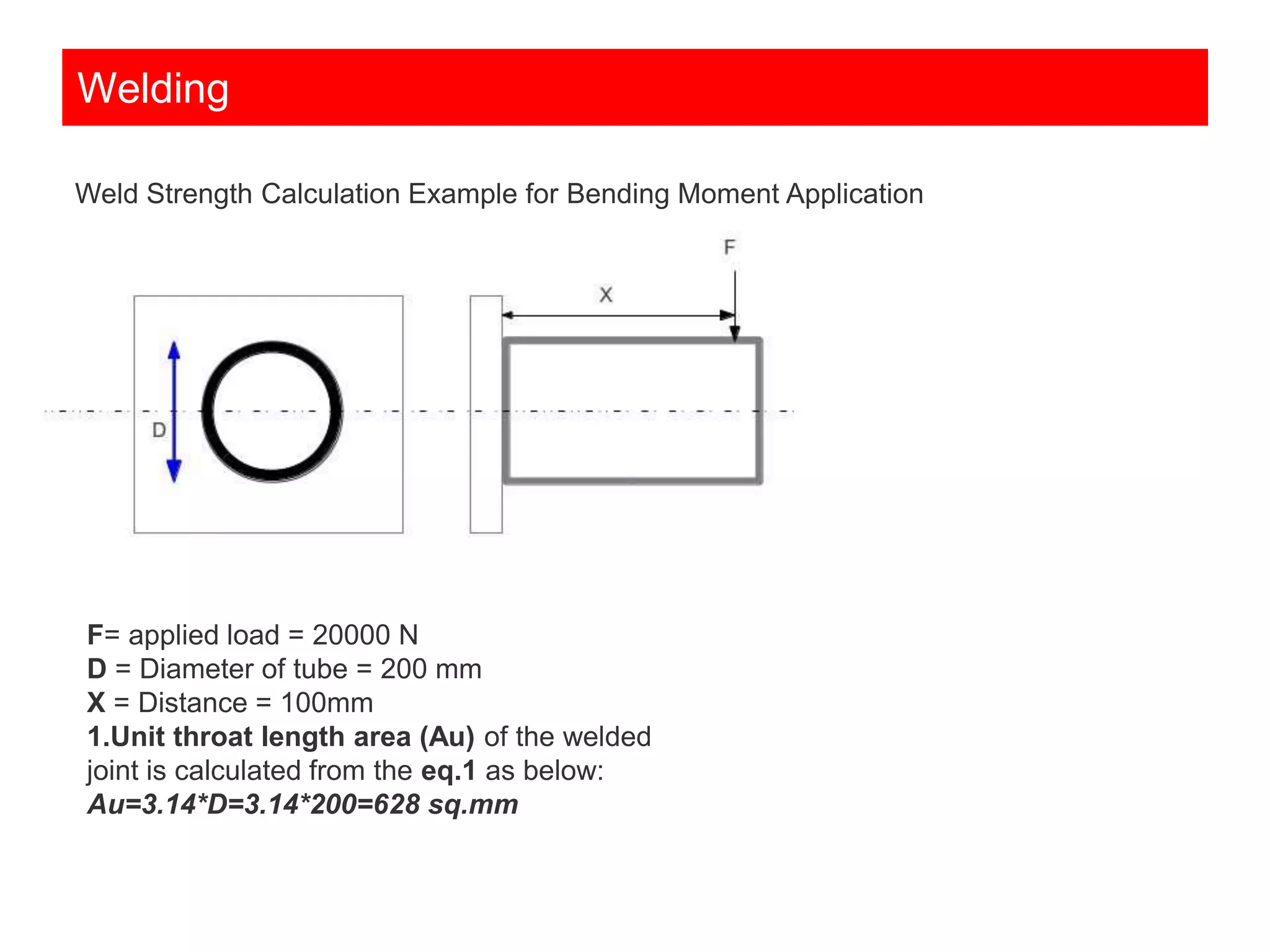

This document discusses welding techniques and principles. It covers various welding defects like porosity, cracking, undercut and burn through. It explains the common causes of these defects and potential remedies. The document also provides examples of evaluating welds for bending and torsion loads. Overall, it serves as a guide for welding processes and how to minimize defects.