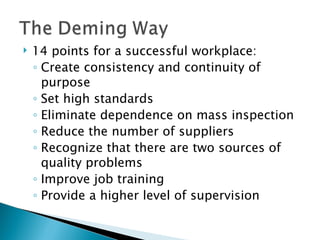

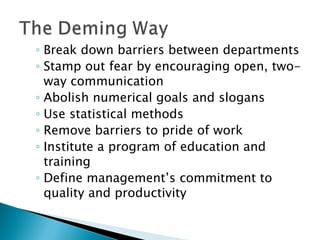

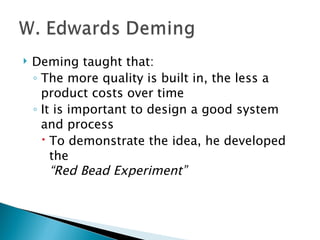

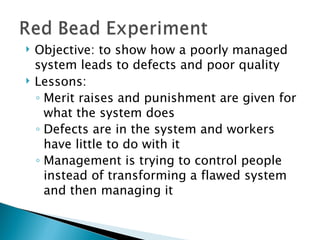

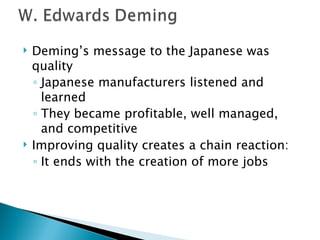

The document discusses the history and philosophy of the quality movement. It explains that the quality movement aims to empower workers by recognizing that those closest to the work have the best understanding of how to improve quality. A key figure was Dr. W. Edwards Deming, who influenced Japanese companies and their emphasis on continuous quality improvement through statistical process control and employee participation. Deming taught management to focus on designing quality into processes rather than inspecting for defects.