The document outlines a tutorial on Electronic Document Management (EDM) systems intended for the process and manufacturing industries, emphasizing a strategic approach for implementation. It addresses the need for an EDM strategy to improve productivity by efficiently managing extensive documentation, which is often poorly integrated and difficult to access. The document serves as a roadmap for defining and deploying an EDM system within organizations, detailing its core components, applications, and technical requirements.

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 8

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

1.2. WHY AN EDM STRATEGY?

Strategies are intellectually simple; their execution is not.

[1]

The Electronic Document Management (EDM) Strategy is an implementation independent

system design framework, intended to provide the flexibility to assemble EDM software products

in a manner which best suits the business needs of the company, while providing access to

corporate documents and related data by all authorized users. These corporate documents

should be seen as data that is shared across the business processes. These documents are

valuable corporate resources and are not owned by one business unit or individual.

The EDM strategy promotes the interoperability

[2]

and operability

[3]

of software products that

consist of programs, transactions and databases. This strategy is not an architecture for these

programs, transitions and databases, but is a road map for providing the underlying solution.

[4]

1.3. SCOPE OF THE EDM STRATEGY

The scope of the EDM Strategy is usually defined during the initial engagement between the

technology providers and the technology users. The business units, which will be targets of the

EDM System, can be determined through a Business Case Analysis, which identifies the

financial benefits to the organization of each document automation activity.

Within these business organizations, controlled documents are usually generated, used, and

stored by the following departments:

(a) Engineering – product design documentation, facilities to manufacture products

and the infrastructure to support the manufacturing facilities.

(b) Research and Development (Technical Documents) – documents that describe the

prototypes of products, the procedures for constructing thee prototypes and the

design basis calculations used to develop the prototype.

(c) Maintenance – equipment and process support instructions.

(d) Environmental Controls and/or Regulatory Compliance – materials used in the

process are accounted for and described according to the guidelines of the

regulatory agencies.

(e) Records Management – maintenance, production, parametric data, material

quantities all have record information associated with individual documents.

(f) Office Technology – process correspondence, management information, corporate

policies, customer correspondence.

1

“The CEO as Coach: An interview with AlliedSignal’s Lawrence A. Bossidy”, N. M. Tichy and R.

Charan, Harvard Business Review, March–April, 1994, pp. 68–78.

2

Interoperability is the ability to connect document aware software products irrespective of their

suppliers or vintage, to provide access to corporate documentation.

3

Operability is the ability to efficiently and cost effectively manage and control the deployment,

administration, execution and use access to a loosely coupled set of software products,

irrespective of the suppliers to meet the performance, availability, reliability and security

objectives of business organization.

4

“The BellCore OSCA Architecture,” Technical Advisory, TA–STS–000915, Issue 3, March 1992.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-8-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 9

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

The following departments, business units, and activities are usually not addressed by the EDM

Strategy:

(g) Documents and activities involved in the business data processing.

(h) Documents not considered controlled information.

1.4. PURPOSE OF THE EDM STRATEGY

This document defines the vision of an Electronic Document Management system to be

employed throughout the business organization. The EDM System will provide for the electronic

management of corporate documents in conjunction with existing business data processing

systems.

This document is not meant to be an all inclusive description of an EDM system, rather it is the

road map for defining an actual EDM system and deploying it within the business organization.

This document is written as a high level description of the EDM system, its initial benefits, and

costs. Beyond this EDM Strategy are several other documents that are usually produced during

an EDM project including: System Requirements Analysis (SRA), Functional Requirements

Analysis (FRA) and Technical System Design (TSD), Implementation Plan (IP), Procurement

and Installation Plan (PIP).

This document contains several sections, including:

(a) Core Business Strategy – which describes the motivations for the EDM system,

the architectural vision of deployed system.

(b) Attributes of an EDM System – which describes the hardware and software

components of an EDM system and its application to the various business

organizations.

(c) Core Information Technology Strategy – which describes the technology, required

to deploy an EDM system in the business environment.

(d) Identified Strategic Applications – which describes the target business

organizations to receive EDM.

1.5. DEFINING THE EDM STRATEGY

In order to formulate a strategy for the deployment of an EDM system, two dimensions must be

considered:

[5]

(a) Breadth – the scope of applications, processes, or systems that will be addressed

by the EDM strategy must be defined. A process can be defined as narrow as a

single activity or single function or as broad as the entire business. The EDM

strategy addresses specific processes within specific business units.

The management of controlled documents is most often the breadth of the EDM

system.

(b) Depth – the success of the EDM strategy, on a broad scale, requires the

restructuring of the key business components. The measure of the depth of the

strategy can be characterized by the amount of:

(1) roles and responsibilities of the management in the effected organizations;

(2) the affect on the information technology infrastructure;

5

“How to Make Reengineering Really Work,” G. Hall, J. Rosenthal and J. Wade, Harvard

Business Review, November–December, 1993, pp. 119–131.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-9-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 11

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

business process applications built around a client/server topology using open

application interfaces.

[6]

(b) Document Management is ... a software system that is capable of organizing

document production, managing accessibility and distribution of documents and

overseeing the flow of these documents.

[7]

The I/S EDM strategy is to:

(a) Provide the underlying infrastructure of the networking and platform facilities

required for the EDM system.

(b) Provide the architectural guidance for the selection and installation of the software

applications required for the EDM system.

(c) Provide the necessary resources to support the infrastructure and related computing

resources needed to deliver the EDM system requirements to the end user

community. This includes:

(1) Data modeling of the business process.

(2) Process modeling of the business process.

(3) Definition and support of document management standards for those

components of the EDM system that are shared throughout the business

organization.

(4) Support and maintenance of the client/server components shared by all

users of the EDM system.

1.8. CRITICAL SUCCESS FACTORS FOR THE EDM SYSTEM

The concept of Critical Success Factors (CSF) Analysis was first formulated by John Rockart at

MIT in the 1982.

[8]

The main steps of the CSF are:

(a) Identify the most critical components, facilities and processes of the enterprise,

which will make the enterprise successful.

(b) Define the application systems, business data and business rules for each business

process, which will support the critical success factors.

(c) Analyze, evaluate, and justify the proposed application systems.

An Electronic Document Management System can provide for the creation, control, and

distribution of almost any form or type of document. The question is what types of documents

should be managed inside business organization?

6

Office Information Systems Strategic Analysis Report, The Gartner Group, September 3, 1993.

7

“Workgroup Application Systems,” Document Management Software market Review and

Forecast, International Data Corporation, May, 1993.

8

“The Changing Role of the Information Systems Executive: A Critical Success Factors

Perspective,” J. Rockart, Sloan Management Review, Volume 24, Number 1, 1982, pp. 3–13.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-11-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 12

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

This focus is best stated as...

A business can be made more valuable by making low intellectual content

activities effortless and high intellectual content activities more functional and

available to knowledge workers at every level... if an organization has not

eliminated clerical office activities almost entirely from job descriptions, it will

suffer from poor customer service, poor use of its information assets, longer

times to market and higher operating costs.

[9]

1.8.1. Critical Success Factors for Manufacturing and Process Industries

The Critical Success Factors for the EDM system deployed in manufacturing and process

industries include:

(a) Reduction of cycle time for work activities involving the production, handling,

distribution, and use of paper–based documents and drawings.

[10]

(b) Simplification of the paper–based work processes associated with the production of

products, the design of the manufacturing process and the support of the installed

process or manufacturing equipment.

(c) Reduction of plant downtime by making the necessary engineering, operations and

maintenance documentation available on–line and readily available to the

appropriate maintenance and operations personnel.

(d) Reduction or elimination of the cost associated with paper–based processes,

including copying and filming of documents for distribution and reference. This

reduction will be applied across the board for all controlled paper–based processes.

(e) Improved document security since the document images are never removed from

storage.

(f) Establishment of stable procedures associated with the manufacturing process,

including standard operating procedures, work instructions and any associated

operational documentation.

(g) Improved quality for all documents resulting from the audit, change control and work

flow automation capabilities of the system. These facilities will provide a reduction in

the content, reproduction, and distribution processes. The use of outdated

information is reduced when all users are ensured access to the same revision of the

document.

(h) Decreased cost for modifying documents, since all documentation is available on–

line there is no need to re–create the document when it can not be found.

(i) Integration with maintenance and production management system. By delivering

images of maintenance manuals and supporting documents, the existing paper–

based system for the distribution and maintenance of equipment documentation can

be replaced.

(j) Establishment of a networking system capable of supporting the EDM system. This

includes providing document management cache servers connected to segments of

the network without impacting other portions or the enterprise. On demand printing

provides a point if use for the correct documentation. Work procedures, maintenance

9

Office Information Systems Strategic Analysis Report, The Gartner Group, September 3, 1993.

10

Throughout this specification, the term document shall be taken to mean documents and

drawings.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-12-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 14

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

(3) Islands of document automation usually exist, making it difficult to assemble

information. The isolation of the information generating activity creates the

opportunity to release documents with inaccurate or incomplete information.

(4) The ability to find accurate and timely information is restricted by the

computing infrastructure in place today.

(b) Improved Quality – by managing the production, review, and distribution of all

controlled documents, the quality of documentation process can be improved.

(c) Lower Costs – by removing unnecessary activities from the daily business process,

the cost of production can be lowered. By improving the accuracy and velocity of

information available to the organization’s employees, the amount of productive

work per hour invested will improve.

(d) Establishing a Design Basis – by capturing and indexing engineering, production and

maintenance information, the foundation of the design and operation of the product

production processes can be communicated to both internal and external

organizations, in a concise, reliable and controlled manner.

1.8.3. Common Business Activities

The success of an EDM deployment at the business depends on several factors, including:

(a) A common desktop environment and architecture.

(b) On–line access to applications and information needed to perform work without the

knowledge of the information location.

(c) A standardized and easy to operate User Interface.

11

(d) The availability of personnel productivity tools.

(e) The automation and reduction of paperwork associated with each business activity.

(f) Integrated analysis and design applications in Engineering (or Technical Functions).

(g) A common set of work management tools which form the basis of information

sharing, including E–Mail, document viewing, printing, work flow, and authoring

tools.

1.8.4. Common I/S Functions

The EDM strategy is based on the use of open platforms for all hardware and software

components of the system. For the purposes of a strategic plan the following definition will be

used:

An open system is one in which the components (of the system) and their

composition are specified in a non–proprietary environment, enabling competing

vendors (of the system components) to use those standard components to build

cooperative systems.

[12]

Using this definition, the functionality provided by I/S in support of the EDM system must include:

11

The specification of attributes of the system using terms such as easy to operate, User

friendly, high performance, reliable, should be avoided at all times. The attributes of the system

should be specified in quantitative terms, which have specific measures, which can be used to

compare the various alternatives. Although this advice is given for writers of requirements

specifications, there will be many instances in this tutorial where the advice is not followed.

12

Open Systems, G. Nutt, Prentice–Hall, 1992.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-14-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 15

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

(a) Hardware platform independence for applications and databases – the flexibility to

use the most cost–effective platform for the job will allow the business organization

to take advantage of an ever changing hardware market place, without a negative

impact on the current investment in software, training and data.

(b) Application independence from databases – by making use of SQL access to

information the underlying database technology can change over time with a

minimum impact on both the application and data environment.

(c) Distribution of information and applications as close as possible to the users – by

making information locally available to the end user, query and retrieval time

required is reduced to a minimum.

(d) Consolidating and normalizing information to eliminate redundancy and improve

data integrity. By constructing normalized data models with embedded business

rules, the intellectual value of the document relationships and the transactions that

created them can be maintained over the live of the project.

1.8.5. Existing I/S Strategic Investments

Several existing I/S strategic investments are associated with the success of the EDM system,

including:

(a) Financial Systems – the Business Reporting System, forms the basis of the benefit

measurement for EDM.

(b) Telecommunications Infrastructure – the existing network infrastructure must

adapt to the requirements of the EDM System. The architecture of the

telecommunications system hardware and software forms ground work for the

EDM system client/server architecture.

(c) Document Authoring Infrastructure – the existing CAD, Word processing and

Email environment provides direct support for the EDM project.

1.9. END USER EDM VISION

A Vision is a picture in ones mind of an idea or organization. A vision is an essential element in

the success of an organization. This section describes the vision of the EDM system, distinct

from the Mission of the EDM system.

[13]

These differences can be illustrated as:

Mission Statement Vision Statement

Today Tomorrow

Identifies the customer(s) Inspirational

Identifies the Critical Processes Provides clear decision–making criteria

Level of performance Timeless

Although they are often used interchangeably, mission and vision are distinctly different, each

with its own purpose, style, criteria and components. A vision is a state that is never achieved,

13

“Visioning: The Concept, Trilogy and Process,” J. R. Latham, Quality Progress, American

Society for Quality Control, April, 1995, pp. 65–70.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-15-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 16

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

but will form the basis of all activities within the organization. Successful visions have three (3)

criteria:

[14]

(a) Timeless – visions are far reaching, they describe the corporation or system, as it

should be, not necessarily as it is going to be. It is unlikely that the vision of the EDM

system will ever be achieved, but articulating the vision will set the highest possible

goal for the system. All decisions regarding architecture, behavior and performance

of the system should be compared with the vision of the system. Progressive

realization of the vision is critical to the success of the overall process.

(b) Inspirational – it is inspiration that is behind the motivation to act. It is action toward

the vision that ultimately makes the vision a reality.

(c) Provides Clear Guidelines – a clear, concise and shared picture of the end result

provides the criteria for the decision making process. When the vision of the EDM

system is shared among all members of the business organization, the tactical

details of the implementation of the system become secondary to the overriding

goals of the organization. Everything is created twice: first in the mind, then in the

physical world.

[15]

The Vision for the EDM system in the manufacturing and process industries is that it will provide

the foundation for re–engineering the business processes in the following departments:

(a) Engineering – by significantly reducing the generation, handling, and consumption of

paper documents during the design, review, and construction process. By deploying

the EDM System, Engineering will be able to eliminate the storage and distribution

costs currently associated with the document release cycle.

(b) Research & Development – by consolidating the authoring, review and publication of

Specifications, Standards and Work Instructions, R&D can eliminate all redundant

operations in deploying these documents to the users.

(c) Maintenance – by providing electronic access to all equipment documentation,

Maintenance can eliminate all wasted effort currently expended in the search for

maintenance information and work instructions.

(d) Records Management – by consolidating the management of corporate records with

the control of the source documents referenced by these records, the EDM system

will consolidate two functions into one. The management of the controlled

information is usually provided separately from the physical storage and use of the

controlled documents. These functions could be consolidated inside the EDM

system, with the indexing and management controlled by a database application and

the physical capture, use and distribution provided by the facilities of the EDM

system.

(e) Office Technology – by providing electronic images of business records document

storage and distribution activities can be significantly reduced with an equivalent

reduction in this recurring expense. The capture, indexing, storage, and distribution

of business documents are a traditional application for an EDM system. A scanning

and indexing operation can replace the current microfilming and indexing (to the

mainframe) operation. Once scanned the documents can be delivered to the end

user through a workstation application, completely eliminating the need for microfilm

production, storage and distribution.

14

Teaching the Elephant to Dance, J. A Belasco, Crown Publishers, 1990.

15

The 7 Habits of Highly Effective People, S. R. Covey, Simon & Shuster, 1989.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-16-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 18

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

(3) The local alterations or additions to the discipline–specific standards.

(e) A collection of design basis calculations, notes, and supporting documentation

created during the design and construction process. This information will be

maintained by the EDM system for reference during future design activities as well

as form the basis of the intellectual contribution of the Engineering department to the

operation of business organization.

(f) Software created and used by the various production test or process control

systems. This software will be stored as an object in the EDM – as if it were an

electronic document. The indexing, submittal, retrieval, and use of this software will

take place in the same manner as normal user–readable documentation.

(g) Information used by the Engineering modeling applications can originate as well as

be stored by the EDM system. This information includes:

(1) Design calculations.

(2) Data and programs for modeling the plant processes.

(3) Parametric information gathered from various sampling and control system

can be placed in the EDM system as electronic representations of data. This

information can then be forwarded to the modeling software for processing.

1.9.2. Quality Assurance EDM Vision

The management of documents in the Quality Assurance department is a critical business

function.

These document classes include,

(a) Specifications for recipes, formulas, processes, work instructions, test programs, etc.

(b) Test methods for each process.

(c) Organizational policies and procedures.

(d) QA reports, including:

(1) Test reports

(2) Quality reports

(3) Test plans

(e) Other documentation including:

(1) Defect manuals.

(2) Hand books.

Each of these document classes forms the basis of the Quality Assurance process. Most

document management activities currently taking place in the QA department follow industry

guidelines

[16]

developed and implemented in a variety of production environments:

(a) Management Responsibility: ... define, document and communicate its policy and

objectives for, and commitment to, quality; appoint management representatives for

periodic review to ensure continuing suitability of the quality system. The supplier

shall ensure the policy is understood, implemented, and maintained at all levels in

the organization.

16

“Vision 2000: The Strategy for the ISO 9000 Series Standards in the 90’s,” D. Marquardt, et

al., ASQC Quality Progress, Vol. 24, No. 5, May 1991, pp. 25–31.; “Management Practices: U. S.

Companies Improve Performance Through Quality Efforts,” General Accounting Office,

GAO/NSIAD–91–190, May, 1991.; “Fix the Process not the Problem,” H. Sirkin and G. Stalk,

Harvard Business Review, July/August 1990, pp. 26–33.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-18-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 19

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

(b) Quality System: ... establish a documented quality system as a means of ensuring

that it conforms to the criteria of the applicable...standards.

(c) Design Control: ... establish and maintain procedures to control and verify the

product design in order to ensure that the specified requirements are met and assure

procedures for design planning and design changes are in place.

(d) Document Control: ... establish and maintain procedures for controlling all

documents and data thorough approval, distribution, and modification that relate to

the requirements of the Standard... The documents shall be reviewed and approved

for adequacy by authorized personnel prior to use.

(e) Product Identification: ... establish and maintain procedures for identifying the

product from applicable drawings, specifications, or other documents, during all

stages of production, delivery and installation...

(f) Process Control: ... shall identify and plan production and ... ensure that these

processes are carried out under controlled conditions ... Documented process control

instructions defining the manner of production ... where the absence of such

instructions would adversely affect quality.

The EDM system will provide the following functions for the Technical Document activities in the

QA Department:

[17]

(a) Authoring – the EDM system will provide a controlled process for creating and

altering documents. The generation and editing of text and graphical documents is

performed using standard workstation tools. Today these tools include word

processors and graphical design applications. The results of the authoring processes

will be maintained by the EDM system in the Electronic Vault.

The creation of a document will start with the creation of an entry in the Electronic

Vault’s index. This index entry will be used to reference the document through out its

life.

If an existing document is to be used as the basis of a new document or simply a

revision, then the original document is checked–out of the Electronic Vault for

revision. Changes are then made to the document and it, like the previous example

is checked–in to the Electronic Vault for review and promotion.

(b) Review and Promotion – the EDM system will provide the ability to mark up the

review copy to indicate any changes or suggestions. Once the changes (or creation)

have been made to the document, it will be reviewed for promotion to the next

release level. This activity will take place using the tools of the EDM system. Using

electronic mail or a vendor–provided workflow system notification that changes exist

and require review will be forwarded to the appropriate distribution list.

(c) Publication – the EDM system will provide for consistent publication and distribution

of the controlled documents. The approved documents will be placed in the

Electronic Vault as an official release. The release of the document will replace the

previous release and notify those on the distribution list of the existence of the new

document.

(d) Retrieval, Viewing and Printing– the EDM system will provide a consistent process

for retrieving and viewing controlled documents. The retrieval and viewing of the

document will take place through the facilities of the Electronic Vault. The data

model that defines the business rules for managing the documents will form the

17

In general, these steps of Authoring, Review and Promotion, Publication, Retrieve, Viewing

and Printing can be applied to all document management functions.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-19-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 20

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

basis of the retrieval process. This data model defines the relationships and

attributes of the documents and the processes by which changes are made to the

documents.

The viewing of the document will take place by rendering the image of the

document in a form identical to the creation of the document, without the burden of

placing the authoring tools on each workstation. The viewed document will contain

text and graphics as well as images. Comments and notes can be made on the

viewed document and returned to the author for action.

Those users not involved in the authoring and review processes will be provided

with the ability to view the documents, but not the ability to make changes to the

controlled document, other than as suggestions to the author.

1.9.3. Maintenance EDM Vision

It could be argued that operations and maintenance is a secondary function in the US, when

compared to the dominant technical disciplines of development and manufacturing.

[18]

Although this may not always be the case at all businesses, there are usually several underlying

difficulties with the current maintenance and operation of process or manufacturing facilities

directly related to the management of documents:

(a) Proactive maintenance – the largest expenditure for maintenance today occurs in

the area of corrective maintenance. The major contributor to the unit operating cost

of the plant equipment is the cost to restore this equipment to operation coupled with

the cost of lost production.

(b) Maintenance work – by decreasing the number of human mistakes that occur during

the normal course of maintenance the overall cost of operating the process or

manufacturing facility can be reduced.

(c) Standard documentation and information not available – by increasing the

availability and accuracy of the information used during the maintenance process,

the overall maintenance cost can be reduced.

By addressing these issues through the deployment of an EDM system, the maintenance of the

production facilities can be improved. Documentation enters into this improvement in the

following manner:

(d) Task Specifications – by defining what actions need to be taken and when they need

to be performed, the maintenance of the equipment can be improved. The OEM of

production equipment usually provides the documentation containing this

information. Access to these documents takes place through a manual process.

(e) Procedure Specifications – this is a document which guides the execution of the

maintenance task. In simple situations, the procedures may be as simple as a one–

page instruction. In more complex tasks, a maintenance manual must be referenced

in order to proceed with the procedure.

(f) Logistics – this activity entails a variety of activities ranging from purchasing, stores

management, tooling, vendor support, training and regulatory requirements. Each of

these activities involves the use, creation and distribution of documents.

1.9.4. Records Management EDM Vision

The management of official records usually takes place through several databases. The actual

documents recorded in these databases are physically held by different organizations.

18

Reliability–Centered Maintenance, A. M. Smith, McGraw–Hill, 1993.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-20-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 23

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

2. EDM BACKGROUND, TERMINOLOGY AND TECHNICAL ARCHITECTURE

This section provides a background overview of the use of Electronic Document Management in

the industrial setting. By restricting the target application environment to process plants,

manufacturing facilities or electric utilities, a class of technical issues found in the traditional

business office environment can be avoided. The technical document environment creates a

unique set of requirements:

(a) Large document sizes with accompanying impacts on system performance.

(b) The use of formal management of change processes.

(c) Tight integration of the EDM System with CAD, MRP, ERP, production and

process control systems.

(d) Regulatory compliance (ISO, OSHA, EPA, FDA)

(e) Subcontractor management of supplied components, services or facilities.

2.1. PHILOSOPHICAL GOAL OF AN INDUSTRIAL EDM SYSTEM

In order to create a clear and concise picture of the requirements for the EDM System, a

philosophical goal is needed.

[19]

This goal is:

Gather the information needed to design, construct, operate, and maintain the

business’s facilities in a single coherent, secure and accessible Electronic

Document Management System.

The operational definition

[20]

of the terms in the goal are:

(f) Design – is the process of creating a solution to a problem using engineering,

technical writing or related skills?

(g) Construct – is the process of providing the solution in its physical form?

(h) Operate – is the process of placing the physical equipment or material into

operation?

(i) Maintain – is the process of keeping the physical equipment in operation?

(j) Coherent – is a logically correct and understandable set of rules for using the

system?

(k) Secure – is the ability to provide information within the proper context?

(l) Accessible – is an easily approachable and understandable interface for document

retrieval?

2.2. MOTIVATIONS FOR EDM AT A PROCESS OR MANUFACTURING FACILITY

A process or manufacturing facility creates and uses from hundreds of thousands to several

million pages of documentation during the course of its business every year. The majority of

19

The World of Edwards Deming, 2nd Edition, C. S. Kilian, SPC Press, 1992.

20

An operational definition assigns a communicable meaning to a concept and specifies the

conditions and procedures for ascertaining whether it applies in a given condition. Without an

operational definition the terms are meaningless concepts that hamper communication. “How to

Distinguish Masters from Hacks,” K. T. Delavigne, Quality Progress, May, 1995, pp. 97–102.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-23-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 28

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

(3) A direct query approach in which the user posses a query for a document or

set of documents and is presented with the match list of documents that

correspond to the requested query.

In all cases the retrieval of documents is performed through the appropriate data

model. The use of arbitrary keywords and phrases attached to the documents

should be avoided.

[21]

Once the document has been retrieved to the users

workstation, markups can be applied to the document and returned to the

originator. These markups can be as simple as a sticky note or as complex as

raster drafting suggestions to the drawings. In all cases the markups do not alter

the original documents and are controlled through the Management of Change

application residing in the EDM System.

(e) Document Printing – documents placed in the EDM System can be printed using

any of the printing devices attached to the network. In addition production printing

can take place using high volume printing devices. Documents can be selected for

printing in several ways:

(1) Once a document has been delivered to the user workstation, all or portions

of the document can be sent to a printer.

(2) A list of documents can be selected for printing, without retrieving them to

the workstation, but can be printed by the EDM System’s print server.

The printed documents can be marked with a variety of overlays to indicate

additional information, including:

(3) Date and time of printing.

(4) Gray scale bands placed over the document page to indicate usage and

security information.

(f) Management of Change – There are both regulatory as well as good business

practice requirements for managing the change to the documents captured by the

EDM System. The Management of Change application will:

21

The use of Full Text Search (FTS) or Content Based Retrieval (CBR) as the primary indexing

method presents several problems. The management of a document index requires that the user

have confidence that the proper document or documents have been delivered to the workstation.

The CBR method makes use of a statistical matching approach, either by calculating the

probability that a set of words match the retrieval key or some other probabilistic method of

matching patterns. However, the documents stored in the EDM system and delivered to the

production floor have specific and deterministic indexing information associated with them.

When an operator requires a document, there is not a probabilistic request for documents that

might match the request. The operator will be delivered the proper document with 100%

assurance that it is the correct document, the proper revision and the appropriate document for

the situation. This retrieval method is provided through a data model that defines the business

rules for the delivery of documents. This situation requires deterministic searching and selection

of documents. Therefore the FTS or CBT method will not be provided for R&D documents

delivered to the production floor.

There are cases where the actual content of a document can be of interest to the user. This case

is where some type of research is taking place and the user does not know what documents need

to be located before the search takes place. This type of document management is usually found

in library applications. There are many complexities involved in deploying a FTS system that are

beyond the requirements of the normal business activity and management of Technical

Documents. For an in depth background on this issue see, “Rich Interaction in the Digital

Library”, R. Rao, et. al., Communications of the ACM, Volume 38., Number 4., April, 1995. Pp.

29–39.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-28-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 36

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

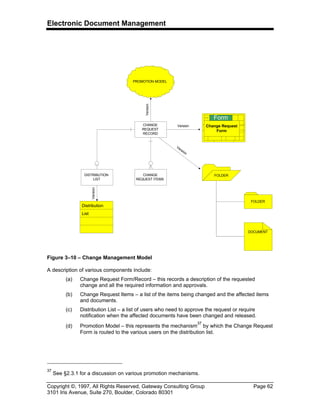

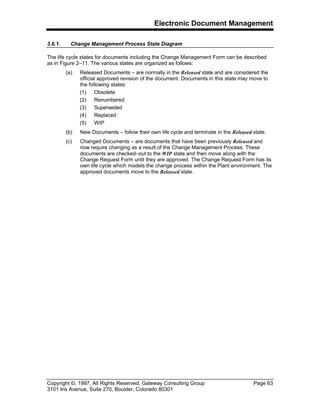

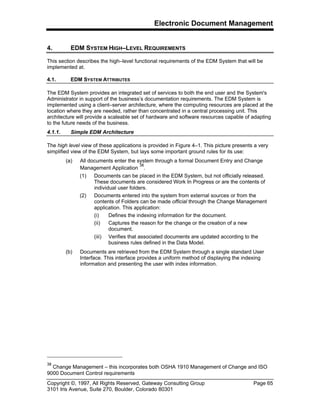

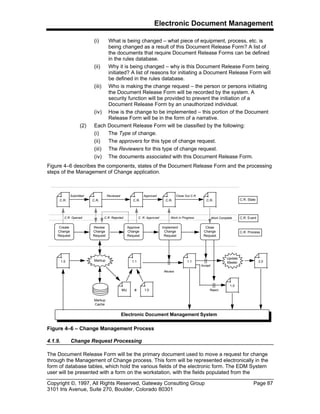

The following section describes the individual states of the process of managing documents

[22]

as shown in the previous figure:

(a) Start Drawing Process – this is the initial entry point into the system. When the

user wants to create a new drawing, the existence of the drawing is Reserved by

the system. The EDM System issues a place holder for the drawing, with the

attributes of the drawing type assigned to the default values. The creation of the

drawing usually takes place within the CAD system using the drawing number

assigned by the Drawing Registry. This drawing number is often placed in the CAD

file’s title block using the programmatic tools of the CAD environment

(b) Reserved – this is the state that reserved a drawing identifier for future use. When

drawings are being created, not all drawing numbers are known nor is it possible to

know the total number of drawings that will be produced. The EDM System usually

provides the ability to Reserve a drawing number or a range of numbers for use. If

the drawing numbers are not used they will be returned to the system for reuse.

(c) Registered – Once a new document is ready for release the document identifier

can be Registered with the EDM system. The document is registered through the

Document Entry and Change Management applications. At these points the new

document is presented to the EDM System and the indexing information provided.

(d) Pending Approval – A Change Management application is typically used to

update the Business Model Index. Prior to the entry of the document into the EDM

System and its official release, the document will have the status of Pending

Approval. This will allow documents to be placed in the EDM System and made

accessible to others, without requiring that they be officially released. When the

document is retrieved, viewed and printed, some form of marking is applied to

indicate that it is not the official release, but rather Pending Release.

(e) Approved for Check–In – This state is short lived and is assigned to the document

after it has been approved but before it is actually checked–in to the EDM System.

(f) Hold Drawing – when the document approval and check–in process has been

suspended for some reason (project is put on hold), the document can be placed in

the Hold state.

(g) Renumbered – when a drawing has been given a new number. The state of the

previous number changes to Renumbered.

(h) Superseded – when new revisions of a drawing are released the state of the

previous revision changes to Superseded.

(i) Replaced – when a drawing is replaced with another drawing with a different

drawing number (i.e. not a new revision), the state of the previous drawing is

changed to Replaced.

22

As usual the distinction between a drawing and a document is not clearly stated here.

Documents include drawings and other 8½ by 11 sized documents. For the purposes of this

specification the words drawing and document are interchangeable, except where the difference

is important.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-36-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 49

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

stopping a process can be described by the state of the supporting documentation.

[31]

These

processes are the activities which are performed during the manufacturing of products or

maintenance of the manufacturing facilities. These processes make use of documents as their

fuel. Documents start a process, documents are referenced during the execution of a process

and documents are generated at the conclusion of the process.

It is desirable that all information pertaining to a given process be available to those who design,

construct, operate and maintain the process. This information may include: documents,

drawings, process specifications, measurement data, and process models. To ensure that

information can be shared within various applications it is necessary that these applications use

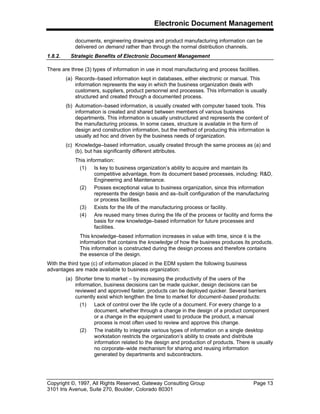

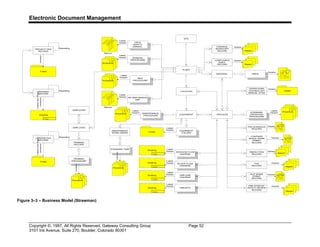

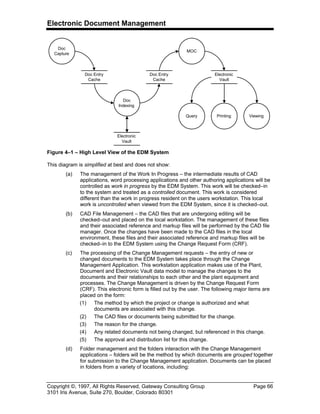

a common data model. Figure 3–2 describes how a common data model may be used by

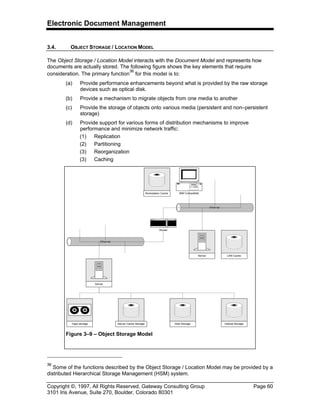

separate applications.

The notation used in this diagram is known as Gane & Sarson and has the following meanings:

EDMS

OSHA

Document

Control

P1

– describes a process, which contains a Process Number, a description of the

process, stated as an imperative sentence and the physical location where the process is

performed.

Project(s)

– describes a data set used by the process.

31

Reengineering the Corporation: A Manifesto for Business Revolution, H. Hammer and J.

Champy, Harper Business, 1993.

OSHA

Compliance Info

Process

Engineering &

Corporate

Procedures

Drawings

OSHA / ISO

Documents

Engineering &

Corporate

Specifications

New OSHA / ISO Documents

Maintenance

Documents

MarCam

Maintenance

Work Orders

P3

EDMS /

AutoManager

Drawing

Registry

P6

Equipment

EDMS

OSHA / ISO

Document

Control

P1

AutoCAD

CAD

Authoring

P7

Project

Management

Information

P2

Project(s)

Drawing

Creation

Project

Regulatory

Information

Engineering

MSDS

Maintenance

Training

Training Records

Health & Safety /

Environmental

QIS

Statistical

Process

Control

P5

FilesEmployee

Plant

Quality Information

System

QIS

Data Collection

P4

Parametric Data

Site](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-49-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 50

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

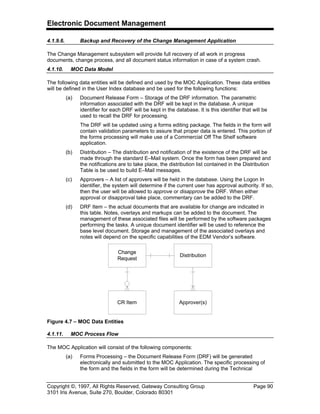

Figure 3–2 – Conceptual Framework for the EDM System.

Within the conceptual framework, there are seven (7) primary systems that are tied to processes

(Boldface systems denote suggested initial EDM applications):

(a) Project – this portion of the EDM System manages the creation and distribution of

project management documentation. This documentation will include project

specifications, manufacturing specifications, project information related to quality,

etc.

(b) Engineering this portion of the EDM System will manage drawings and related

technical documentation such as standard operation procedures, process

specifications, and PHA’s

(c) Regulatory Information this portion of the EDM System will serve as a

repository for regulatory information (ISO and OSHA) related to processes at a

facility.

(d) Training – this system will manage the training records associated with each

employee. This system will not be part of the EDM System but will interface with it

to gain access to training documentation and operating procedures.

(e) Maintenance – used to manage work orders associated with maintaining plant

equipment. The EDM System would provide the maintenance users with access to

drawings and related technical information.

(f) Health and Safety / Environmental – manages environmental and safety related

files.

(g) Quality Information System (Data Collection) – this system does not exist today.

Within the context of the Quality Information System, the EDM System could

control and manage: process specifications, standards, and other process

documentation.

3.1.1. Elements of the Conceptual Framework

The conceptual framework, shown in Figure 3–2, consists of Data Entities and Process Entities.

They are arranged using the Gane & Sarson

[32]

methodology, which constructs a logical model

of the system, containing both process and data elements.

3.1.1.1. Data Entities

The key data entities in the conceptual framework include:

(a) Site – this entity describes the various geographic locations that contain plants or

facilities.

(b) Process – this entity describes the various manufacturing processes.

(c) Equipment – this entity describes the equipment associated with a given process.

(d) OSHA/ISO Documents – this entity describes the various regulatory and quality

assurance documents.

(e) OSHA/ISO Compliance Information – this entity describes the various OSHA and

ISO documents that define the compliance activities.

32

Structured Systems Analysis: Tools and Techniques, C Gane and T. Sarson, Prentice–Hall,

1979](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-50-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 71

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

Provide

Document

Entry

Documents

Provide

Indexing and

Committal

Compresed

Images

RDBMS

EV

Cache

Storage

Optical

Disk

DBMS

Document

Class

Rules

Data

Model

Rules

Indexing

Commands

Provide

Document

Retreival

Indexing

Rules

Provide

Document

Printing

Provide

Document

Viewing

Compress

Image

Selected

Doc IDs

Print

Server

Viewing

Software

Provide

Document

Markup

Markup

Software

Overlays

Marked Up

Documents

Marked Up

Documents

Printed

Output

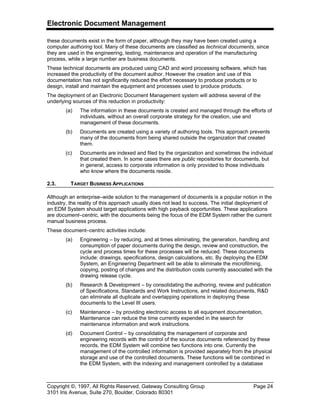

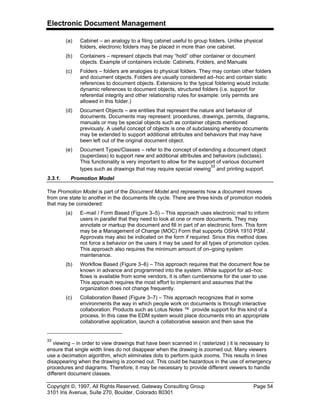

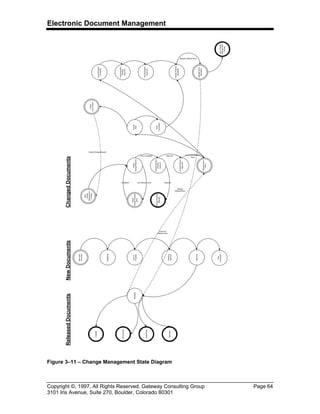

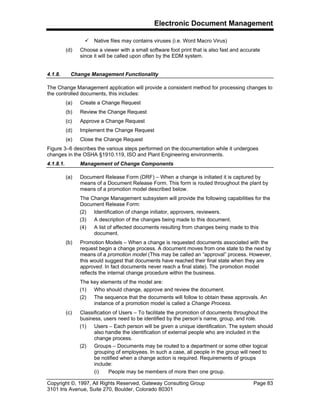

Figure 4–3 – Post Authoring Interactions of the EDM System.

[40]

The Document Management Application components that provide this post–authoring

functionality include:

(a) Provide Document Entry – which captures paper and electronic documents of all

sizes. Once entered, these documents will be placed in an indexing committal

queue for further indexing to the EDM System.

Documents stored in the EDM System may originate from several sources: CAD

drawings, word processor files and paper documents . All these documents are

captured through the Document Entry client application. This Document Entry

application provides a consistent point of entry for both electronic and paper

documents.

(1) Paper documents are scanned to an electronic image, which can be stored

and retrieved by the EDM System. Verification of the scanned image and its

40

The diagram show in Figure 4–3 uses the Structured Analysis Design Technique, described in

“Structured Analysis (SA): A Language for Communicating Ideas,” D. Ross, IEEE Transactions

on Software Engineering, Volume SE–3, Number 1, 1977. This methodology is used to show the

functions of the system, but not the order in which they are performed. It only shows that

information is passed between each of the required functions, the constraints placed on the

functions and the mechanisms use to provide the functions.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-71-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 72

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

preliminary indexing can be performed on a single workstation, under

programmatic control.

(2) Each page of the word processing file may be stored in one or more of three

(3) forms:

(i) A raster representation of the original word processing file,

(ii) The native word processing file.

(iii) Some form of rendered file format such as Adobe Acrobat or TIFF.

(3) CAD drawings are converted from their vector format to an industry standard

raster form with no loss of resolution or scale.

The Document Entry Application operates in conjunction with the Change

Management Application. These two applications share the following capabilities

as well as provide the following individual capabilities.

(4) Shared capabilities include:

(i) Capture and indexing of the documents.

(ii) Committal of documents to the Electronic Vault.

(5) Individual Capabilities:

(i) The Document Entry Application provides for management of the

scanning operations.

(ii) The Document Entry Application provides for the Back File

Conversion processing.

(iii) The Change Management Application provides for the logical indexing

and committal of all documents.

There are several activities, which will not be addressed by the Document Entry

application:

(6) The application of the Professional Engineers Stamp or physical signatures

applied electronically to the documents will not be handled by the

application. All official stamps and signatures must be applied prior to the

scanning and committal of documents.

(7) The capture of electronic documents will only support the conversion of CAD

drawing generated from AutoCAD .DWG files. The supplier of these files

must provide the indexing information in a hardcopy format, since the EDM

System will not provide the extraction of the title block information.

(b) Provide Indexing and Committal – using the documents placed in the committal

queue, the EDM System Document Entry operator will keyboard the detailed

indexing information for each document. Multiple–page documents will be indexed

as a complete document, with the individual pages addressable once the

document has been retrieved from the EDM System.

[41]

Individual page

documents or drawings will be indexed without page numbers. In all cases the

minimum information to be captured will be the drawing number, sheet number

and revision number.

41

The current system design assumes a sheet based document storage system. An alternative

to the sheet based system is a document based system. In the sheet based system, each sheet

or page of a document can be addressed individually. In the document based system, only the

document in its entirety can be addressed. For engineering drawings, individual sheets have

revision and version numbers assigned, thus requiring a sheet based system.

In a sheet based system, the replacement of a single page of a document or a single sheet of a

drawing can be made, without re–committing the entire document.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-72-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 73

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

The indexing fields will be derived from the Document Class information

maintained in the EDM System Data Model. This information will be used to define

the fields on the indexing form, as well as provide attribute validation for these

fields.

Entry of new documents, which replace existing documents, will be recorded as

revisions. The indexing information for the existing database entry will be

maintained, with the revision number increased to reflect the new version.

(c) Provide Document Retrieval – provides the primary document access method for

the EDM System. The user enters a query using a graphical or forms based entry

screen. The EDM System returns a list of documents that match the query. This

list can then be used to:

(1) Print the document(s) using the EDM System Print Services facilities. This

function will be accessed using the appropriate development tools

recommended by the EDM System Vendor.

(2) View the document(s) using client viewing application. The workstations of

the EDM System will be equipped with a RedLine / Markup package. The

underlying document format will be shared between the RedLine / Markup

and Viewing applications.

(3) The EDM System database will provide an indication that Markups have

been applied to a document.

(d) Provide Document Markup – using a markup and redline application, existing

raster images can be marked up or annotated to indicate changes or suggestions.

The EDM System Vendor in the form of a native or third party product will provide

the markup software. The EDM System will perform the management of these

markups. In the current implementation, the markups will be kept in a private

folder assigned to the user. This folder will be created when the user indicates that

markups will be applied to the raster image. If the user wants to place the markups

(and the associated raster image) in another folder, then the system will allow the

selection of another folder, but the connections to the raster image will need to be

addressed, depending on the limitations of the EDM System Vendor’s software.

The management of the markups and annotations will depend on the specific

functionality of the application software. There are two (2) general methods for

managing these markups:

(1) The markup application places the markups inside the file of the document

that is being edited. The markups and annotations then become an integral

part of the document, making it a new document in the sense of change

control. The viewing of the markups is available to users running the markup

application, since the markups are physically attached to the checked–in

document. No external management of the markups are required by the

EDM System.

Although this approach is simple and very useful, the primary problem is that

multiple users cannot apply markups at the same time. In the current

business environment this may be a serious limitation.

[42]

42

It should be noted that this limitation might be artificial in many applications. In the OSHA

§1910.119 environment the number of times concurrent markups are being applied is limited. In

a concurrent engineering environment, where changes are constantly being made to drawings

and document, multiple accesses to the same base document may be required. This internal

storage method eliminated the need to manage markups externally, and eliminates much of the

complexity of the Change Management application and the storage issues described in §4.6](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-73-320.jpg)

![Electronic Document Management

Copyright ©, 1997, All Rights Reserved, Gateway Consulting Group Page 95

3101 Iris Avenue, Suite 270, Boulder, Colorado 80301

(c) Markup

(d) E–Mail

(e) Printing

(f) Document Check–In and Check–Out

(g) System Administration

4.1.14.4. Database Attributes

The EDM System integrity will be based on a data model. The details of this data model will be

developed in the Technical System Design (TSD).

[44]

The database engine used to support this

data model will be capable of the following:

(a) SQL*Net attachment from the workstation.

(b) Support for triggers used during the table update process.

(c) Support for stored procedures.

4.1.14.5. Client/Server Attributes

The term client / server can be used to describe a variety of hardware and software

configurations.

[45]

The EDM System will make use of several application servers. Each server

will perform a specific function in the system, usually requiring dedicated computing resources in

order to maintain performance or reliability requirements.

These servers include:

(a) Shared File or Cache Servers – in which one or more computers with large disk

capacities are shared among a group of workstations using some form of file

mapping software. These servers will be used to store work in progress and

documents that are accessed temporarily by a user. Documents will be cached in

these servers for rapid retrieval to the user’s workstation. The placement of

documents in the cache will be determined by their usage, importance and

performance requirements.

(b) Database Servers – use a data request architecture, which provides clients with

requested information contained in the database. Stored procedures can be used

to improve the performance and extend the capabilities of the database server.

The indexing information contained in the database server will be used to locate

documents, define the business rules for managing the documents and managing

the physical and logical organization of the Electronic Vault.

(c) Cooperating Servers – in a typical EDM System architecture these services are

accessed by name. When the service has completed the requested work, the

information will be returned to the client. Neither the client nor the server requires

any addressing information about each other. The server application programs

may reside on any platform in the system and may be moved administratively for

improved performance.

44

These documents will follow the SRA. The Functional Specifications Document defines the

detailed behavior of the user interface and various software and hardware components if a

Systems Integrator is required. The Technical System Design will define the details of the

system implementation and deployment.

45

Since the current computing environment is centered on a mainframe and a set of terminals,

some background in the client / server architecture seems appropriate.](https://image.slidesharecdn.com/electronicdocumentmanagementtutorial-190317184835/85/Electronic-document-management-tutorial-95-320.jpg)