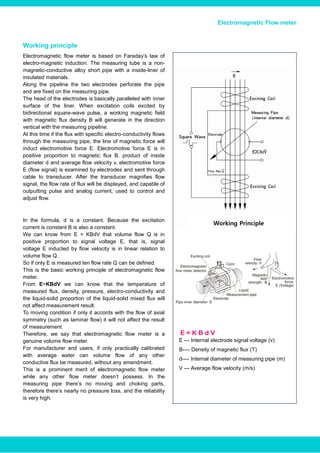

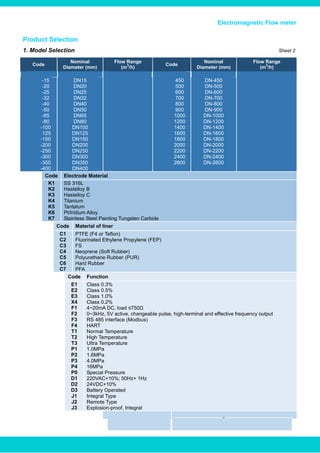

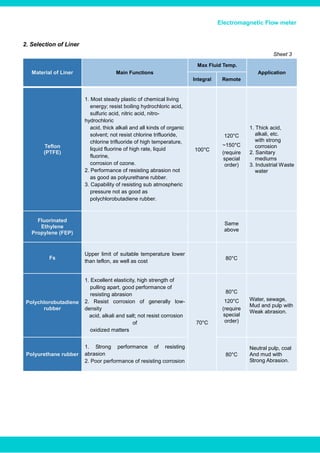

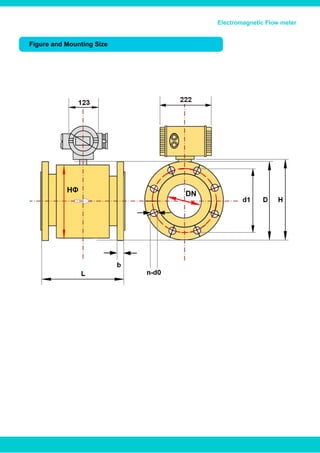

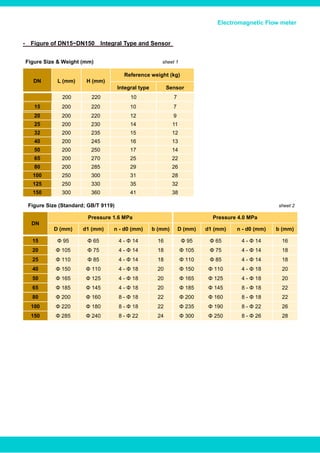

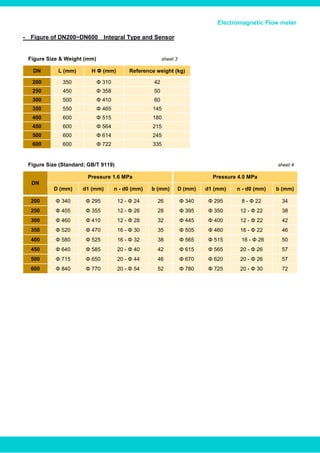

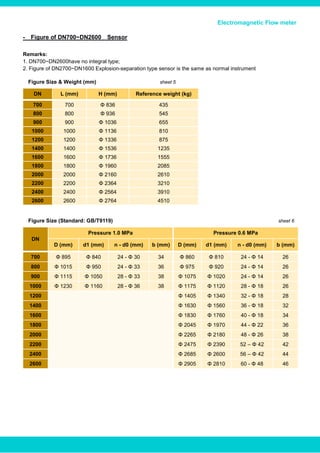

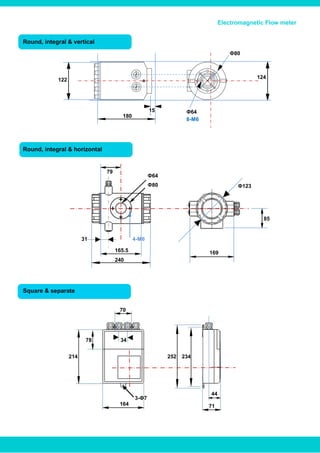

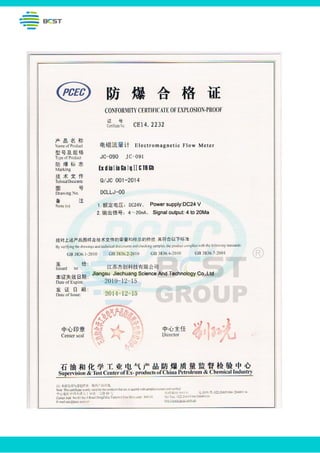

The document provides detailed specifications and features of an electromagnetic flow meter designed for measuring the flow of conductive fluids across various industries. Key features include high accuracy, quick response, and versatility for different mediums, with options for integral or remote installation. It also includes technical data, materials used, and operational conditions for effective measurement and user calibration.