These regulations establish standards and requirements for industrial effluent discharge in Malaysia. They require industries that discharge effluent to:

1. Notify authorities of new or changed discharge sources and treat effluent according to approved standards.

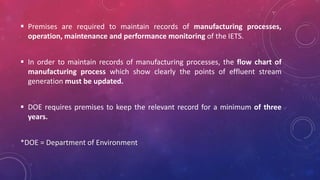

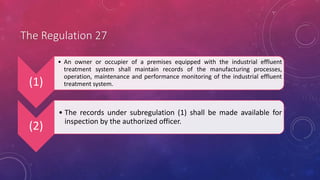

2. Monitor effluent quality and quantity, maintain records, and submit monitoring reports.

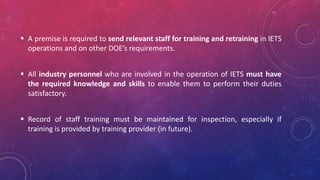

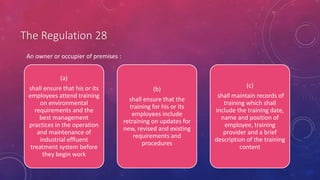

3. Operate and maintain effluent treatment systems properly using competent supervisors, and conduct performance monitoring according to guidelines.

The regulations specify effluent quality standards, record keeping and personnel training requirements to control pollution from industrial sources.

![ Sludge - any deposit of particulate matter settled from any liquid, including

deposit resulting from physical, chemical and biological.

Professional engineer - has the same meaning assigned to it in the

Registration of Engineers Act 1967 [Act 138].

Sewage - any liquid waste or wastewater discharge containing human, animal,

domestic and includes liquids containing chemicals in solution either in the

raw, treated or partially treated form.

Parameter - chemical oxygen demand or any of the factors shown in the first

column of the Fifth Schedule or in the Ninth Schedule.](https://image.slidesharecdn.com/enviregulations1-210909102543/85/Environmental-regulations-2009-6-320.jpg)