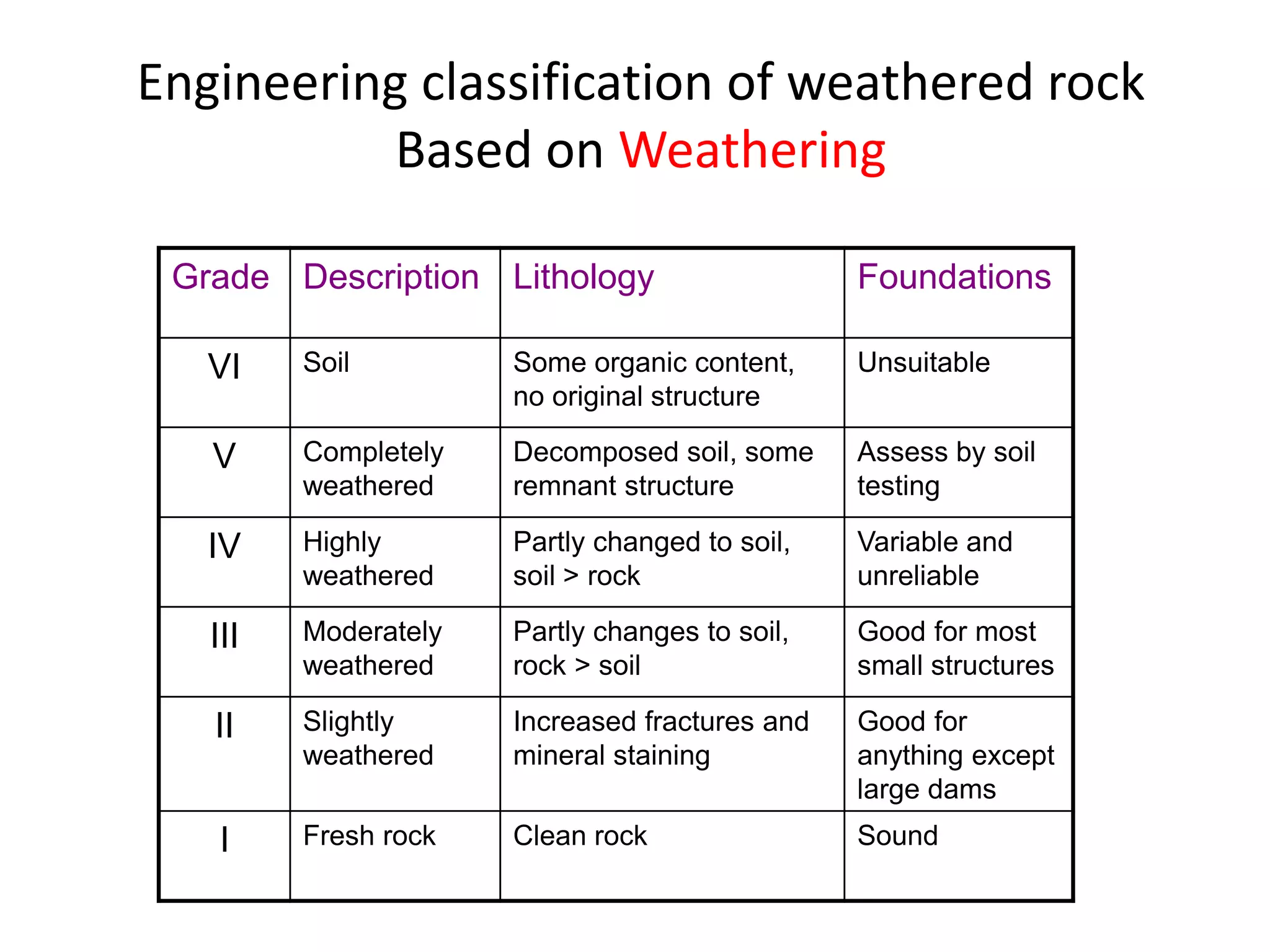

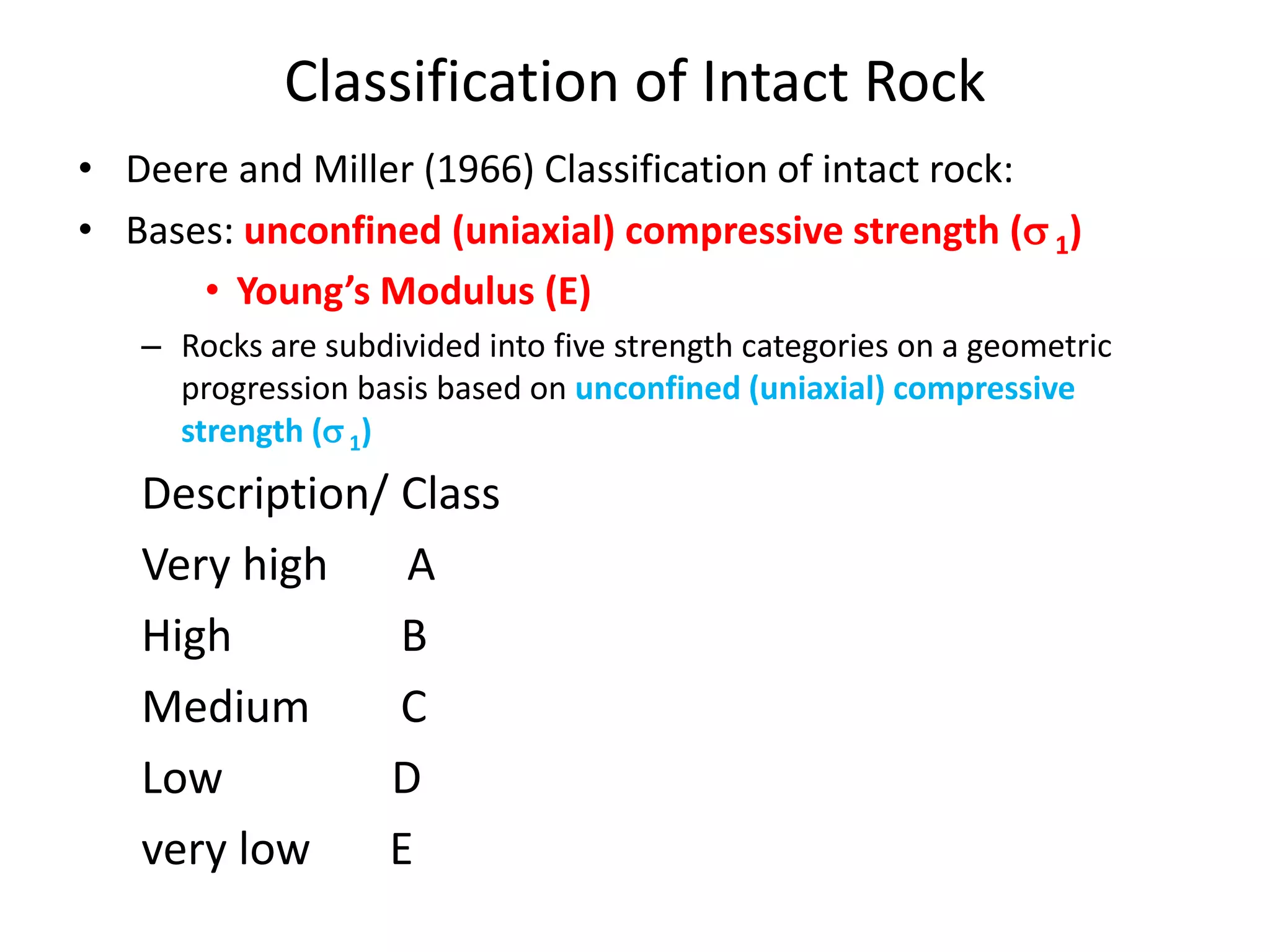

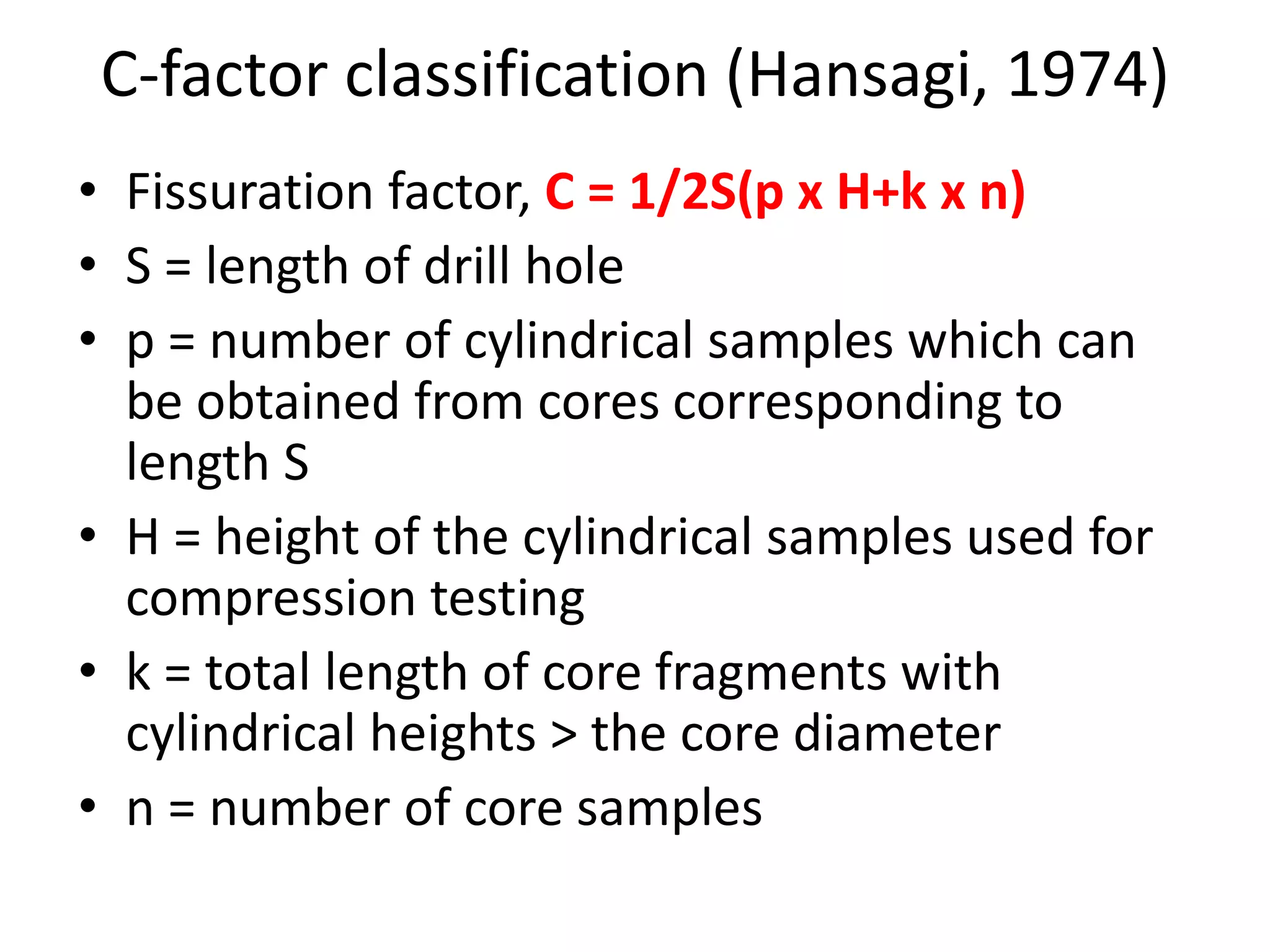

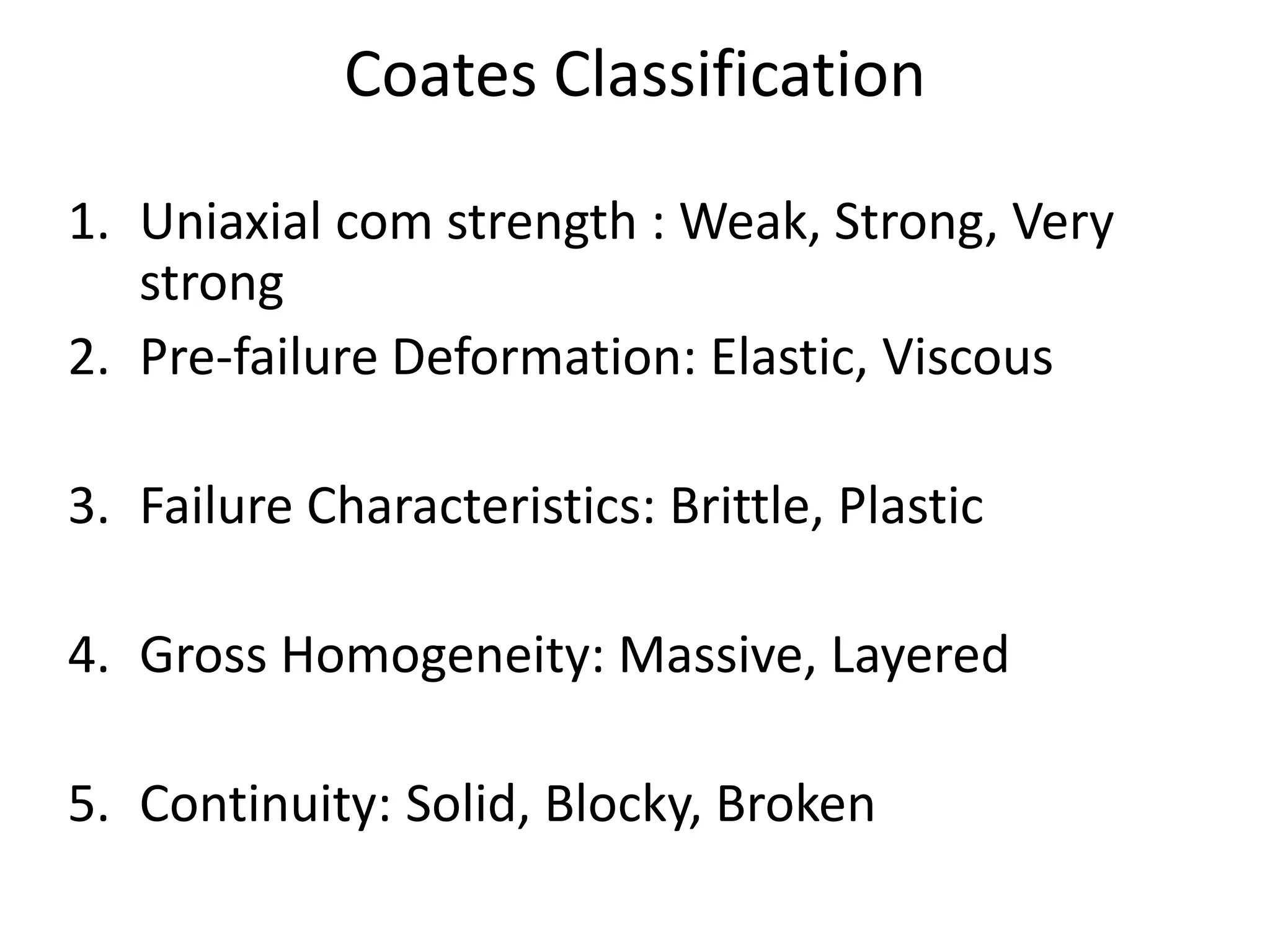

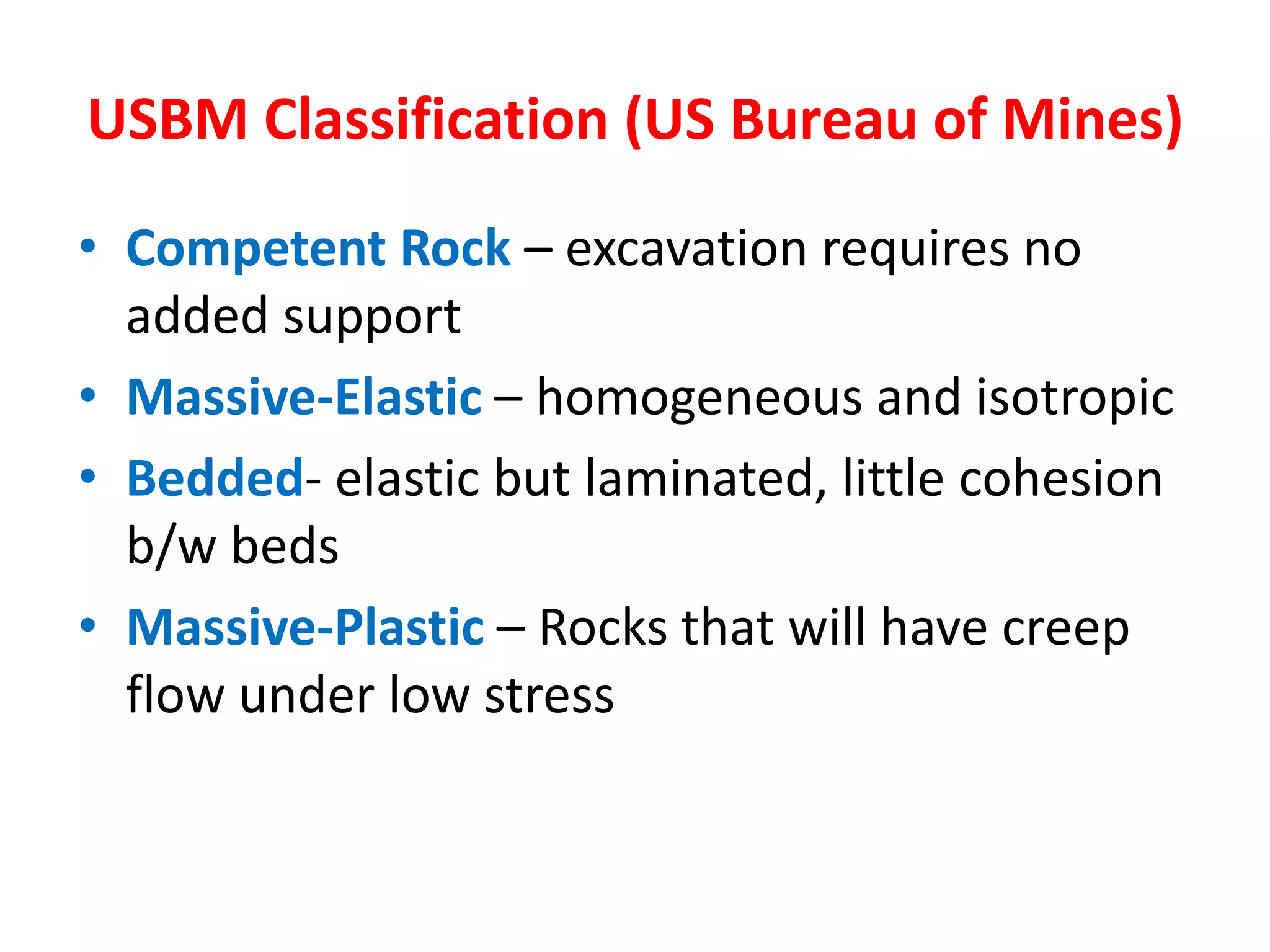

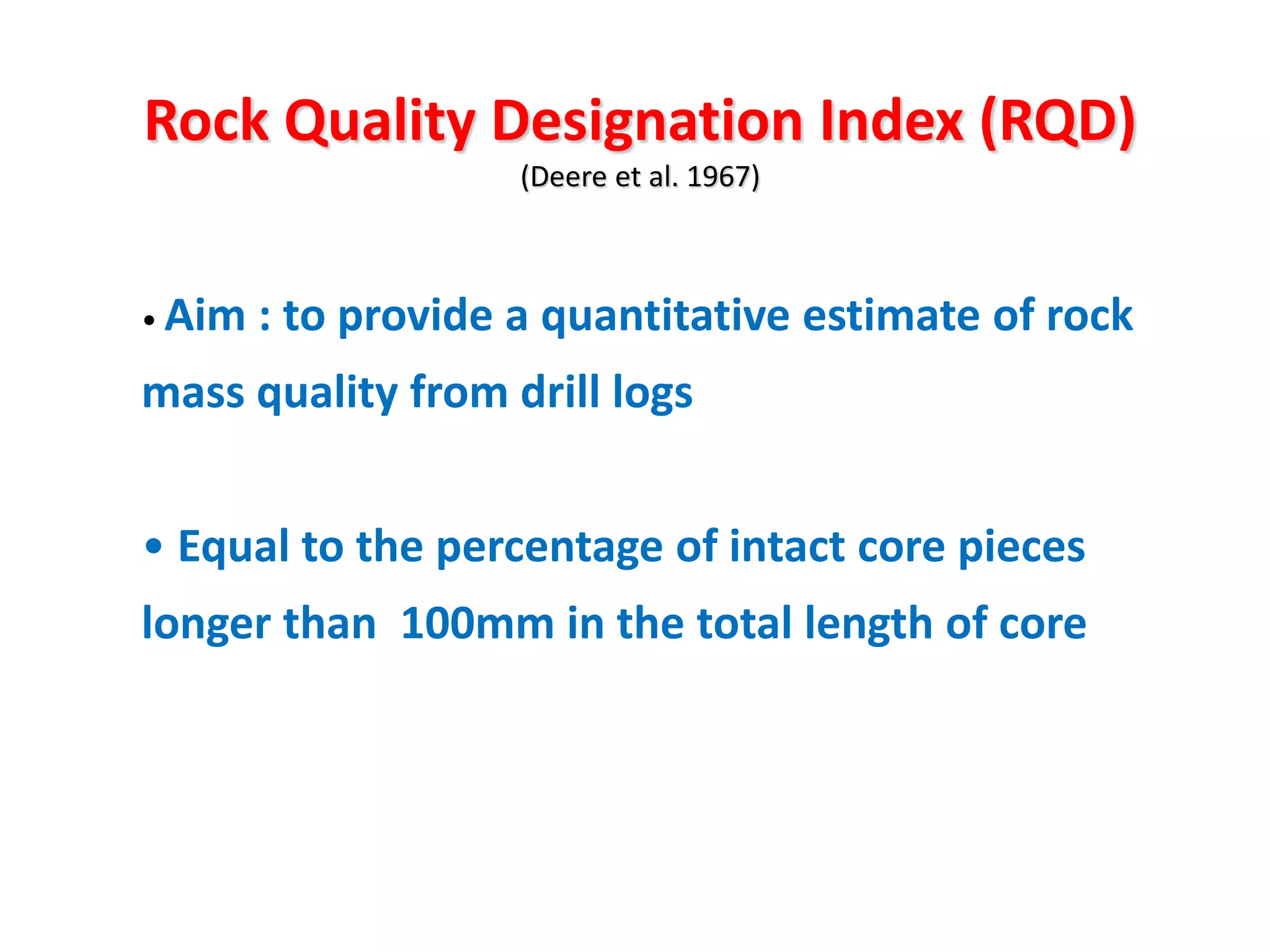

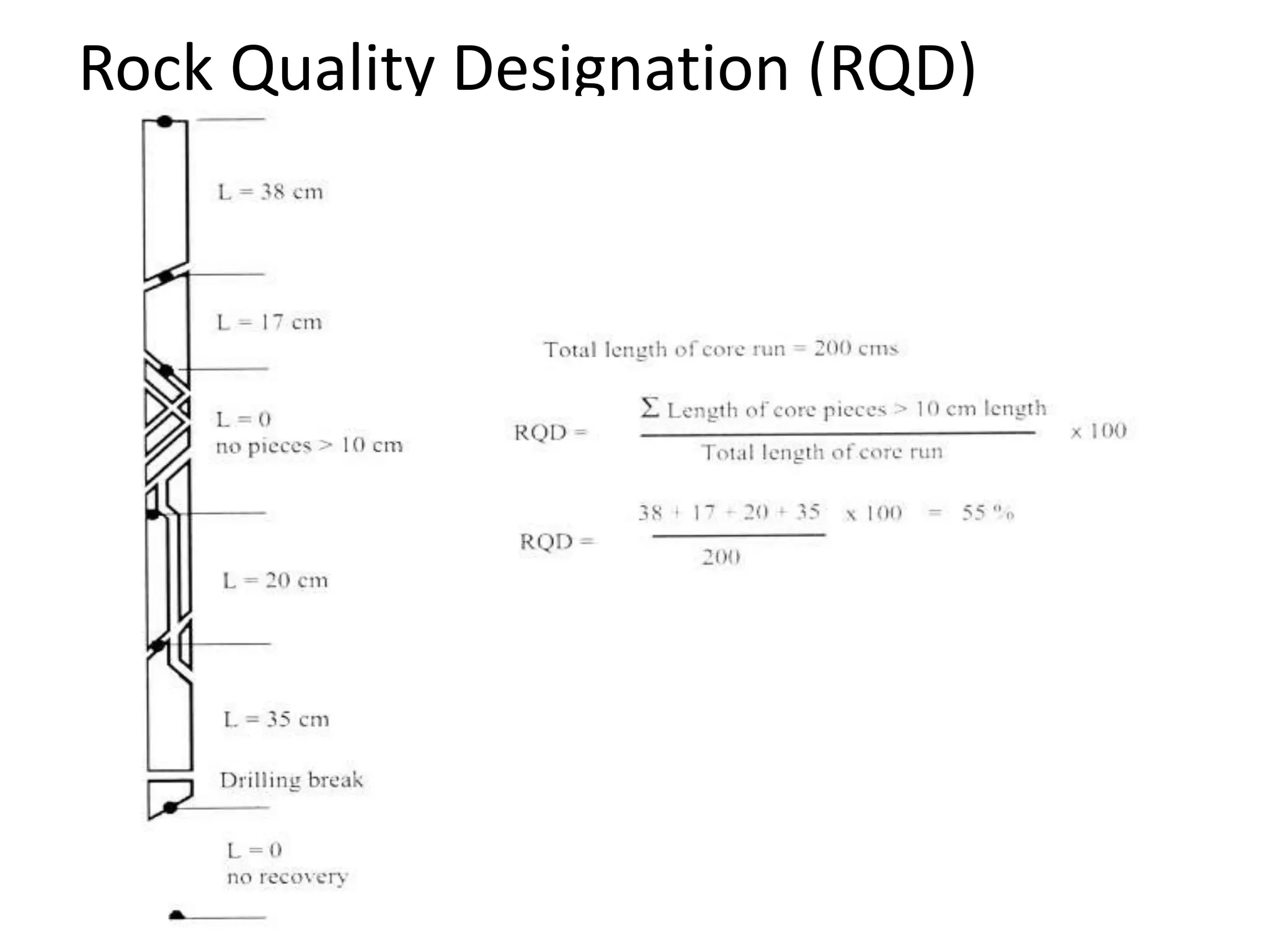

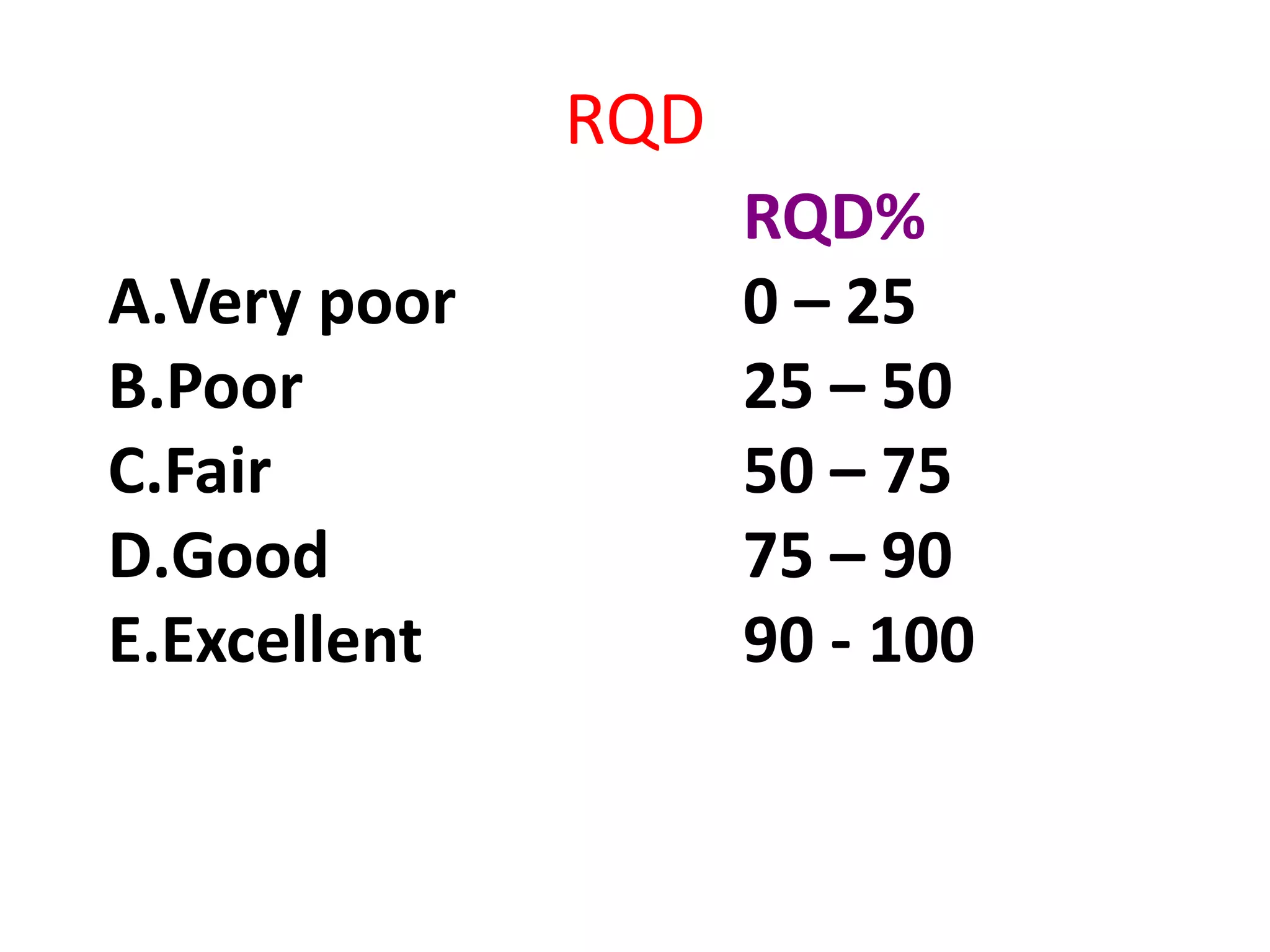

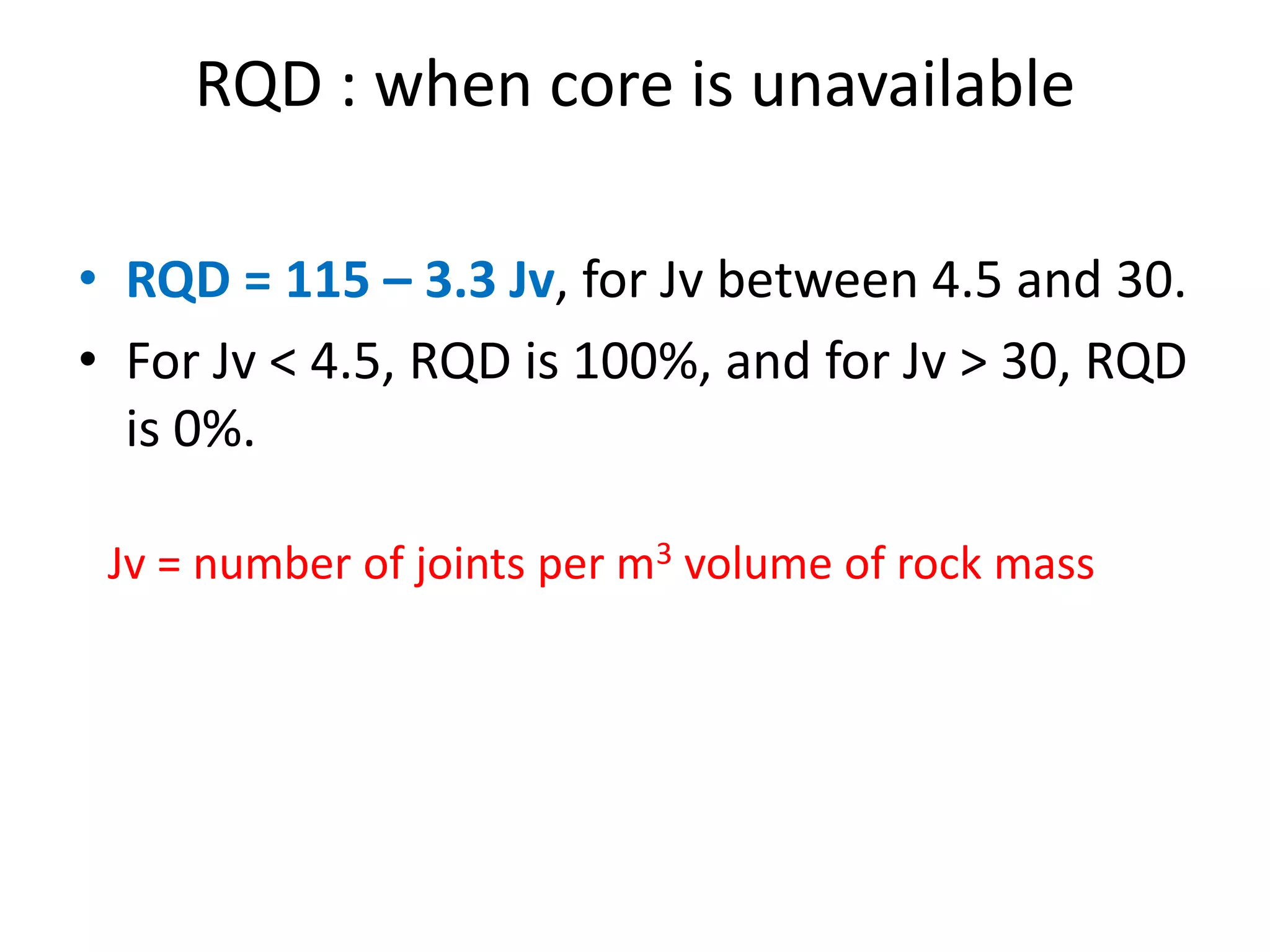

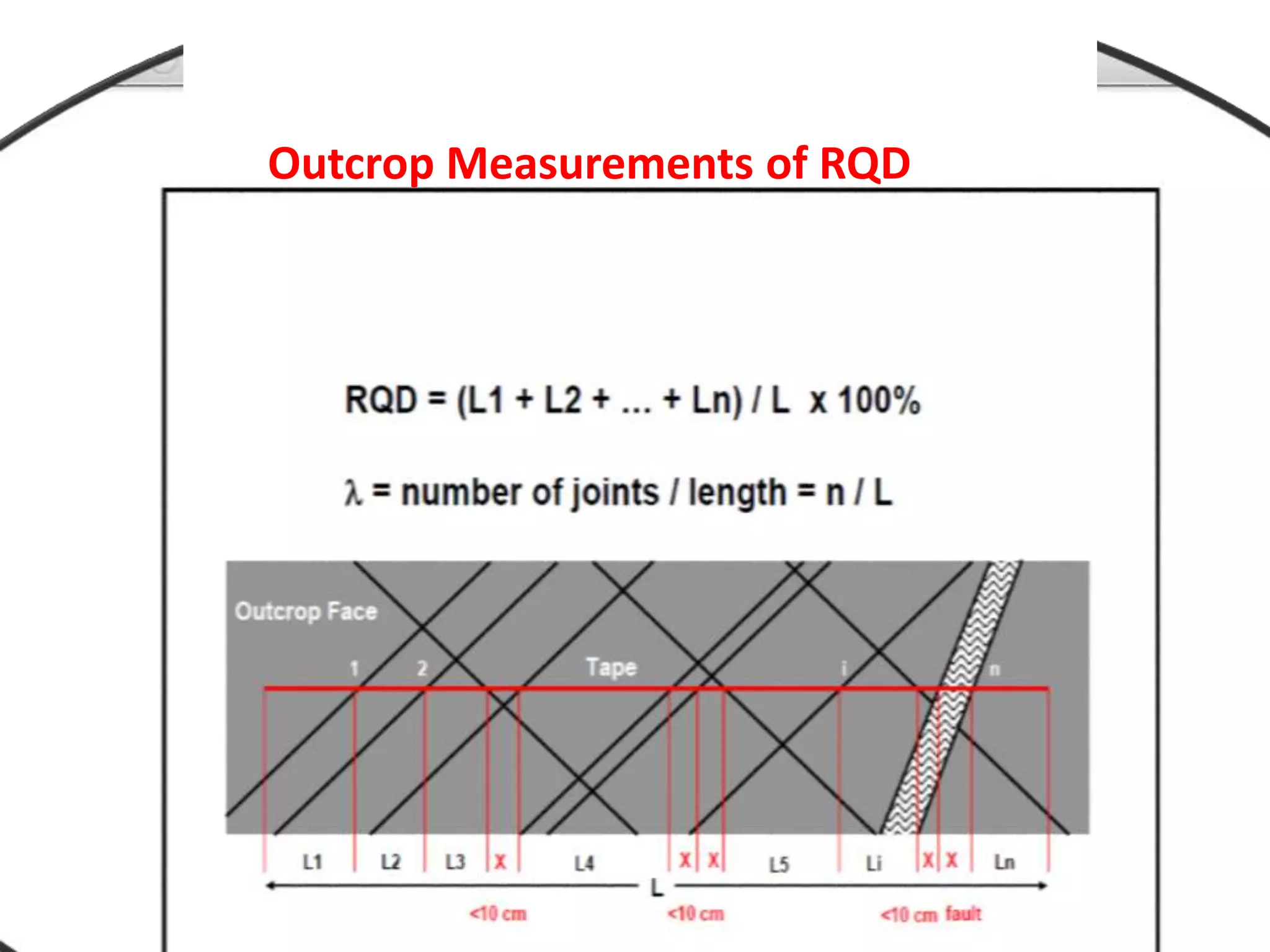

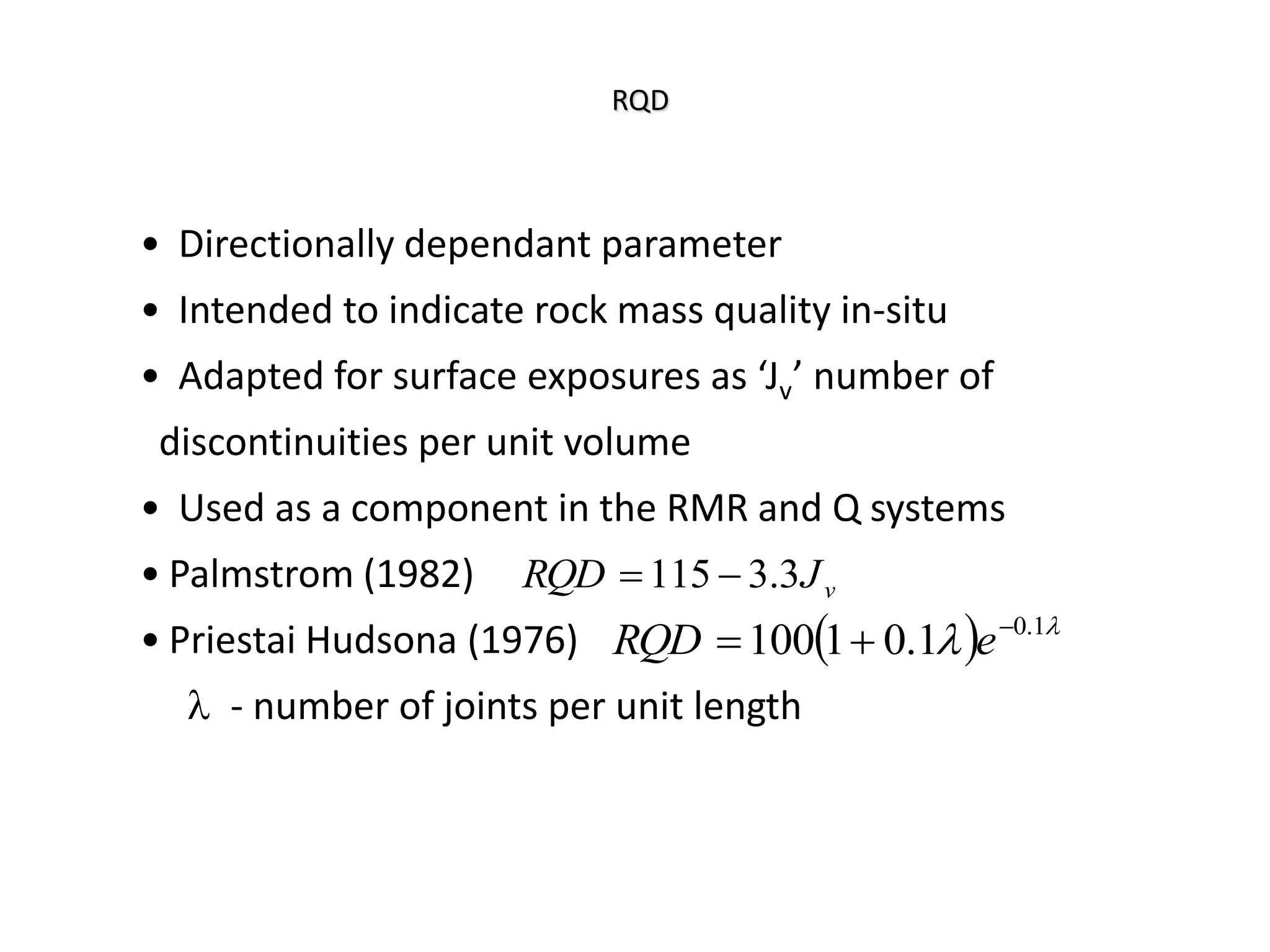

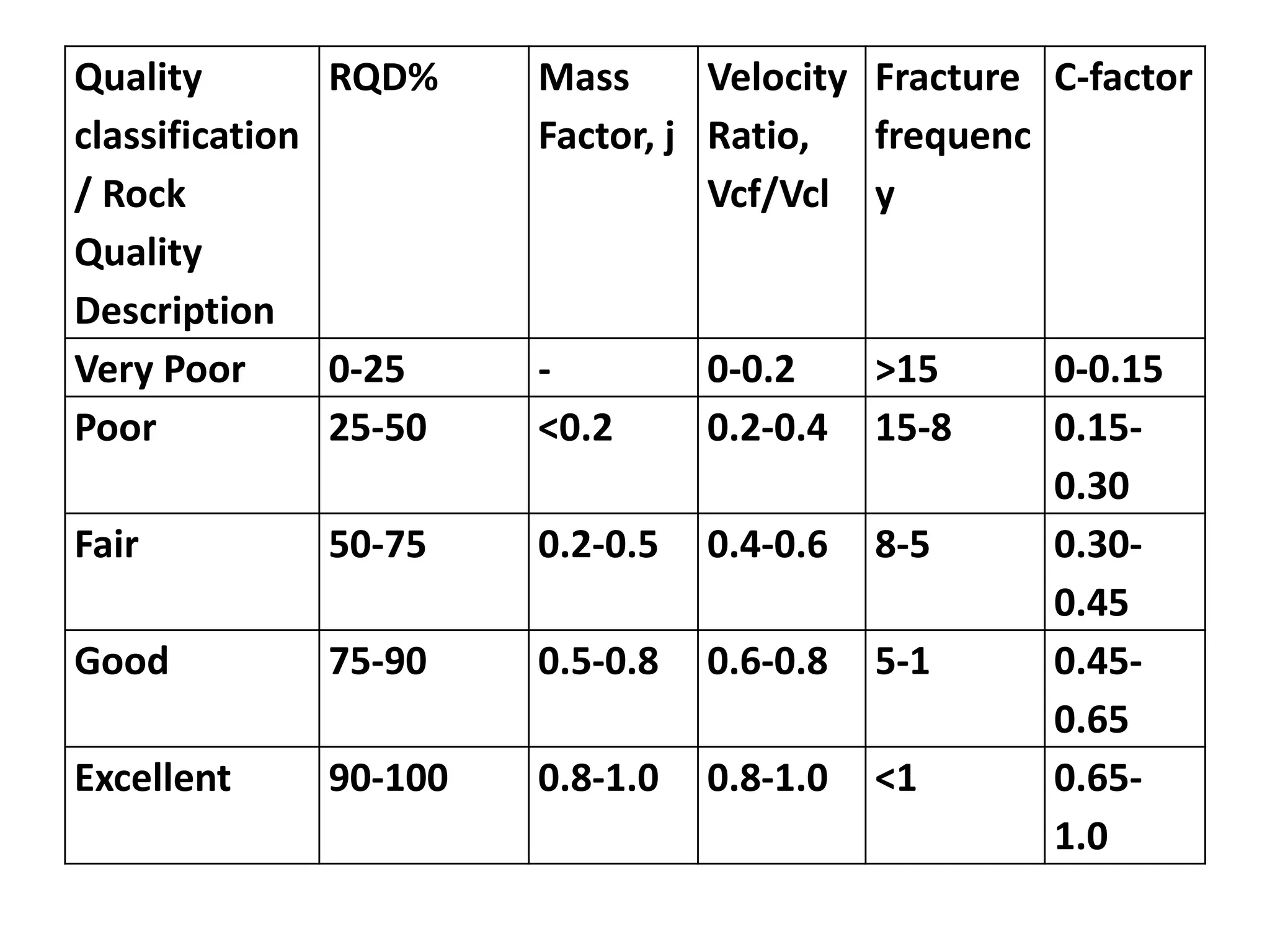

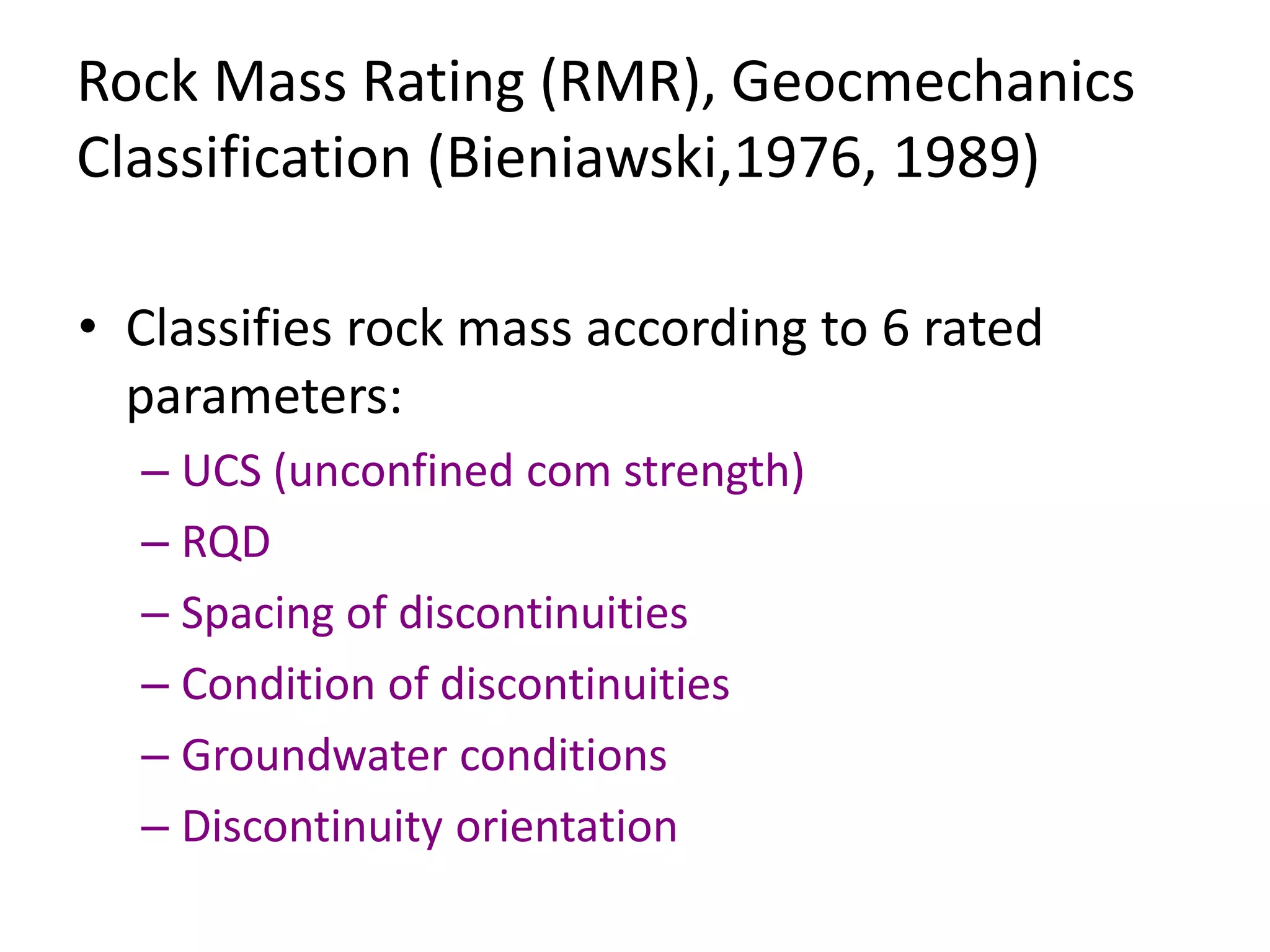

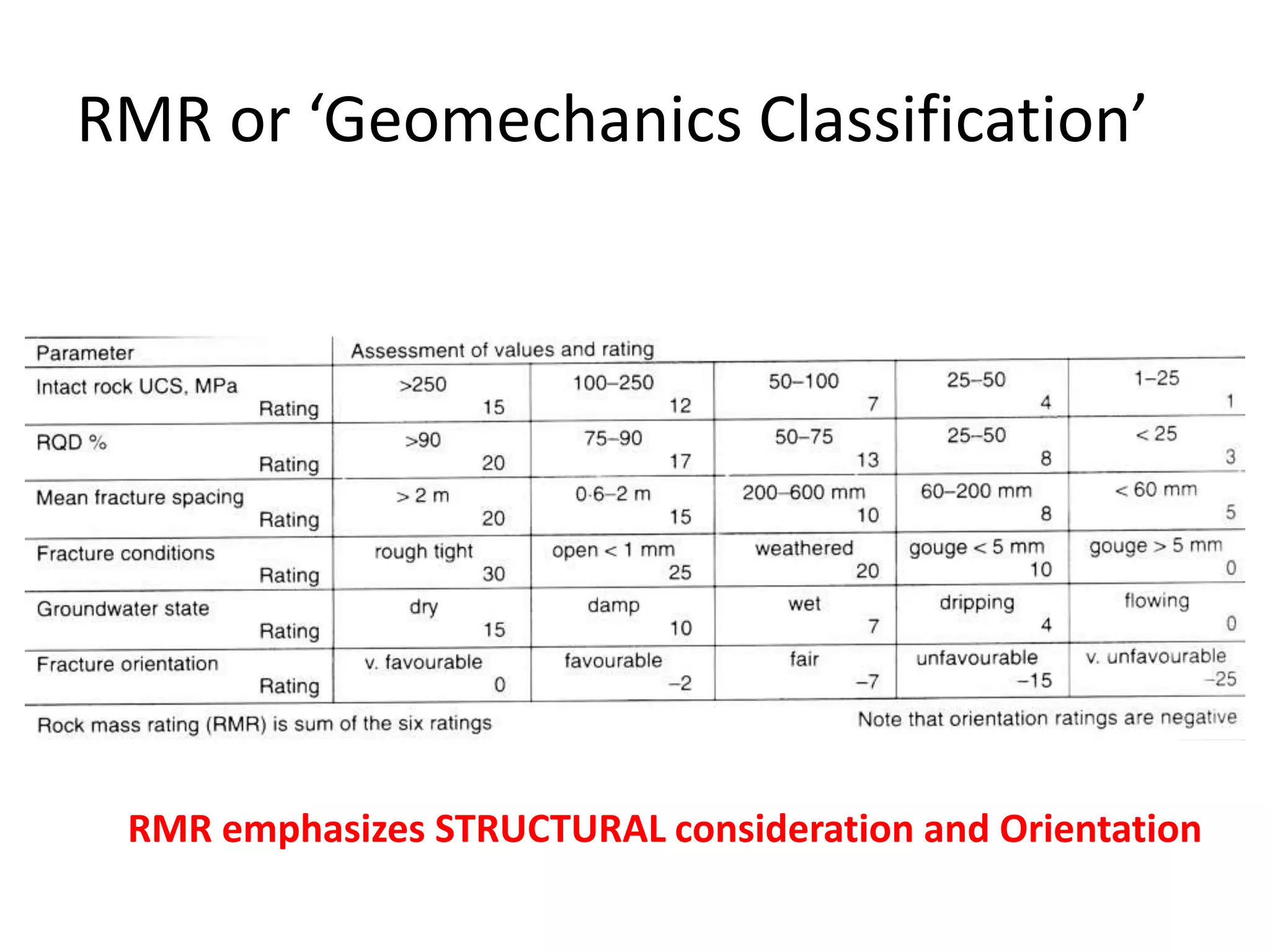

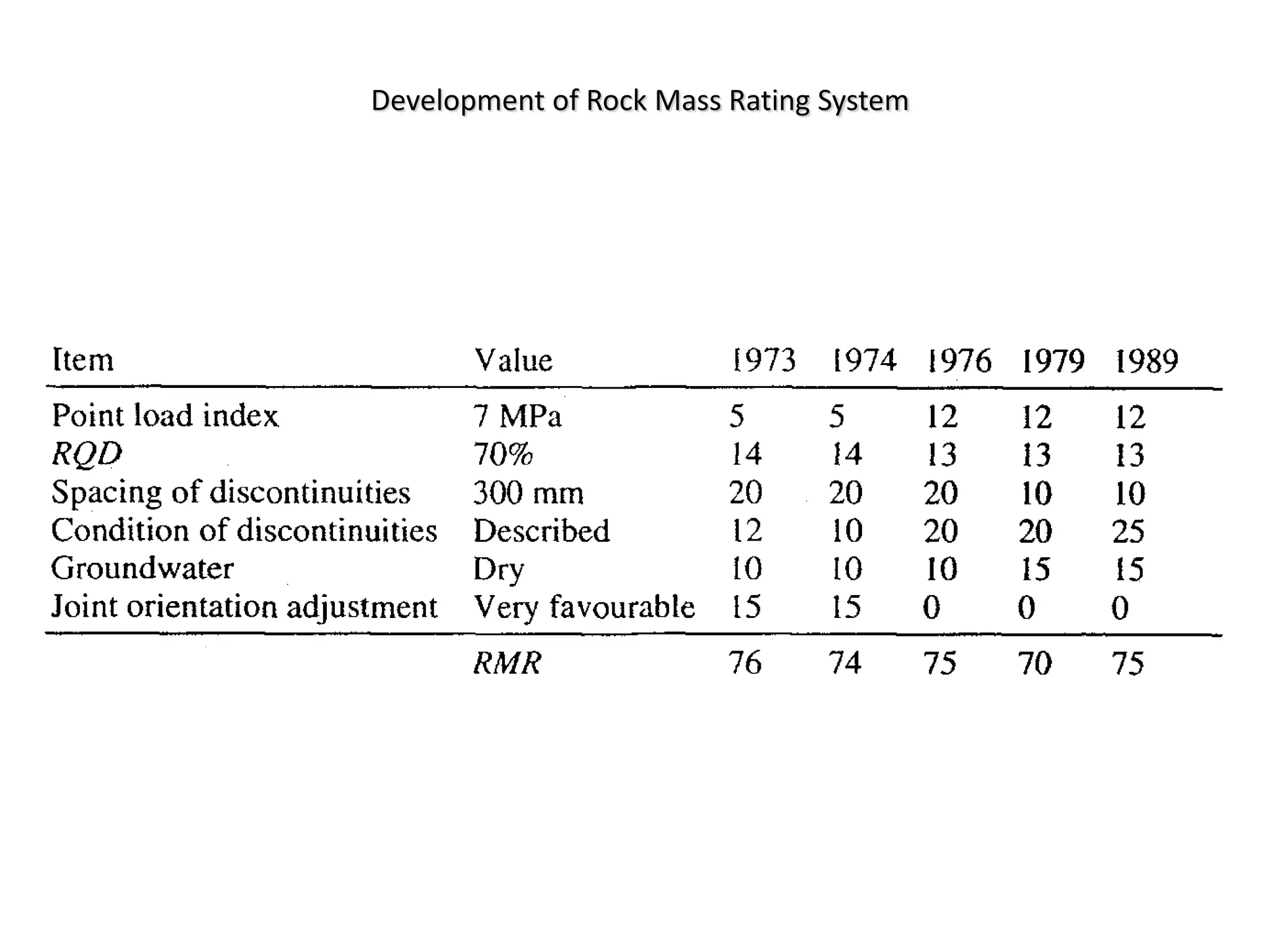

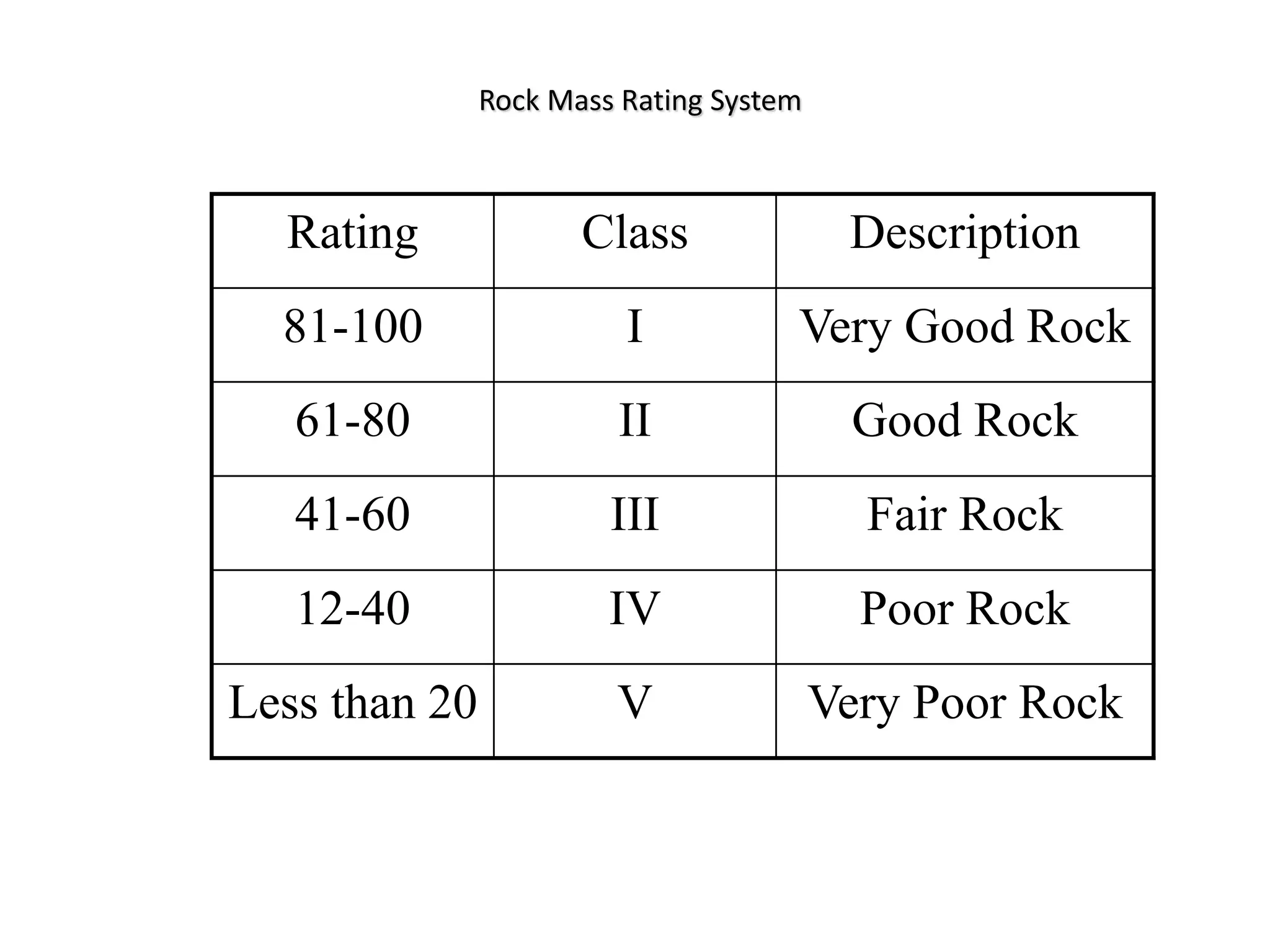

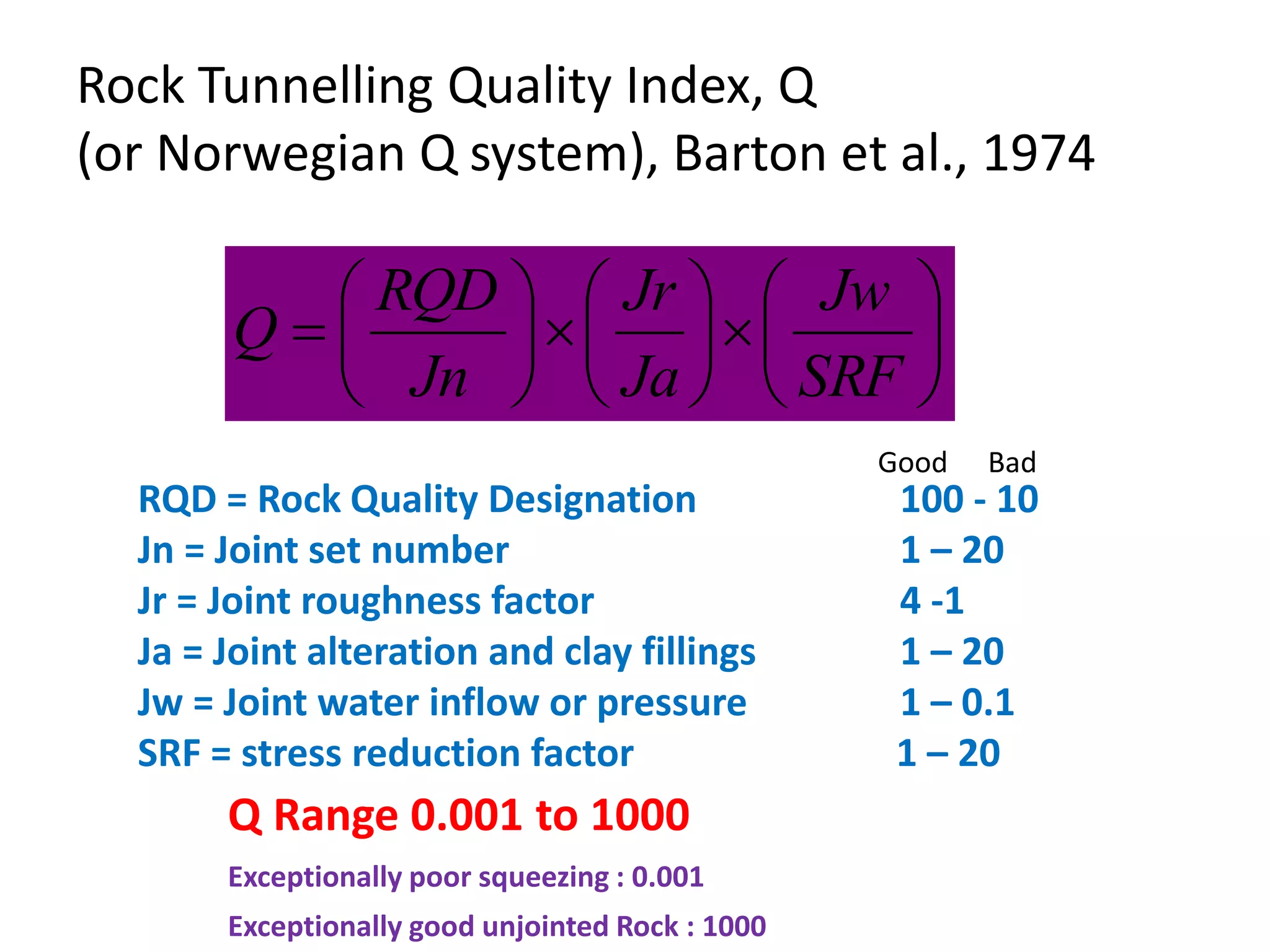

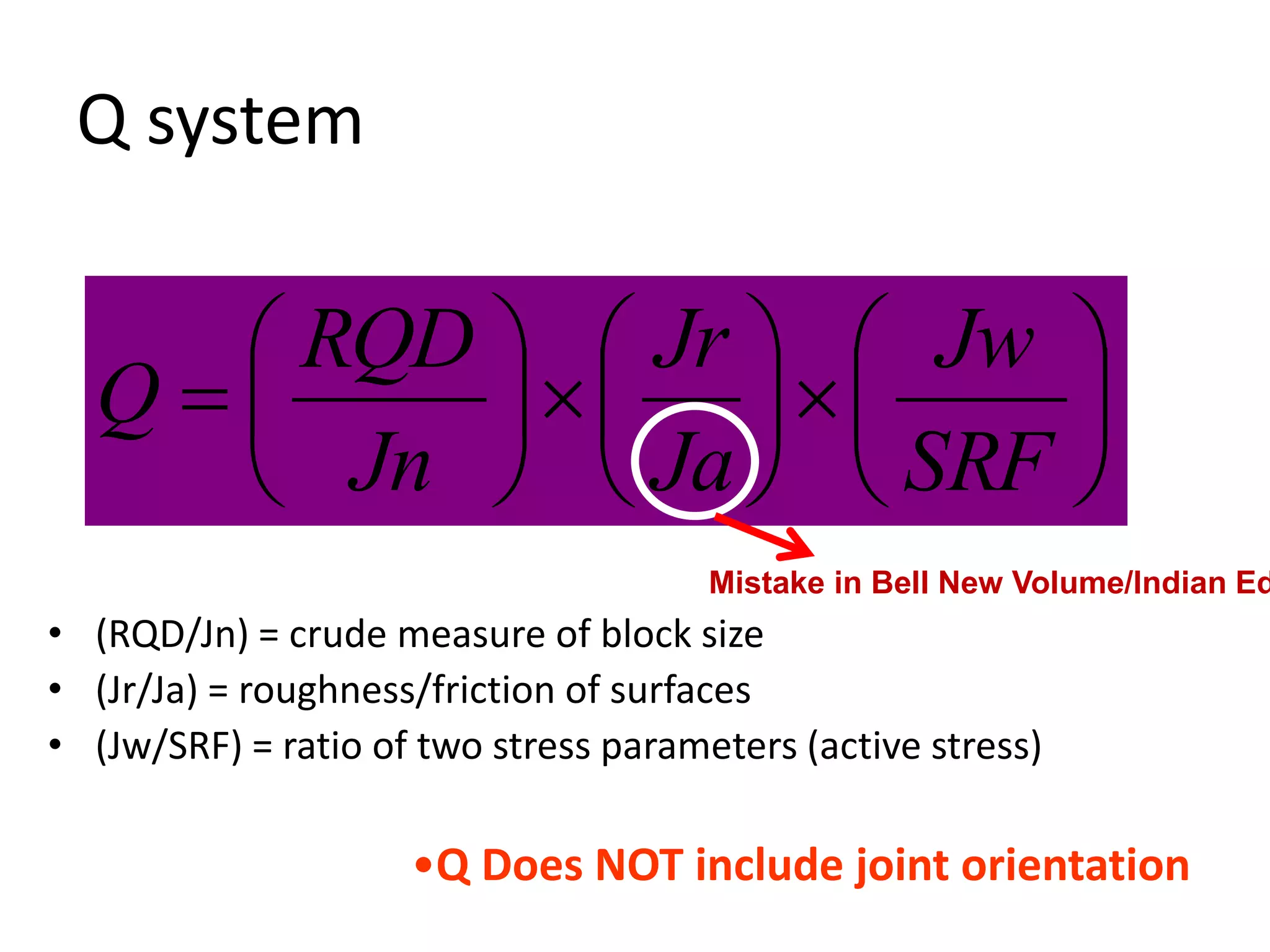

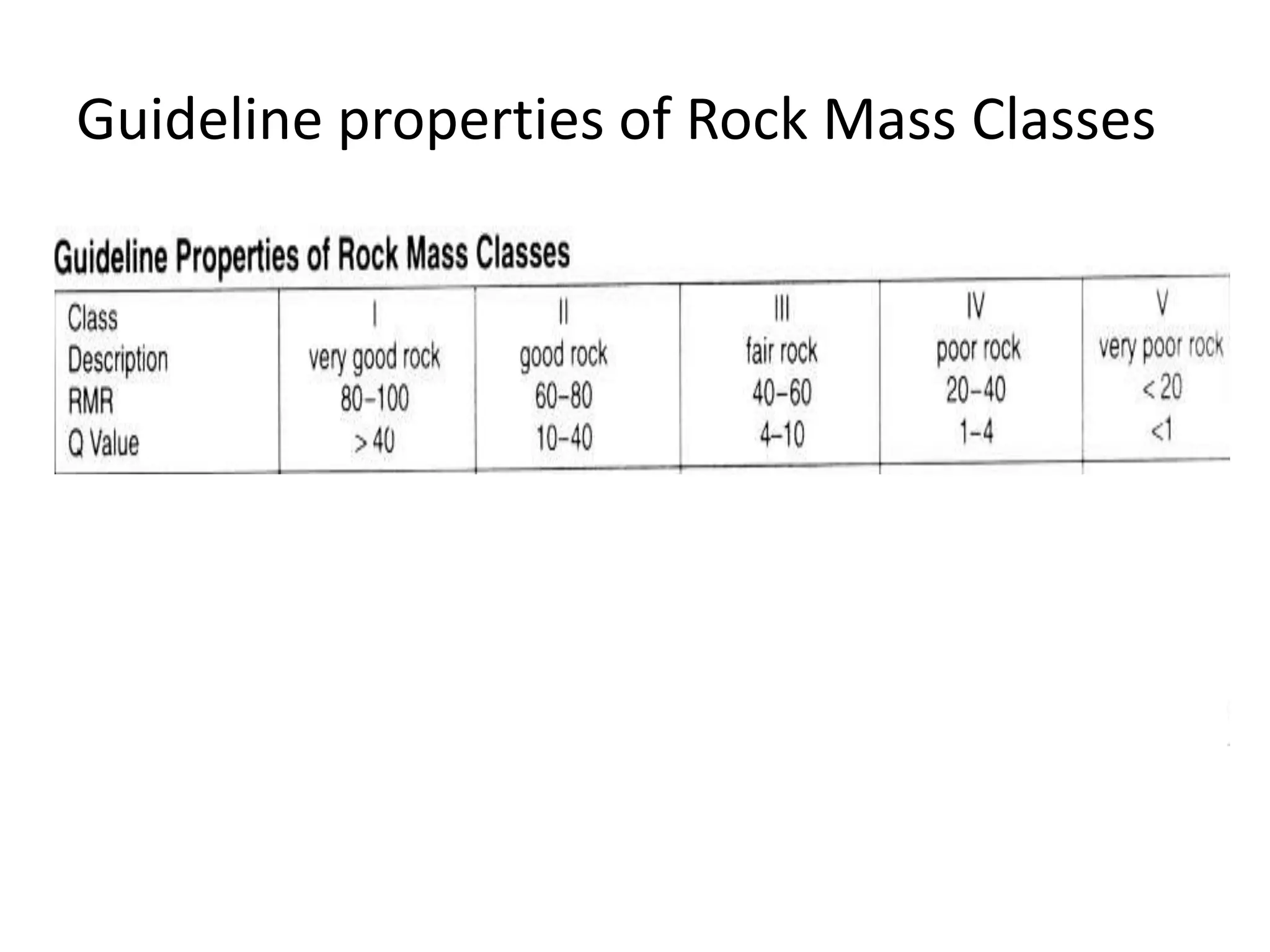

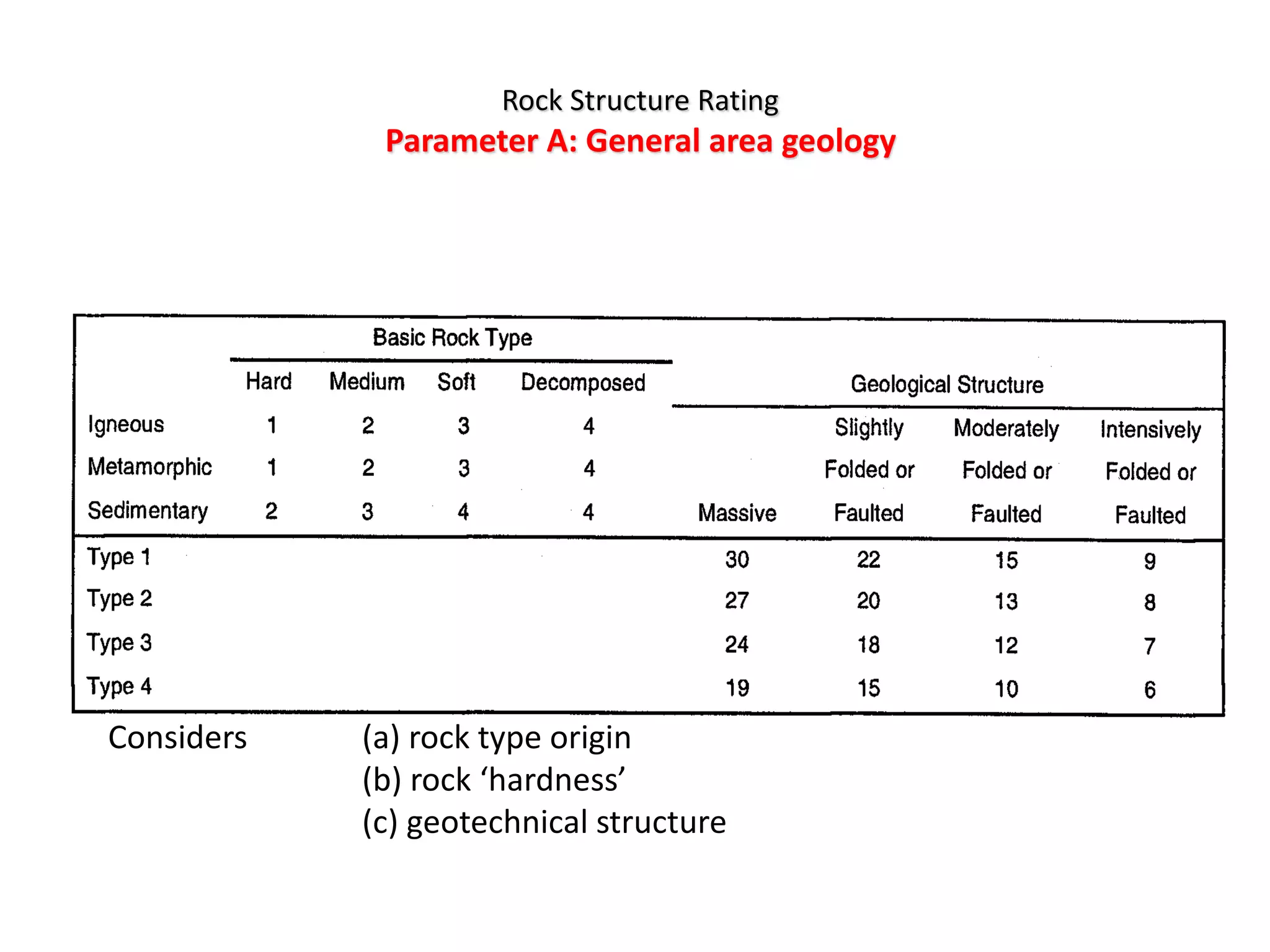

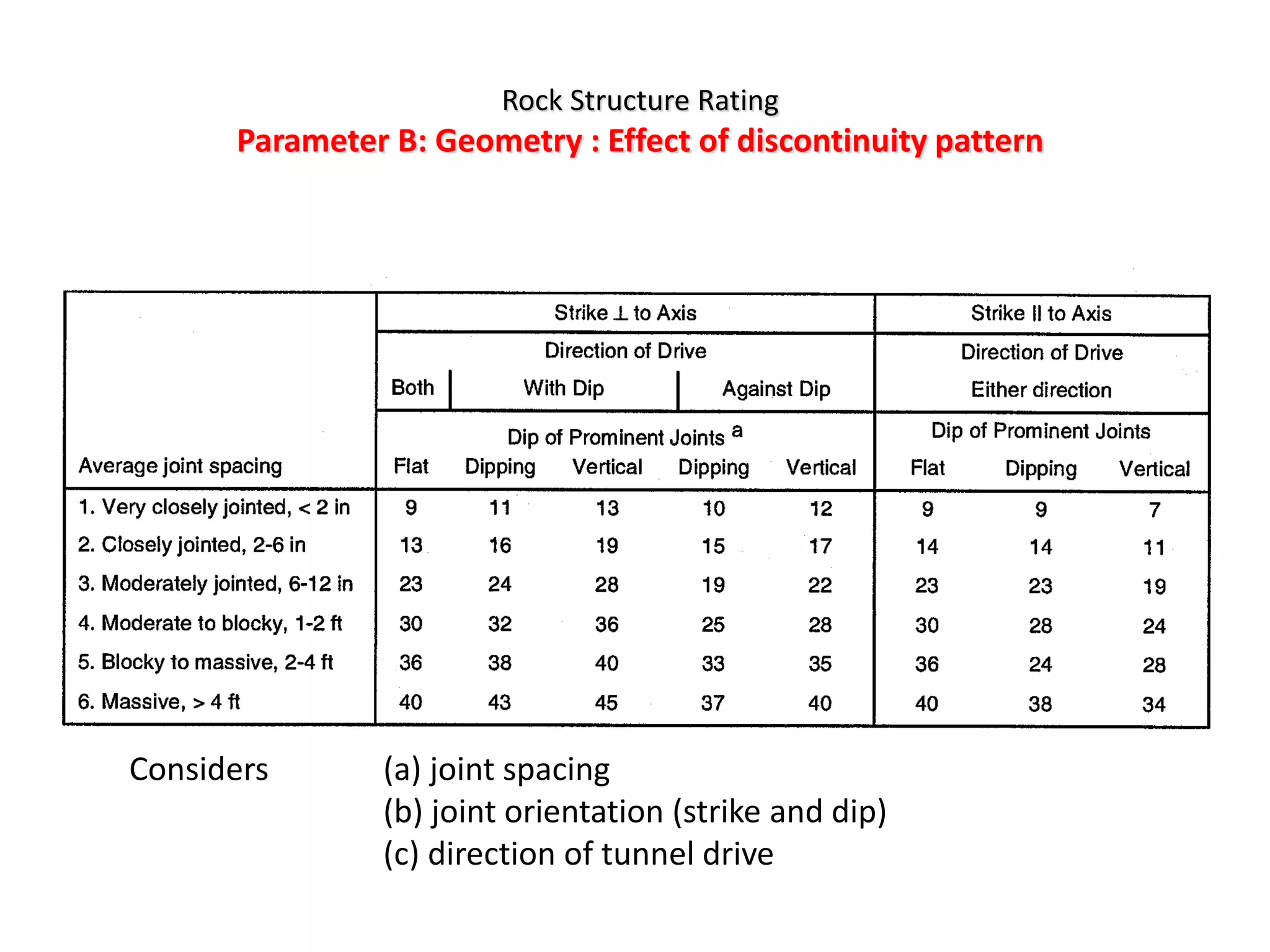

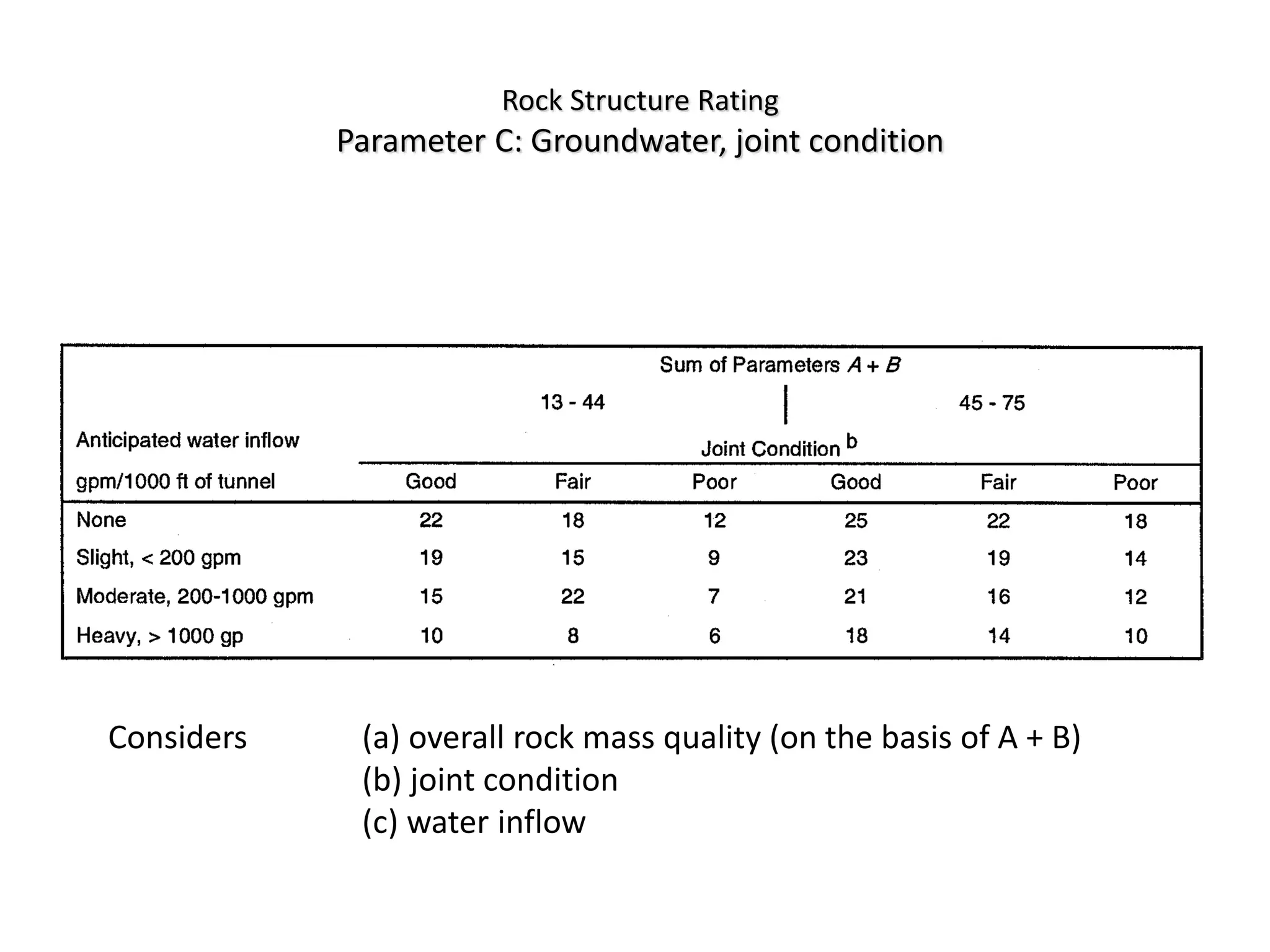

The document discusses various engineering classification systems that have been developed for classifying rock masses. It describes early systems developed by Terzaghi and Deere, which focused on weathering and discontinuities. It then explains more comprehensive classification schemes that consider additional parameters like strength, modulus, in-situ stresses, and water conditions. These include the Rock Mass Rating (RMR) system, Q-system, Rock Structure Rating, and others that assign numerical values based on ratings of different parameters for use in engineering projects.