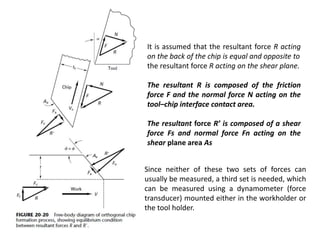

This document provides an overview of fundamental machining processes including turning, milling, drilling, broaching, and shaping. It discusses key concepts such as chip formation, cutting forces, tool angles, friction at tool-chip interfaces, and sources of chatter vibration. Examples are provided to calculate speeds, feeds, cutting times, and metal removal rates for different machining setups and operations.