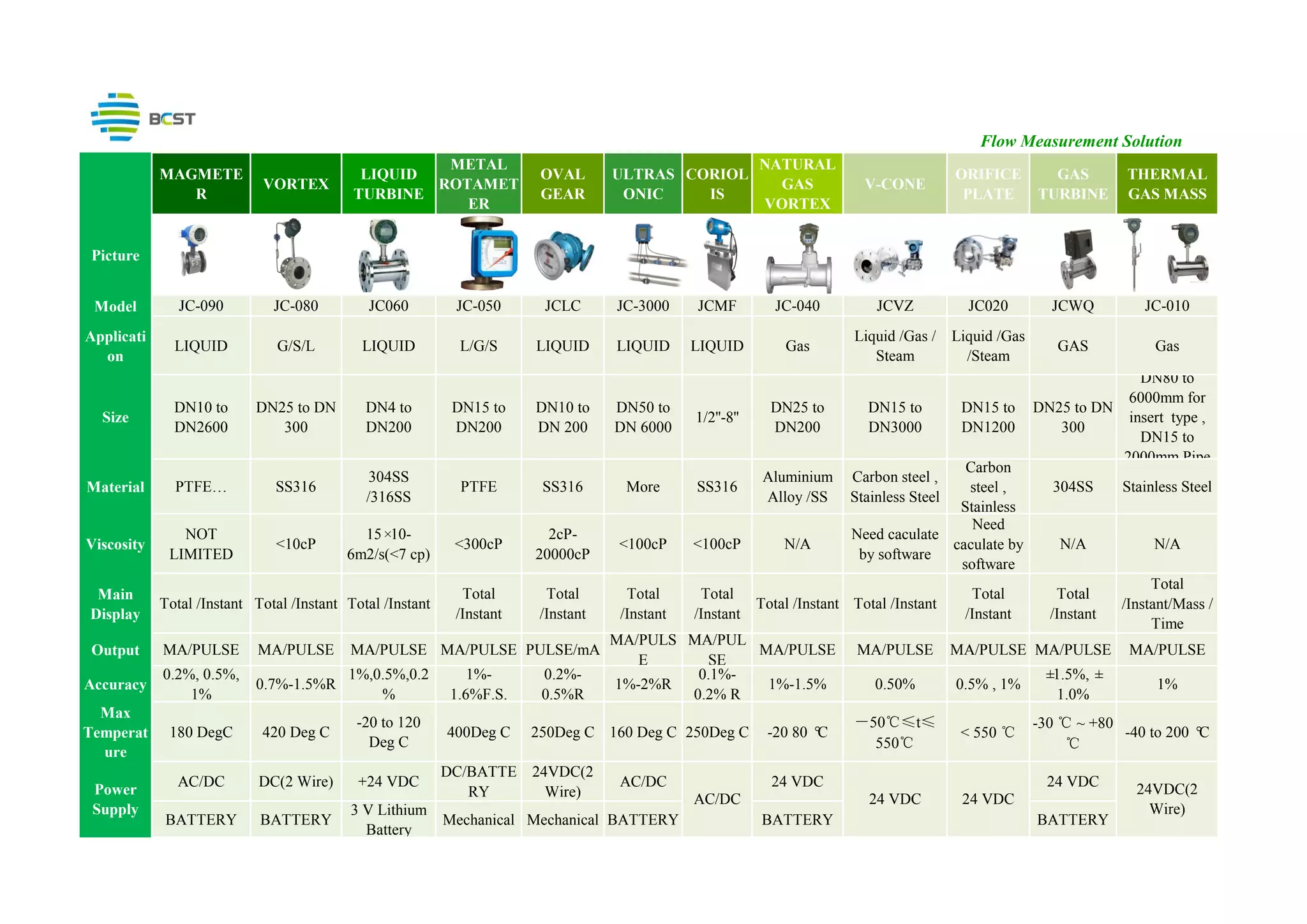

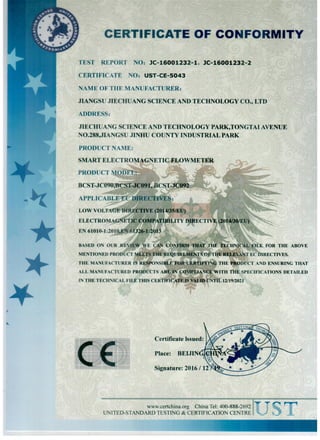

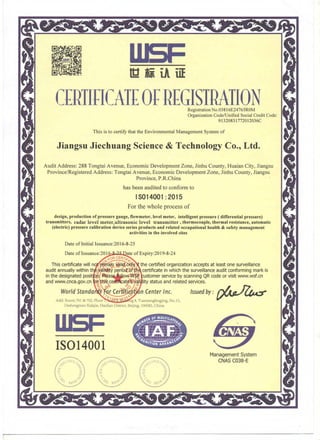

This document provides information on various flowmeter models from Jiangsu Jiechuang Science and Technology Co., Ltd. It lists 12 models of flowmeters from JC-090 to JC-010 that can measure liquids, gases, and steam with pipe sizes ranging from DN10 to DN6000. Key specifications listed include material, viscosity range, accuracy, temperature range, power supply, and more. It also provides a functional safety verification certificate from Ente Certificazione Macchine, verifying that several of the listed models are capable of safety instrumented function (SIF) applications up to SIL 2 level when properly designed into the safety system.