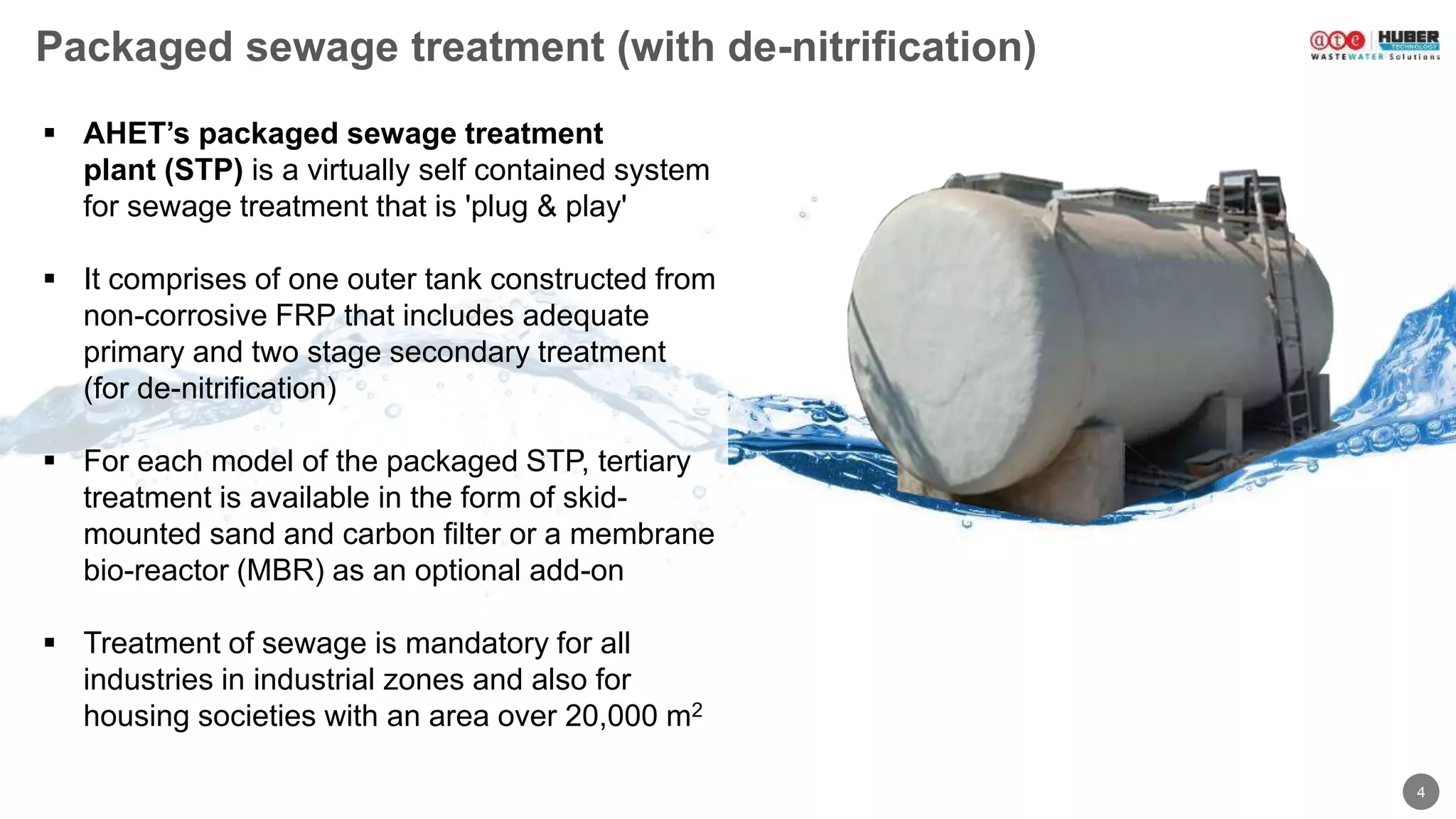

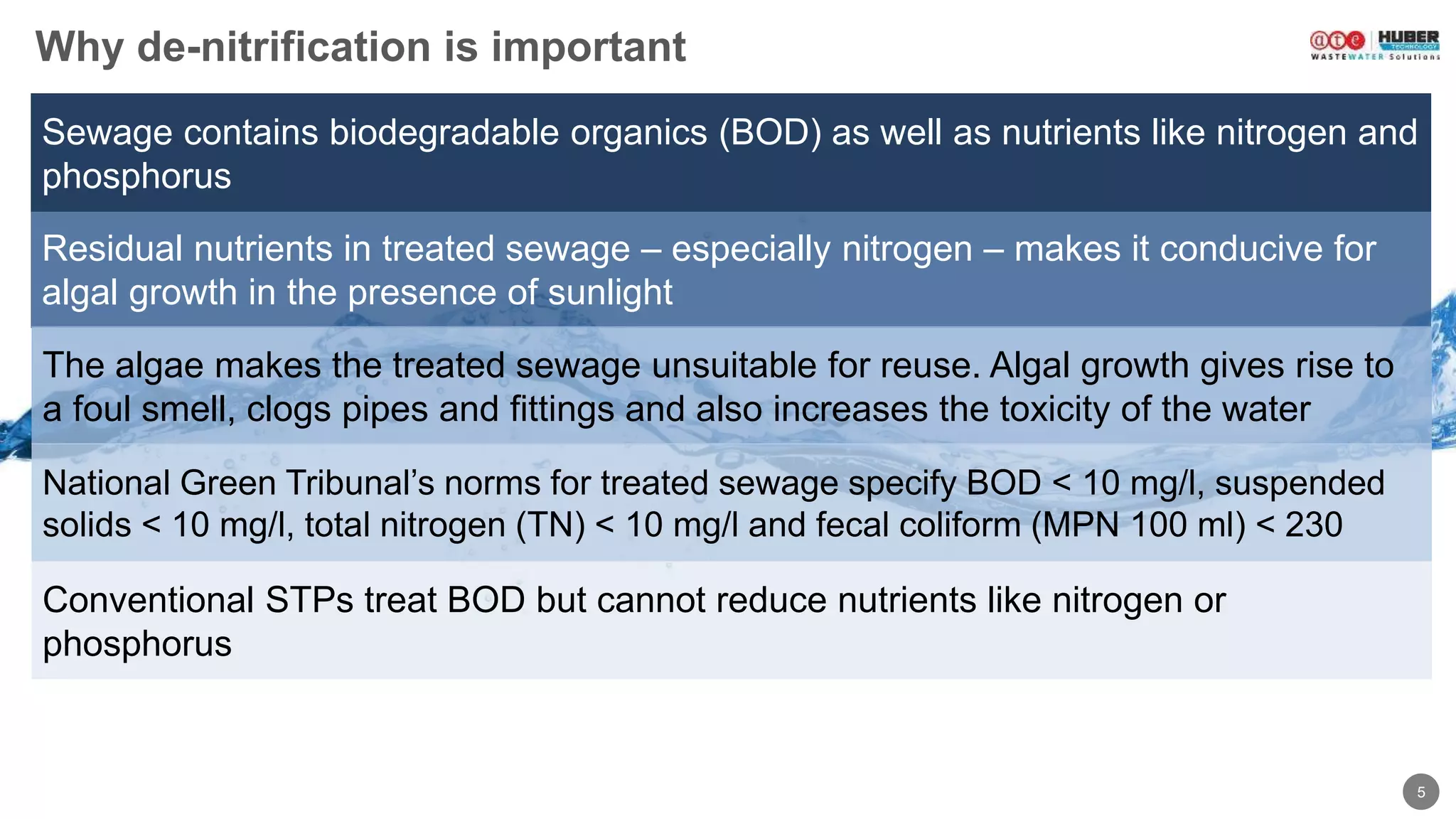

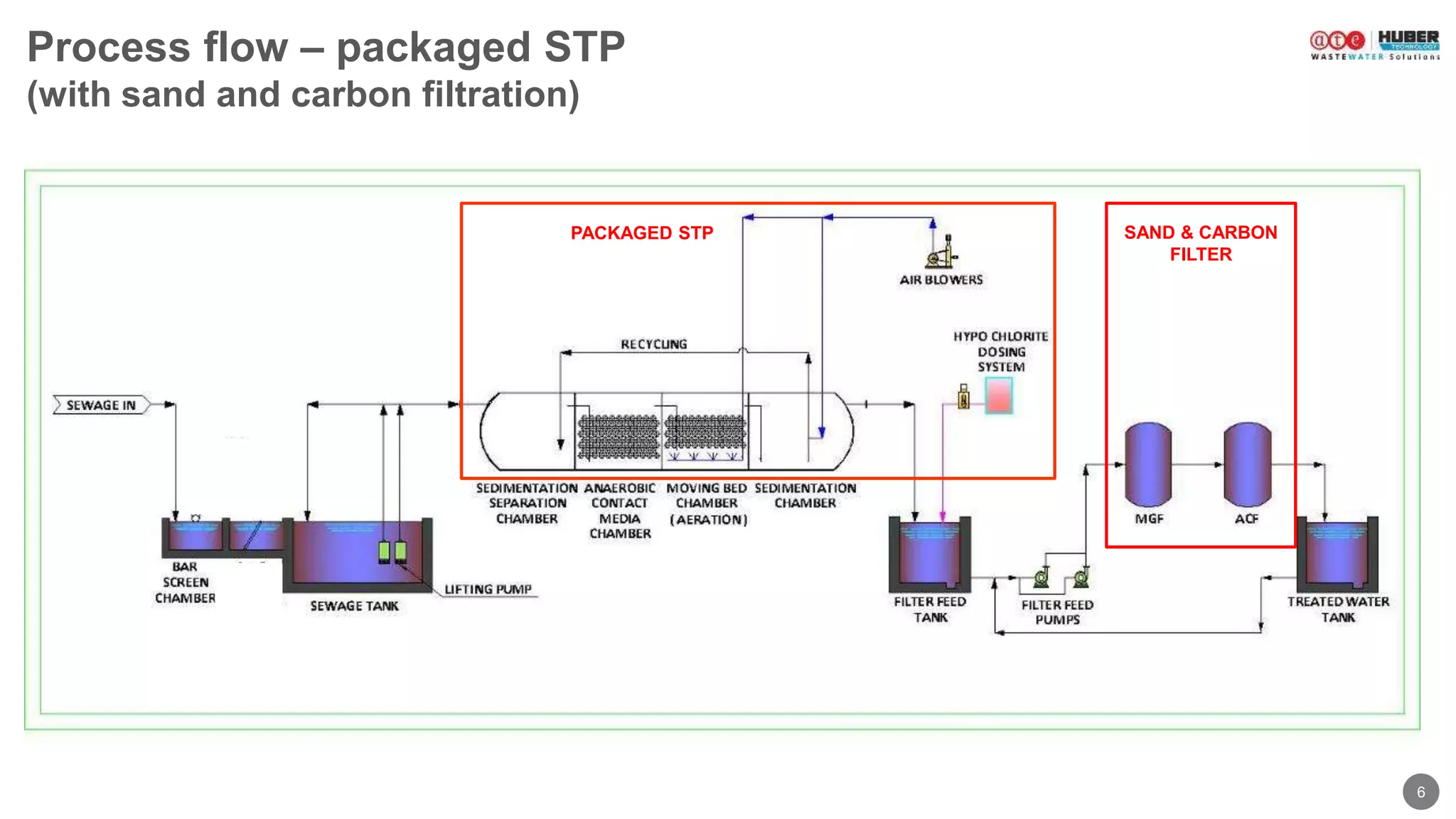

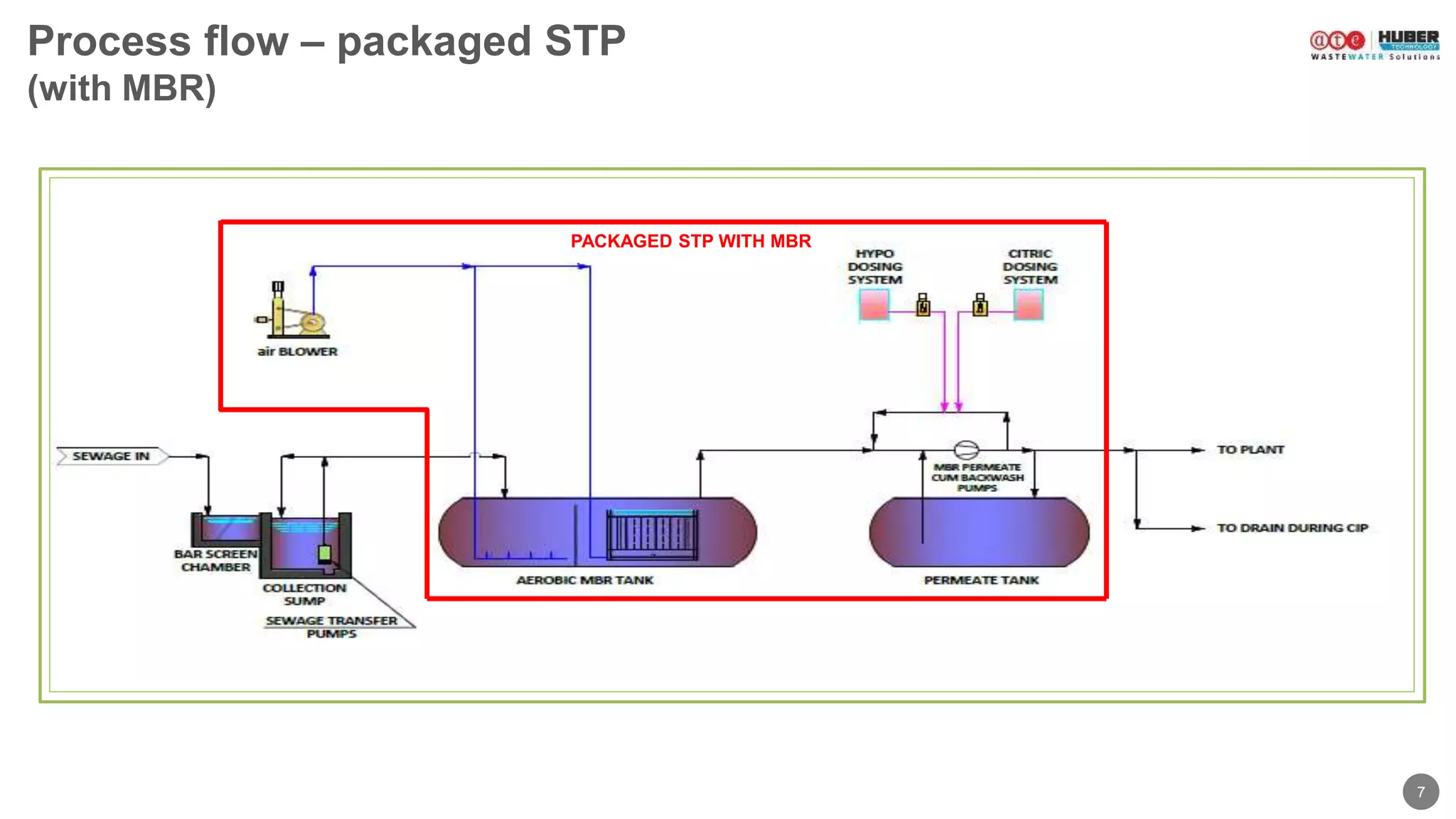

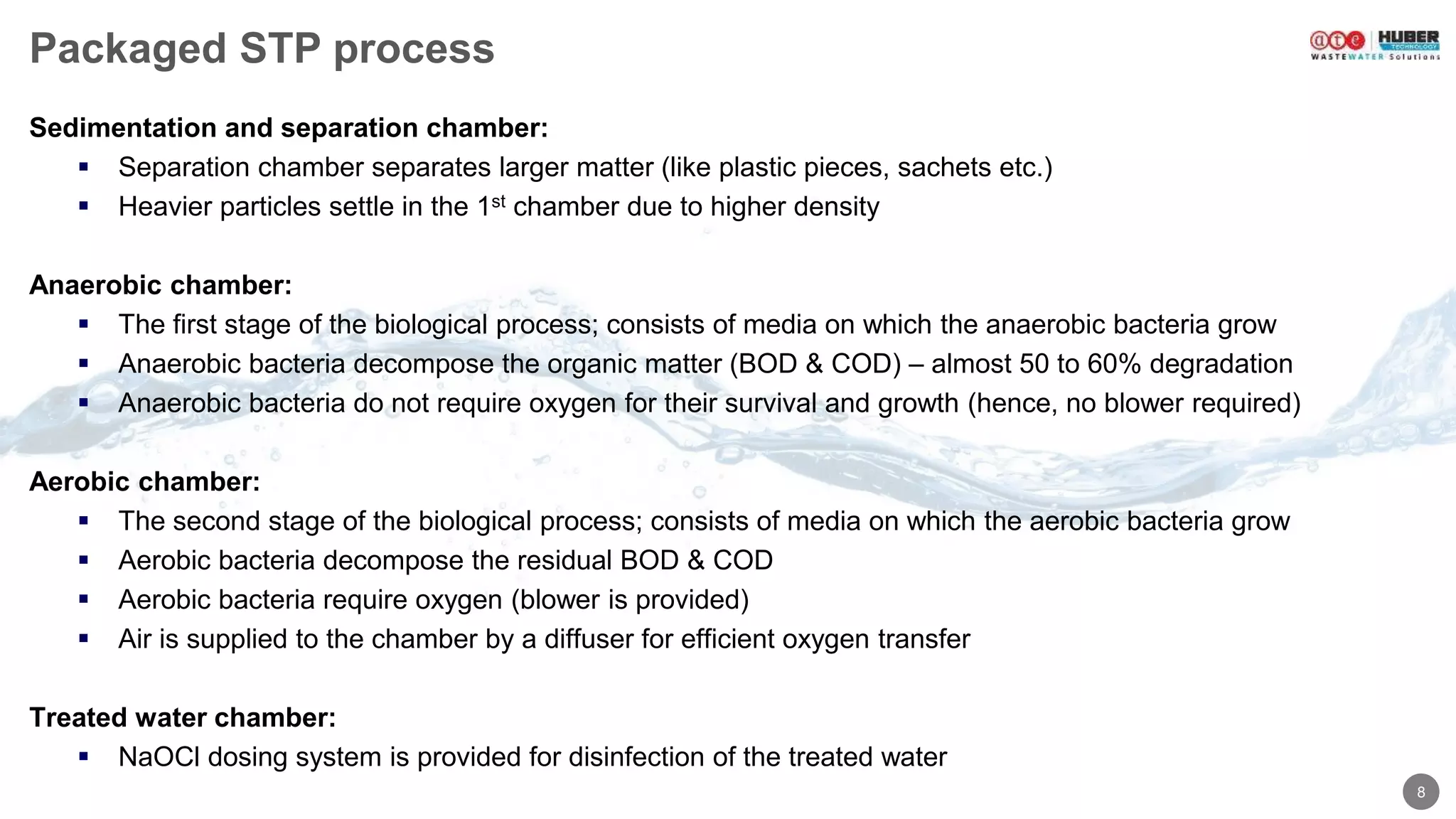

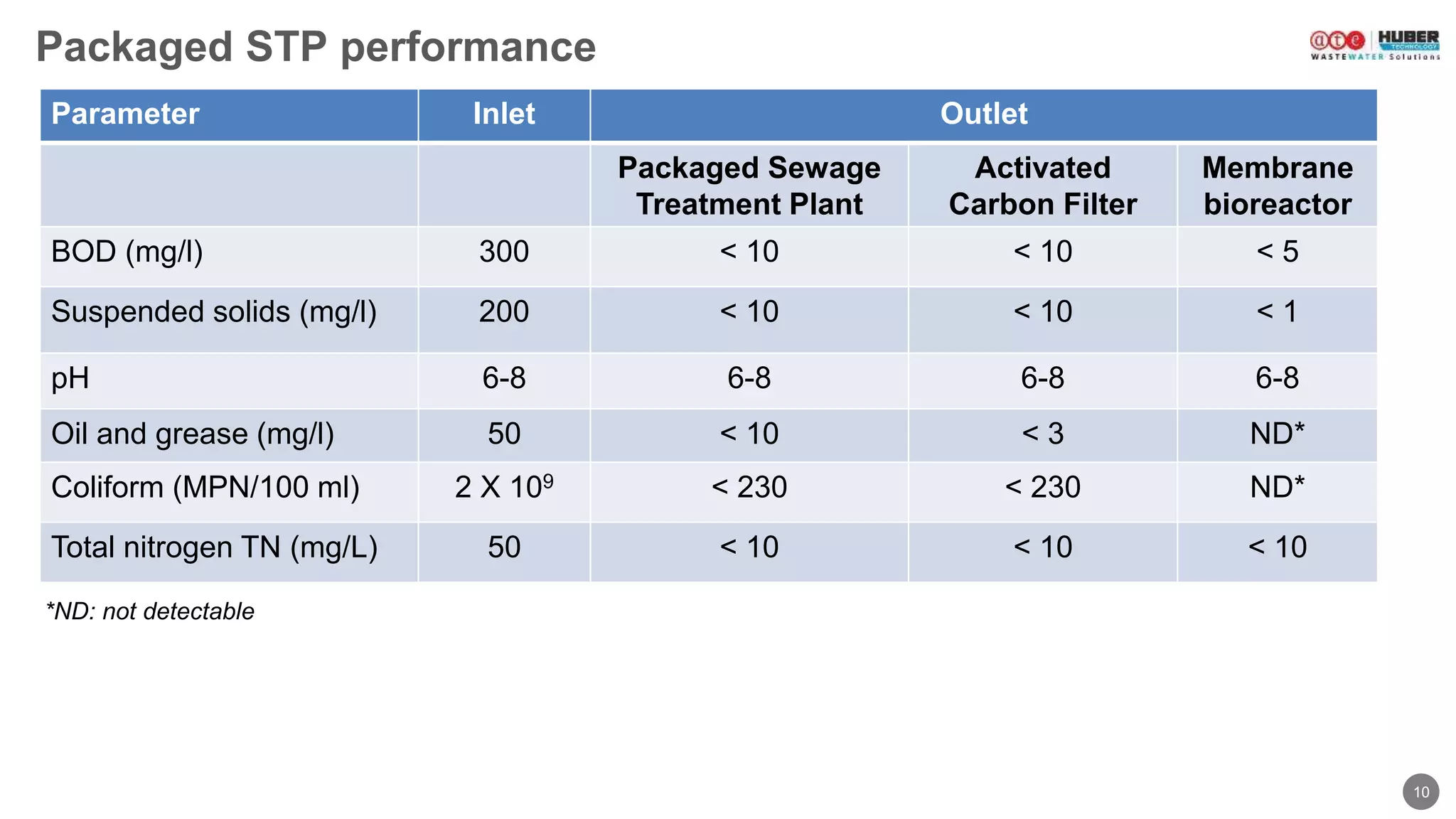

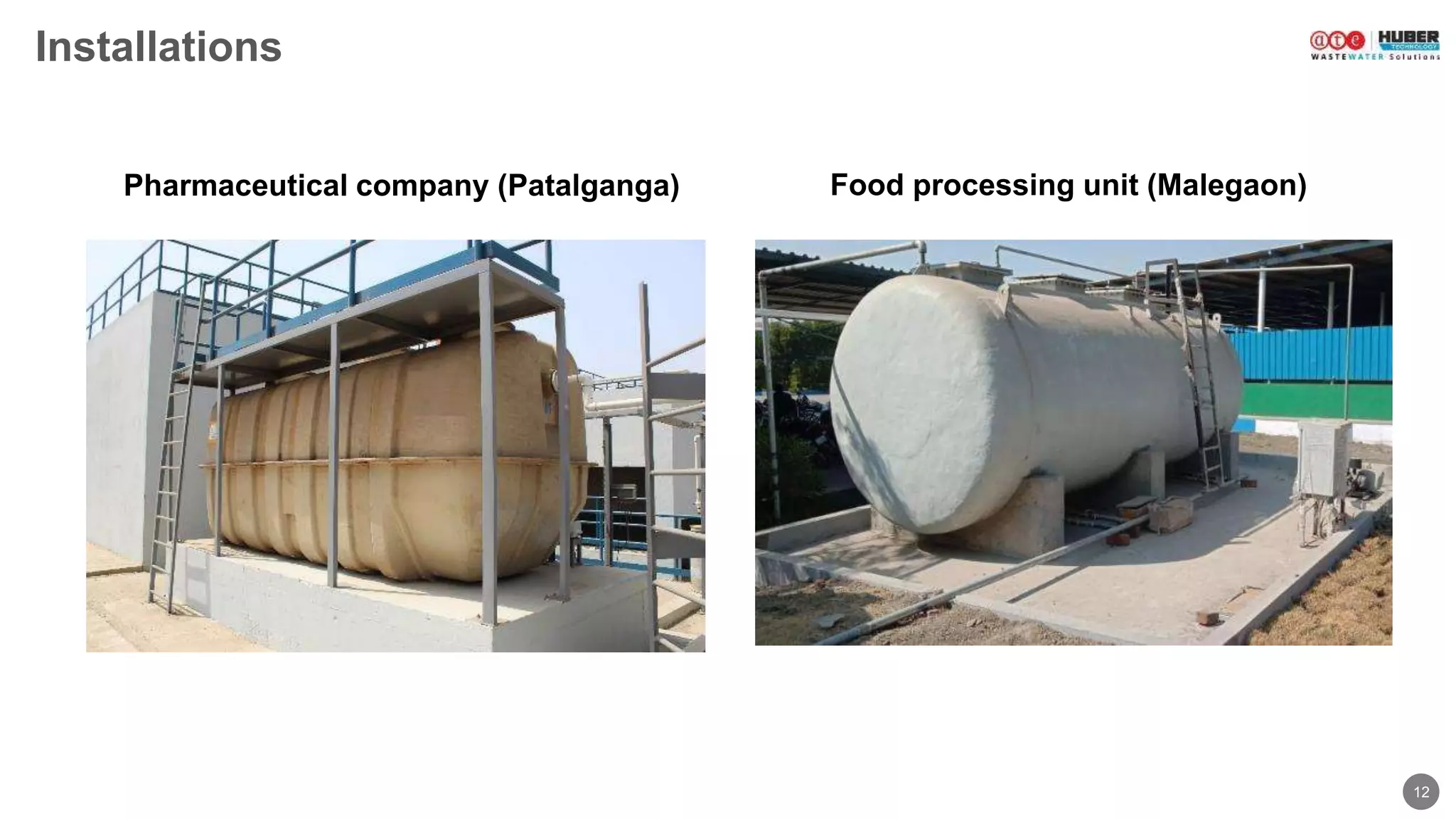

A.T.E. Huber Envirotech Private Limited specializes in industrial and municipal wastewater treatment, leveraging 180 years of experience from Huber SE and completing over 300 projects in 10 countries. They offer a range of solutions, including packaged sewage treatment plants with de-nitrification, designed to efficiently treat sewage while adhering to strict environmental standards. Their modular, compact systems optimize space and reduce power consumption, with advanced features such as membrane bio-reactors and comprehensive sludge management.