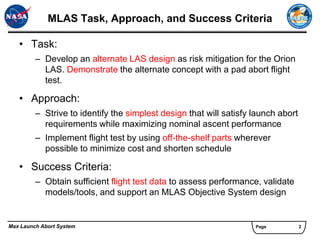

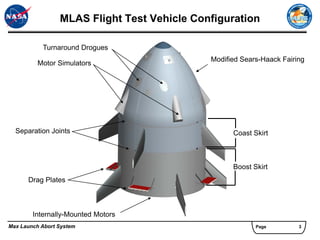

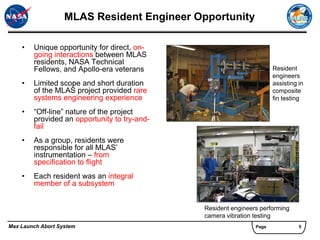

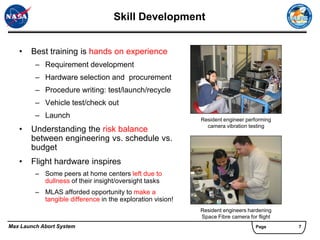

The document describes the Max Launch Abort System (MLAS) project which developed an alternative launch abort system design for Orion as a risk mitigation effort. The MLAS project aimed to identify the simplest design that maximized nominal ascent performance using off-the-shelf parts where possible. A key part of the project was a pad abort flight test to validate models and tools. The document discusses the MLAS flight test vehicle configuration, the flight test itself, opportunities for resident engineers, skill development experiences of the resident engineers, and technical lessons learned from the project.