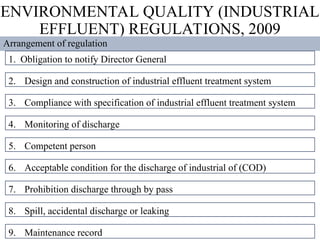

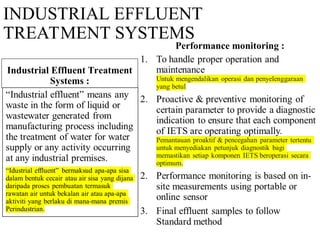

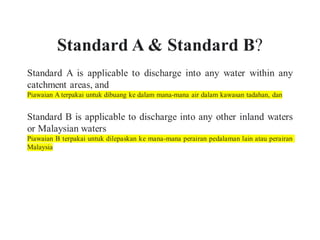

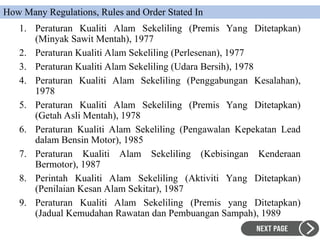

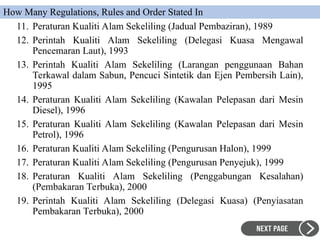

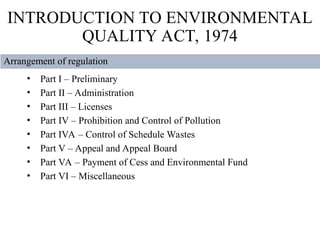

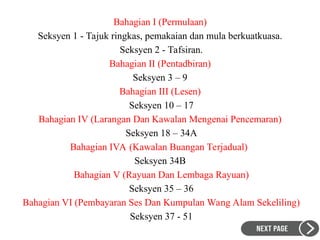

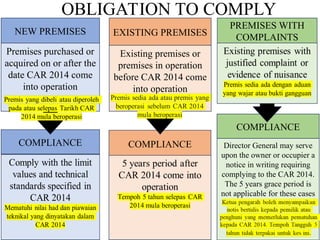

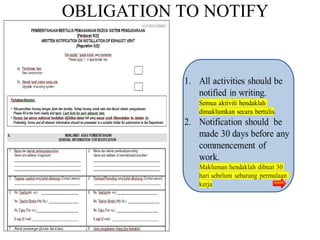

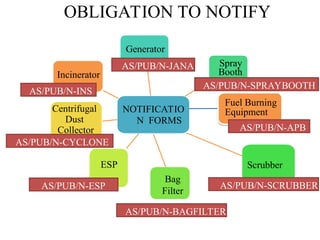

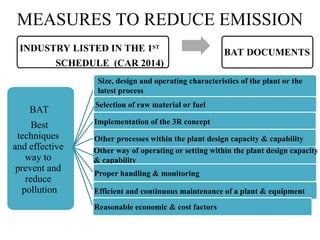

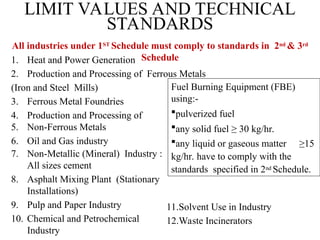

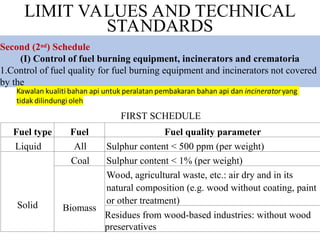

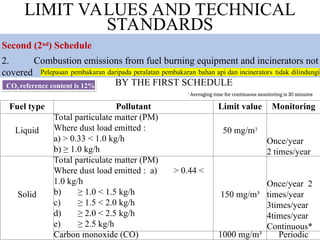

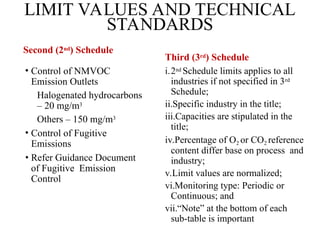

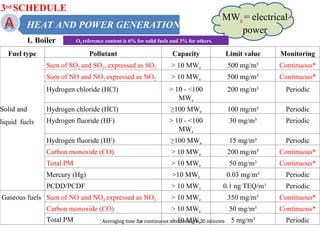

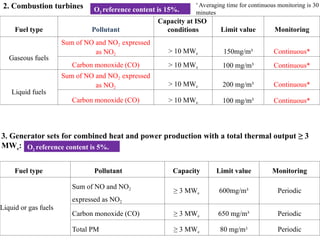

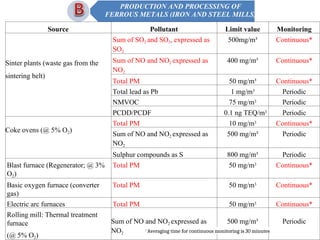

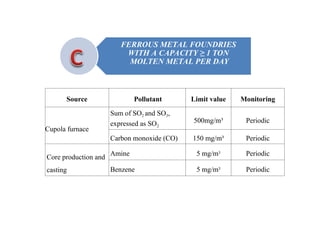

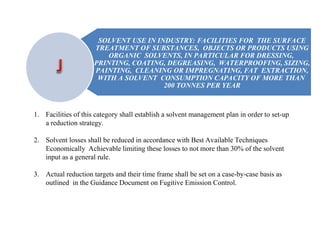

The document provides training on the Environmental Quality Act of 1974, detailing its purpose, sections, and regulations concerning pollution control in Malaysia. It outlines specific regulations for air quality, waste management, and compliance responsibilities for various industries. The training emphasizes the importance of adhering to established standards to mitigate environmental pollution.

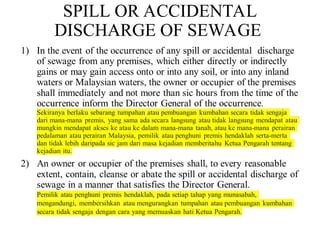

![Bacaan

normalized

pada STP

(273K,

101.3

kPa)

Tentukan

rujukan O2

yang

ditetapkan

Contoh :

Bagi loji janakuasa menggunakan bahanapi

pepejal, rujukan oksigen adalah 6% dan nilai

had pengeluaran NO2 adalah 500 mg/m3. Jika

bacaan yang diukur adalah 490 mg/m3 pada

bacaan oksigen 8%, maka bacaan yang diukur

perlu normalized dengan menggunakan formula

berikut:

O2, ref

[GN] 20.9

O2,

measured

= O2 reading, % vol

= reference oxygen content, % vol

[G] = measured gas concentration

= normalized gas concentration

= percentage of oxygen in ambient

air

2,measured

2,ref

20.9 O

GN G

20.9

O

3

m

G N

566 mg

20.9 8

490

20.9 6](https://image.slidesharecdn.com/eqa-240823151718-8e909bf8/85/Environment-Quality-Act-slide-in-power-point-ppt-56-320.jpg)

![Bacaan

normalized

pada STP

(273K,

101.3

kPa)

Tentukan

rujukan

CO2

adalah

12%

Contoh :

Bagi pelepasan daripada peralatan pembakaran bahanapi yang menggunakan bahanapi

pepejal, rujukan karbon dioksida adalah 12% dan nilai had pengeluaran jirim zarahan

(PM) adalah 150 mg/m3. Jika bacaan yang diukur adalah 140 mg/m3 pada bacaan karbon

dioksida 8%, maka:

CO2, ref

N

CO

CO2,ref

2,measured

G

G

12

210 mg

m3

GN 140

8

PELEPASAN KARBON

MONOKSIDA

CO2, measured = CO2 measured, % vol

= reference carbon dioxide content, %

vol

[G] = measured gas

concentrDatitioentapkan mengikut

keperluan

[GN] = normalized gas

concent(rcaatiosen to case basis) bagi

proses

yang memerlukan pembakaran

tidak lengkap seperti kilang

penghasilan kayu arang (kiln)](https://image.slidesharecdn.com/eqa-240823151718-8e909bf8/85/Environment-Quality-Act-slide-in-power-point-ppt-57-320.jpg)