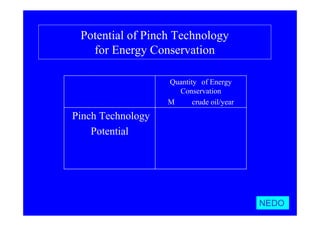

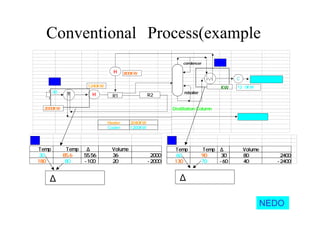

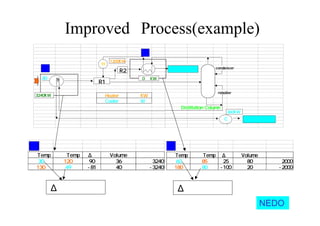

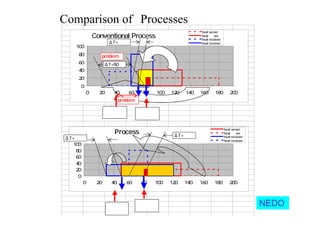

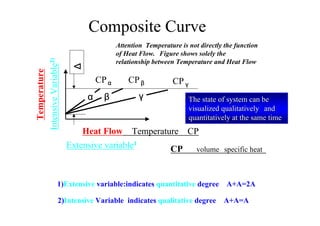

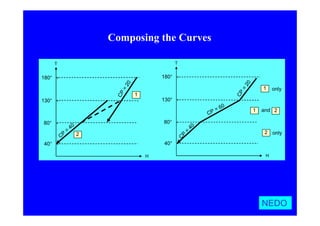

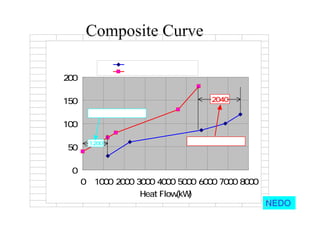

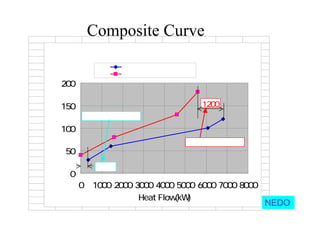

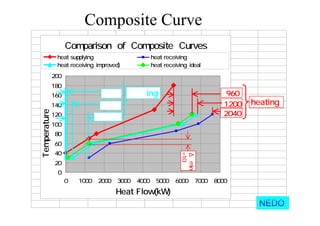

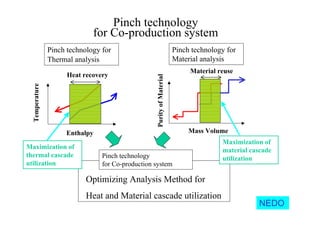

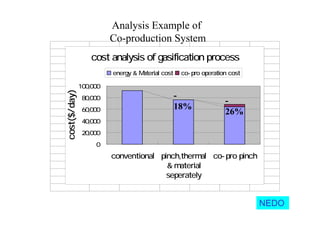

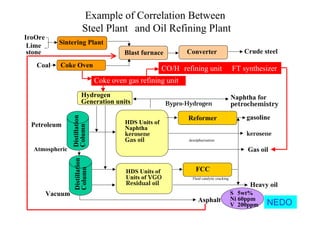

This document discusses pinch technology for energy conservation activities. It explains that pinch technology can visualize heat flow qualitatively and quantitatively through composite curves. Pinch technology has the potential to conserve over 500-1000 million liters of crude oil per year. Moreover, pinch technology applied to co-production systems can further increase energy conservation effects by maximizing thermal and material cascade utilization between different production processes.