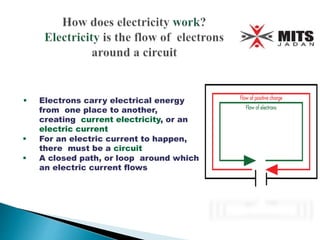

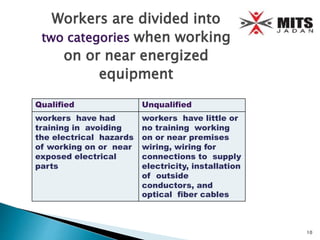

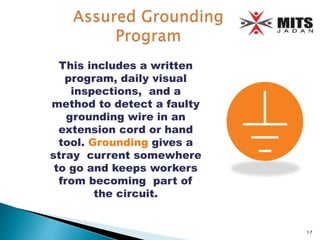

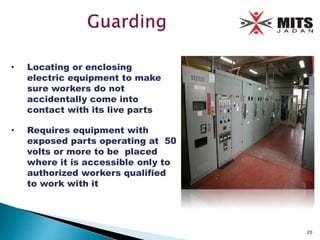

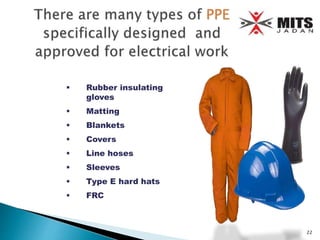

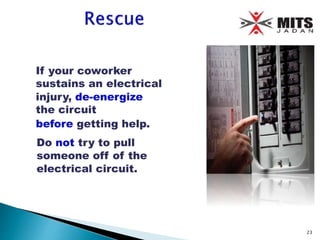

This document summarizes electrical safety procedures for workers. It discusses the basics of electricity, including voltage, current, and power. It then outlines various electrical hazards like shock, arcs, and faulty equipment. The document details safety requirements for qualified and unqualified workers, including following lockout/tagout procedures, grounding programs, and using GFCIs and insulating equipment. It emphasizes that if a coworker sustains an electrical injury, the circuit should be de-energized before providing help.