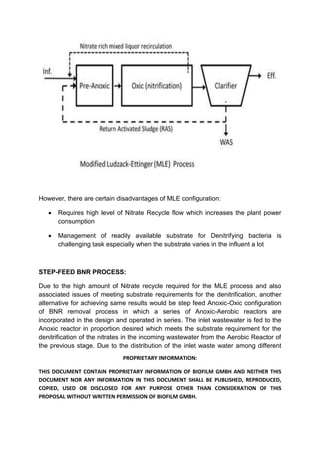

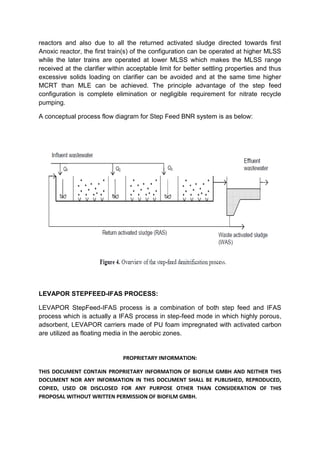

The document contains proprietary information about Levapor's StepFeed-IFAS wastewater treatment process. It describes how the process combines step feed activated sludge with integrated fixed film activated sludge using Levapor's porous carriers to achieve higher nutrient removal with a smaller footprint. The carriers' properties allow for stable biological treatment, faster start-up, and better ability to handle toxic loads compared to other carrier materials.