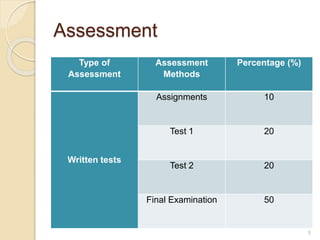

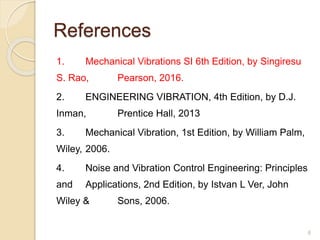

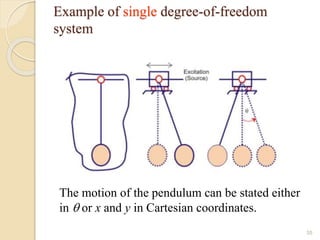

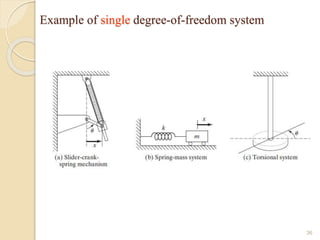

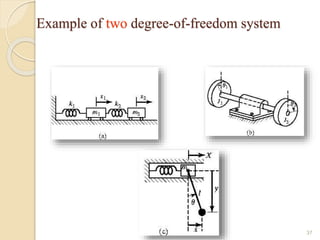

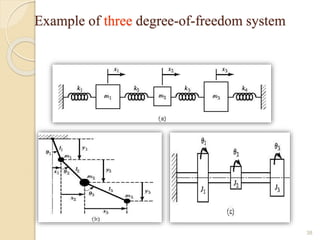

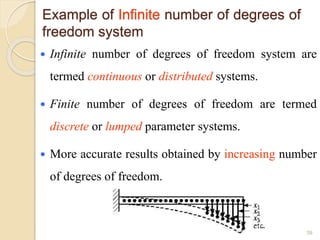

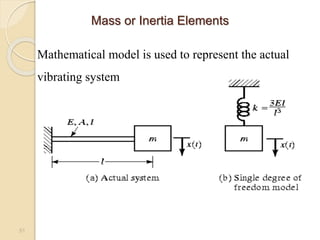

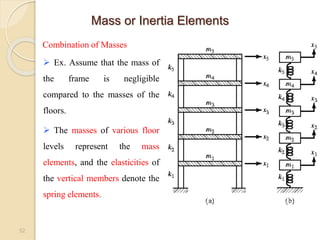

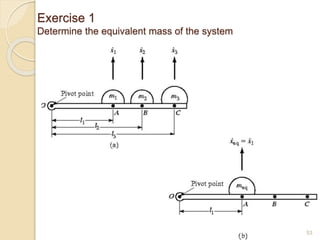

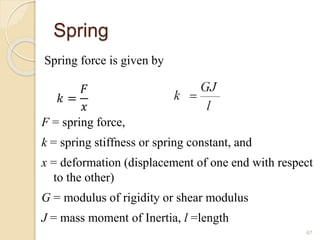

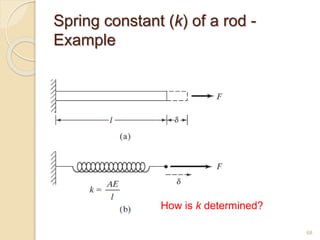

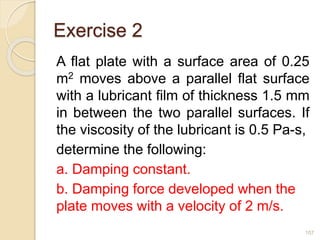

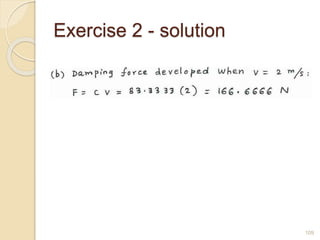

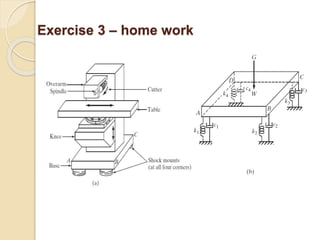

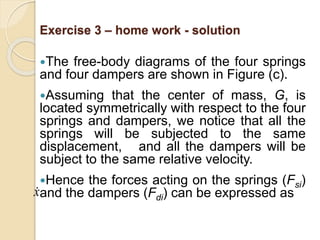

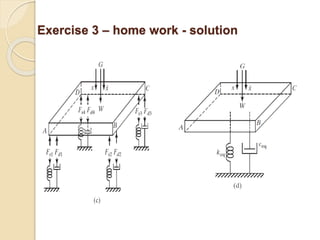

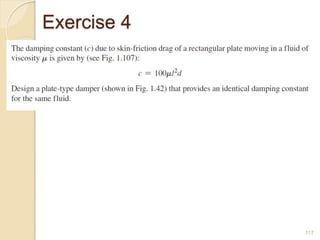

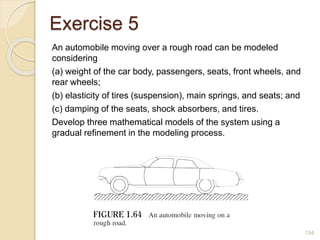

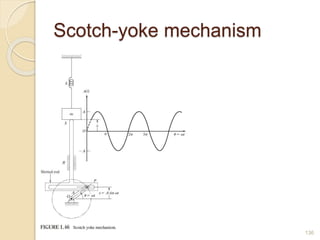

This document outlines a course on mechanical vibrations. It includes 5 course learning outcomes related to describing vibration principles, evaluating solutions for single and multi-degree of freedom vibration systems, and analyzing engineering implications of resonance. The course covers topics such as undamped and damped single-degree systems, forced vibrations, two-degree systems, and vibration resonance. Assessments include assignments, tests, and a final exam. References for the course are also provided.