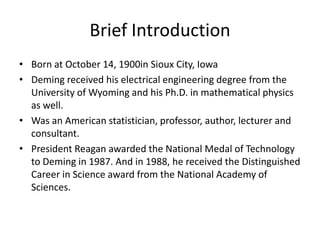

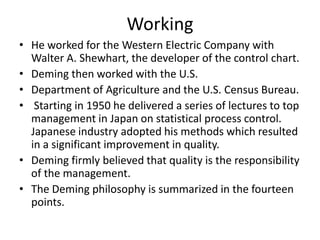

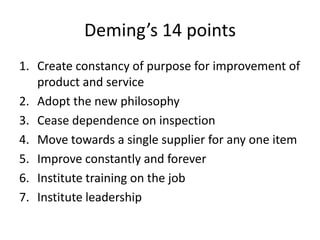

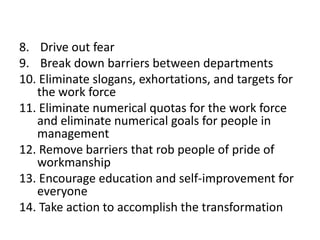

Dr. W. Edwards Deming was an American statistician and consultant who developed theories of quality management that came to be known as Total Quality Management (TQM). He taught Japanese businesses about statistical process control after WWII, helping them achieve major quality improvements. Deming's 14 Points outline his philosophy that quality should be the responsibility of management and continuous improvement is needed. His emphasis on customer focus, defect prevention, and teamwork revolutionized business practices and had a major impact on industries worldwide.