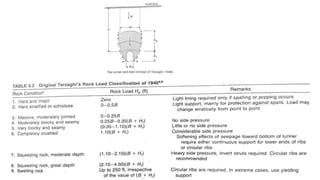

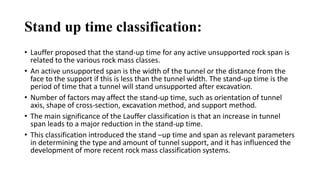

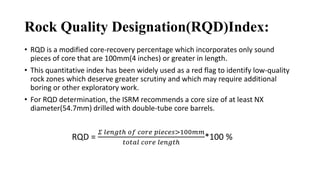

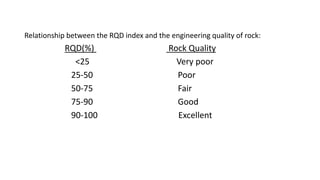

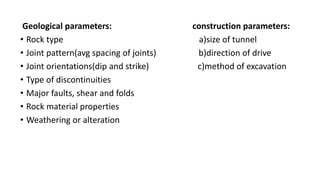

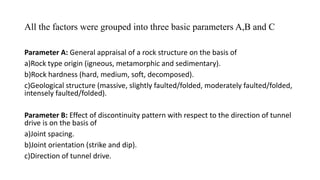

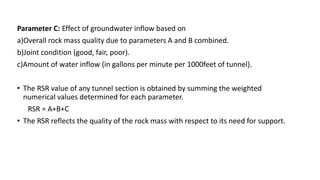

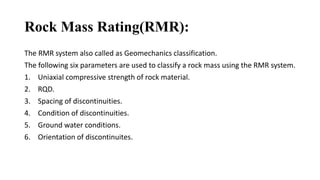

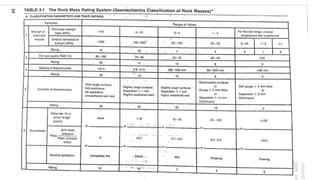

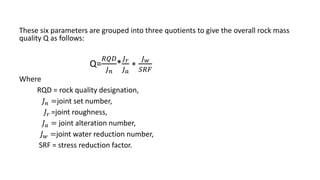

The document discusses various rock mass classification systems used in rock engineering. It describes the objectives and benefits of rock mass classification, which include identifying significant parameters that influence rock mass behavior, dividing rock masses into quality classes, providing quantitative design guidelines, and improving site investigations. Several historical classification systems are outlined, including the Rock Load Classification, Stand-Up Time Classification, RQD, RSR, RMR, and Q-System. Each system uses different parameters to evaluate rock mass quality based on factors like strength, discontinuities, water conditions and others. Rock mass classification provides an empirical design approach and common framework for communication between engineers and geologists.