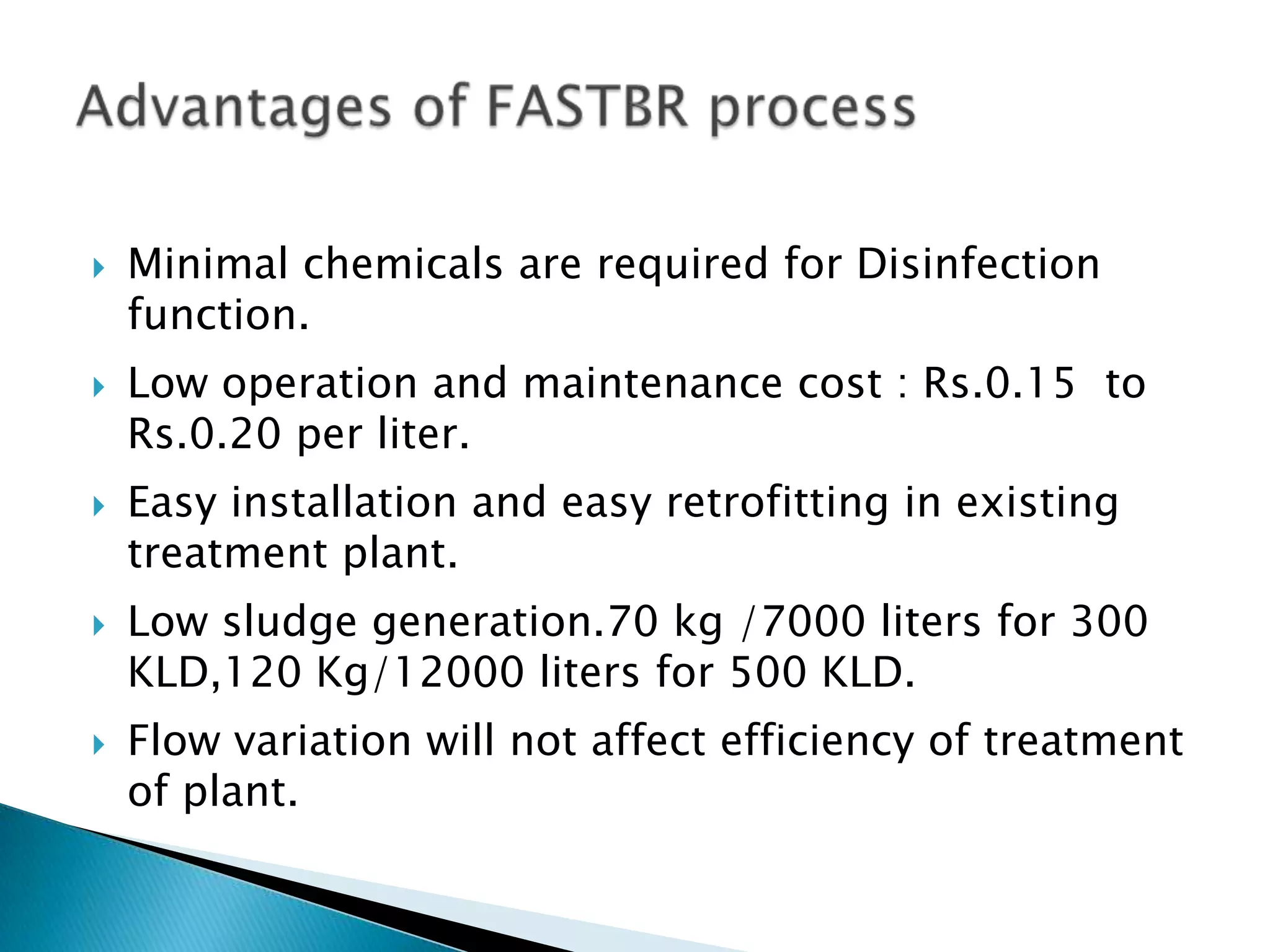

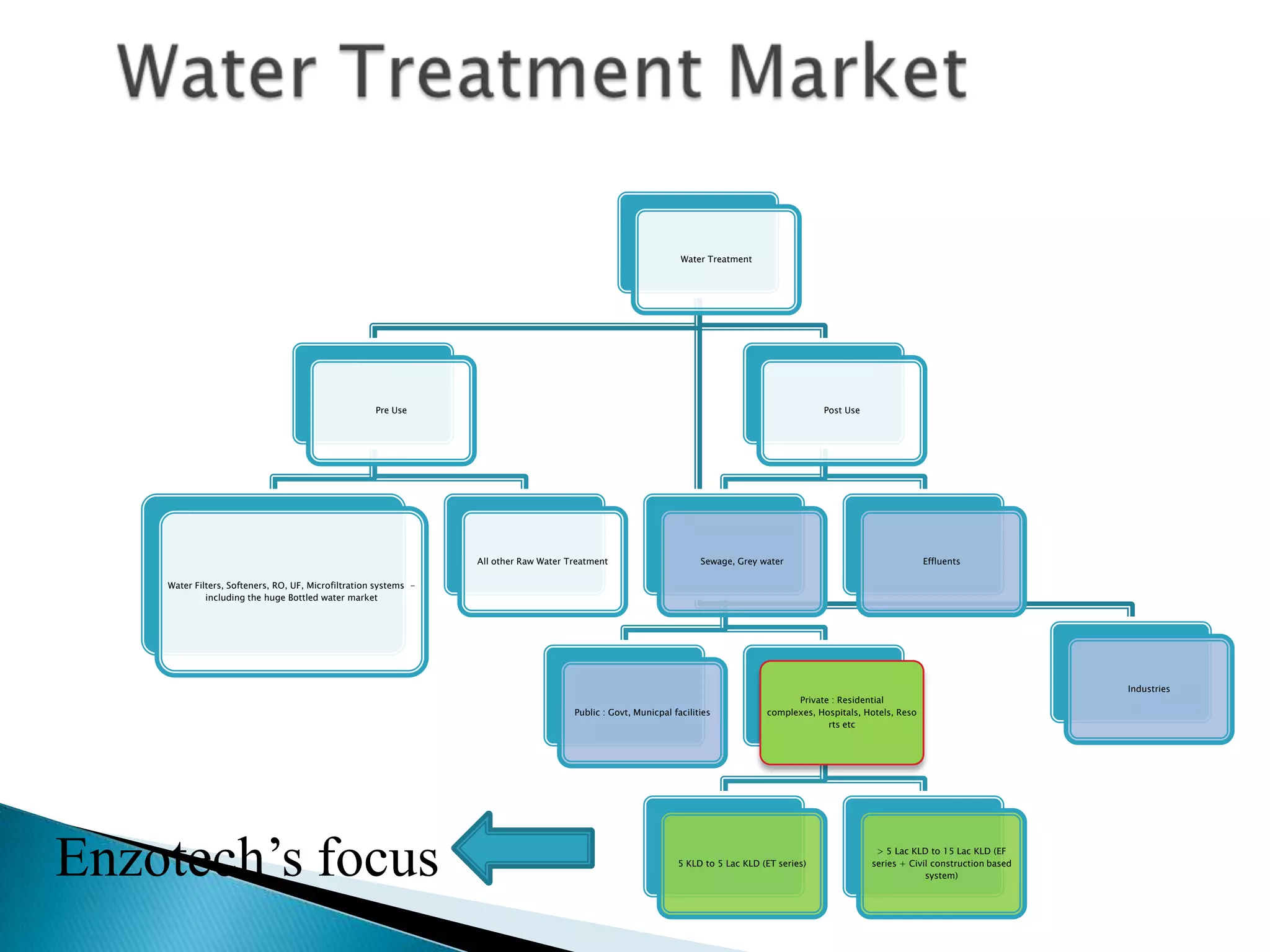

This document discusses water treatment and recycling solutions to address India's growing water needs. It notes that only 35% of sewage water in major Indian cities is currently treated. It then provides details on Enzotech's patented bio-tech water treatment process and packaged plants. Their process uses specialized bacteria and enzymes to effectively treat sewage with minimal sludge generation and power consumption. Enzotech has over 125 installations across India and Africa treating water volumes from 10 KLD to 450 KLD.