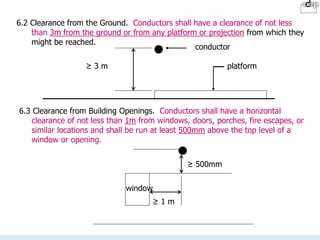

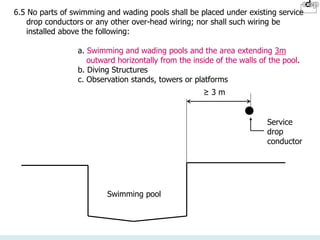

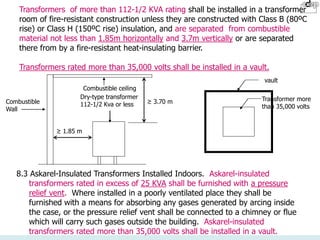

The document outlines electrical regulations regarding the installation and maintenance of overhead transmission and distribution lines, emphasizing safety, aesthetic considerations, and public convenience. It specifies locational requirements for poles and power lines, including minimum clearance distances from roads and buildings, and provides guidelines for how electrical equipment should be installed in various environments to prevent hazards. Key topics include clearances for power lines, attachments on buildings, requirements for transformers, and construction standards for transformer vaults.