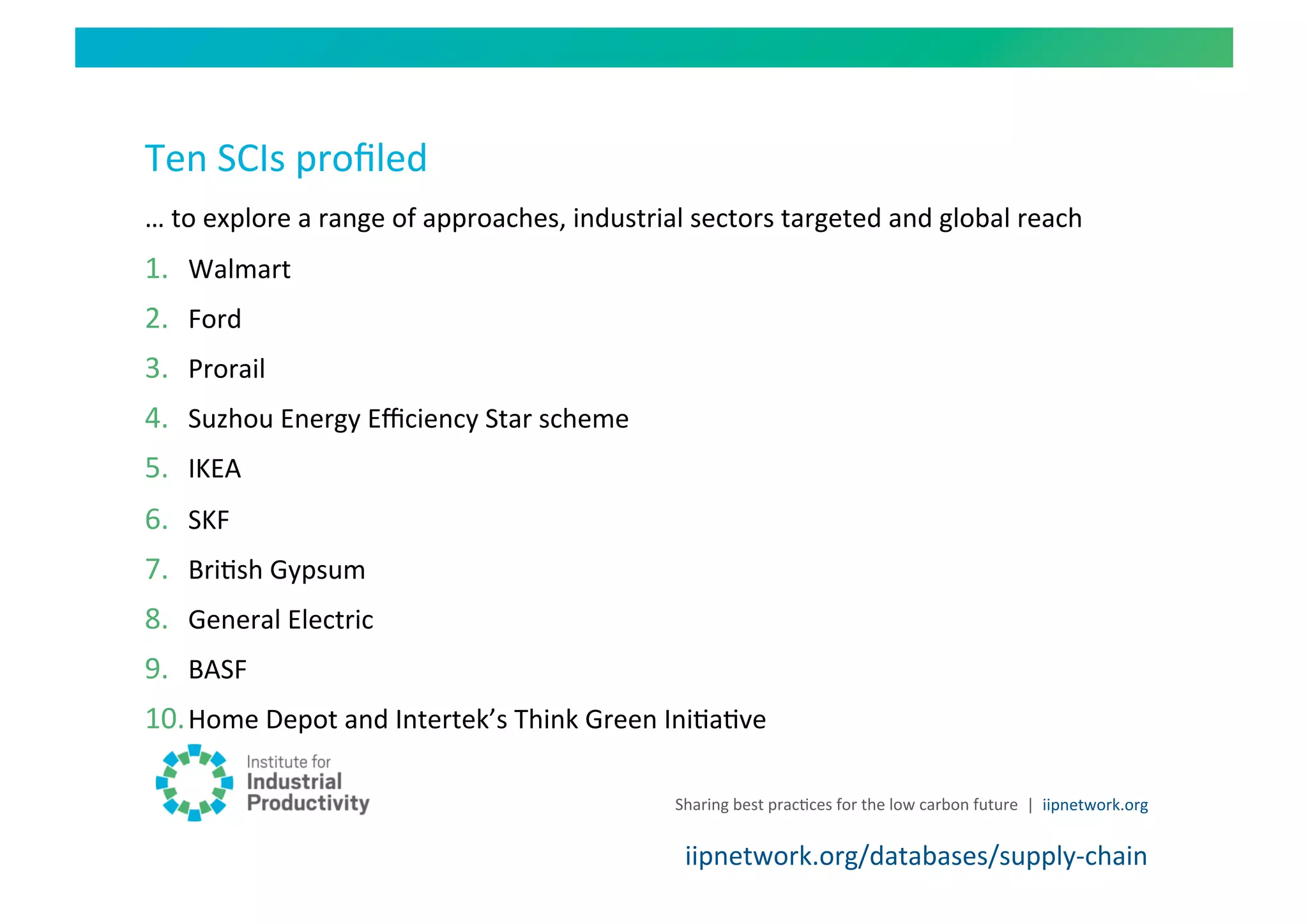

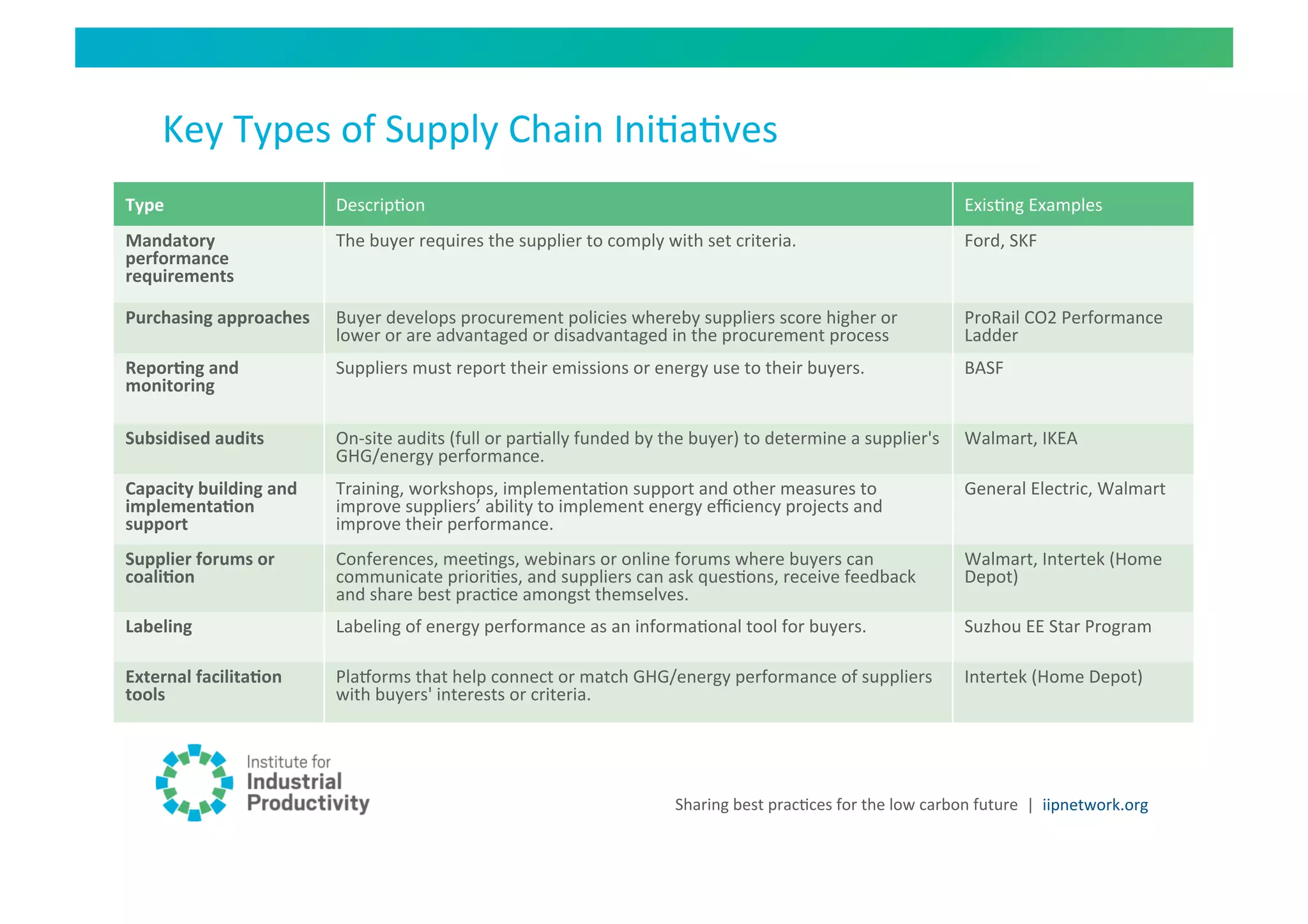

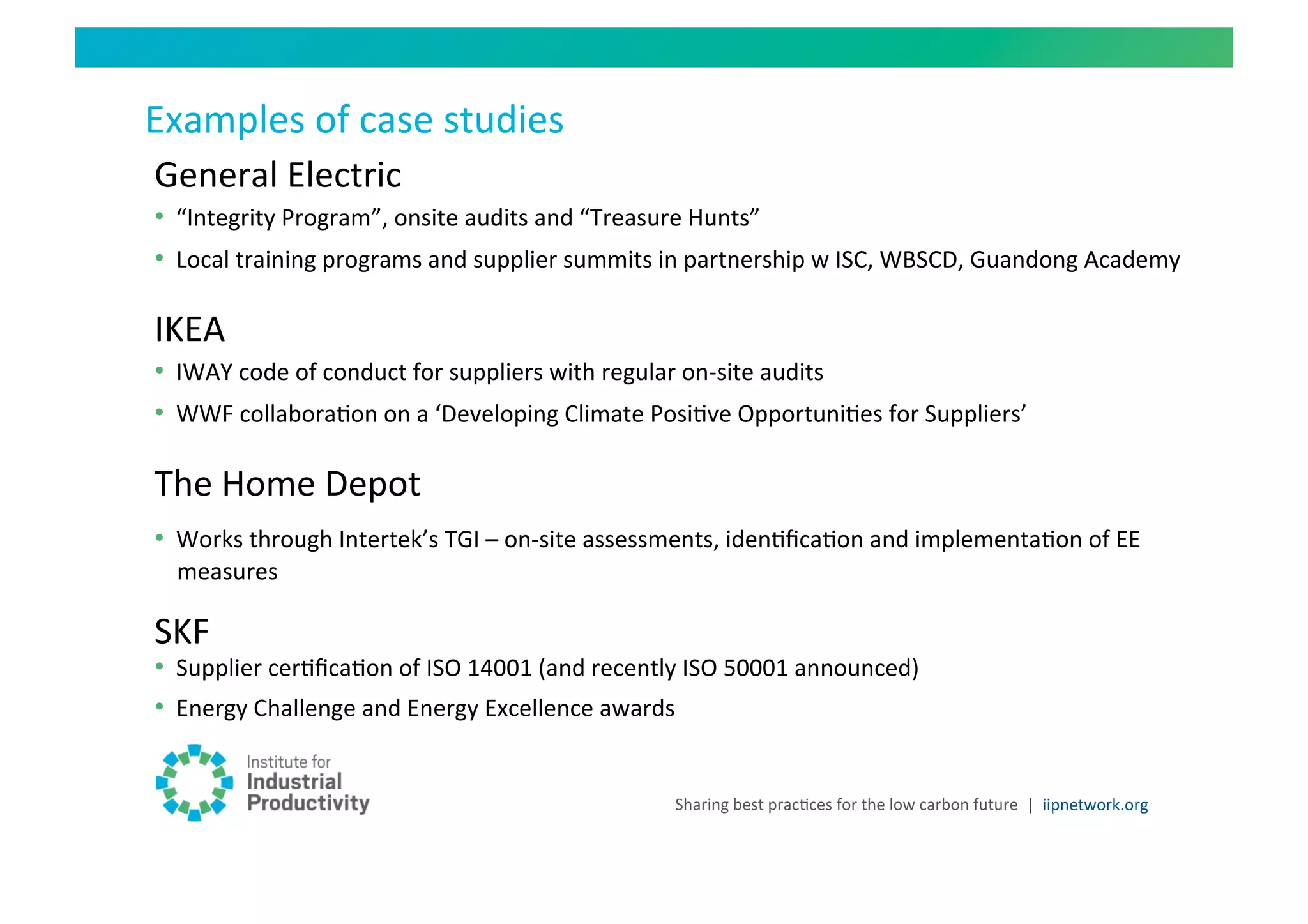

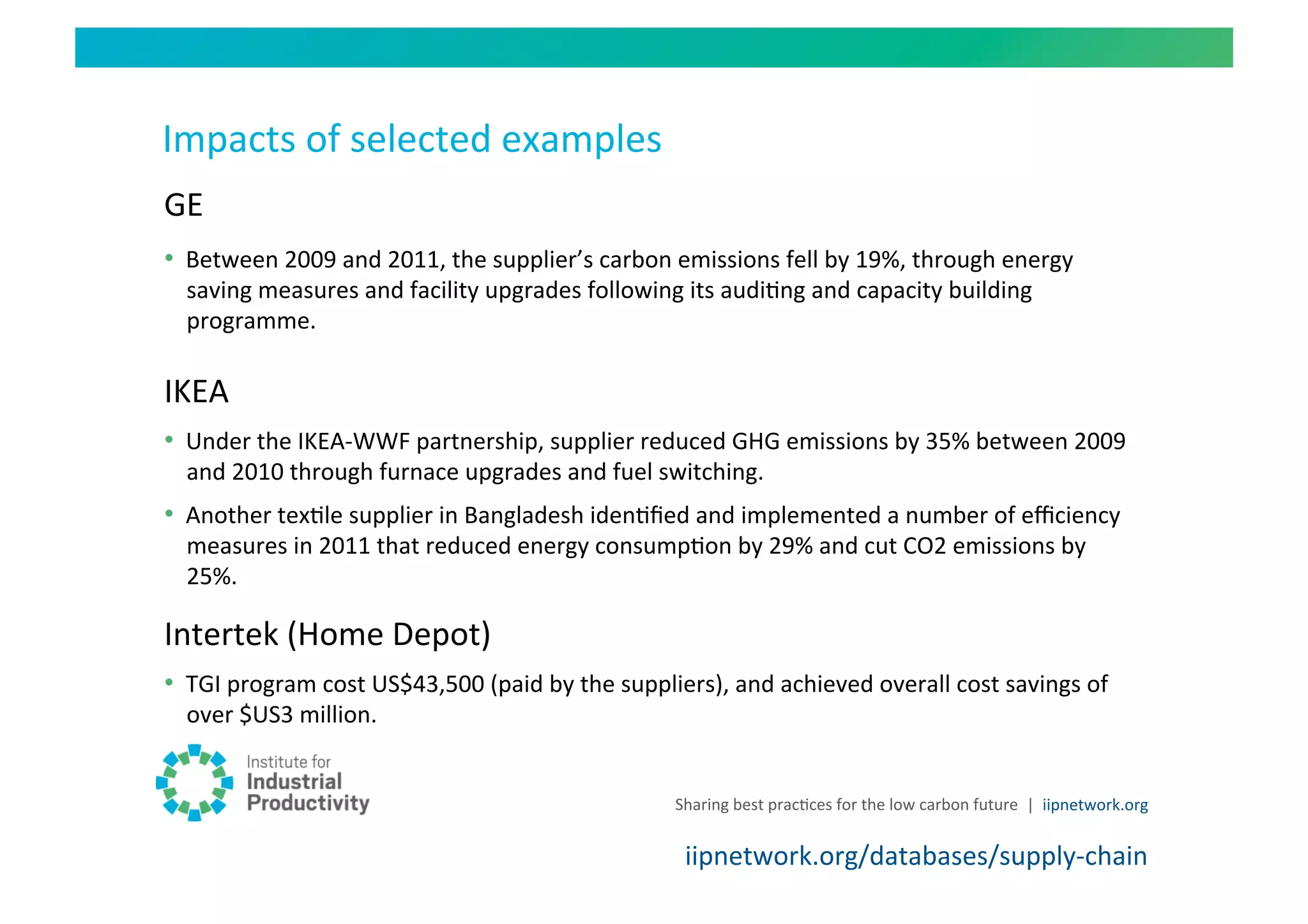

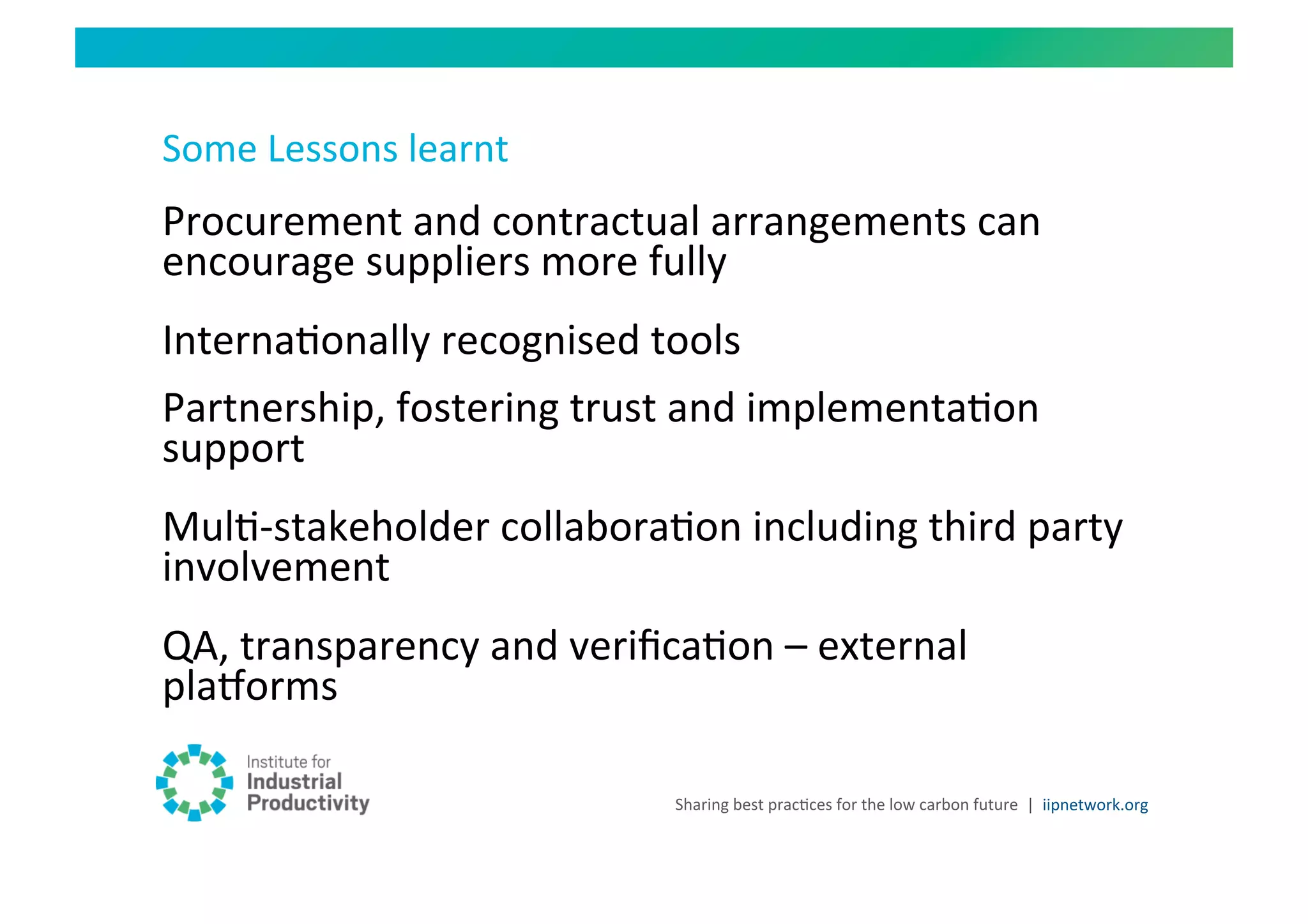

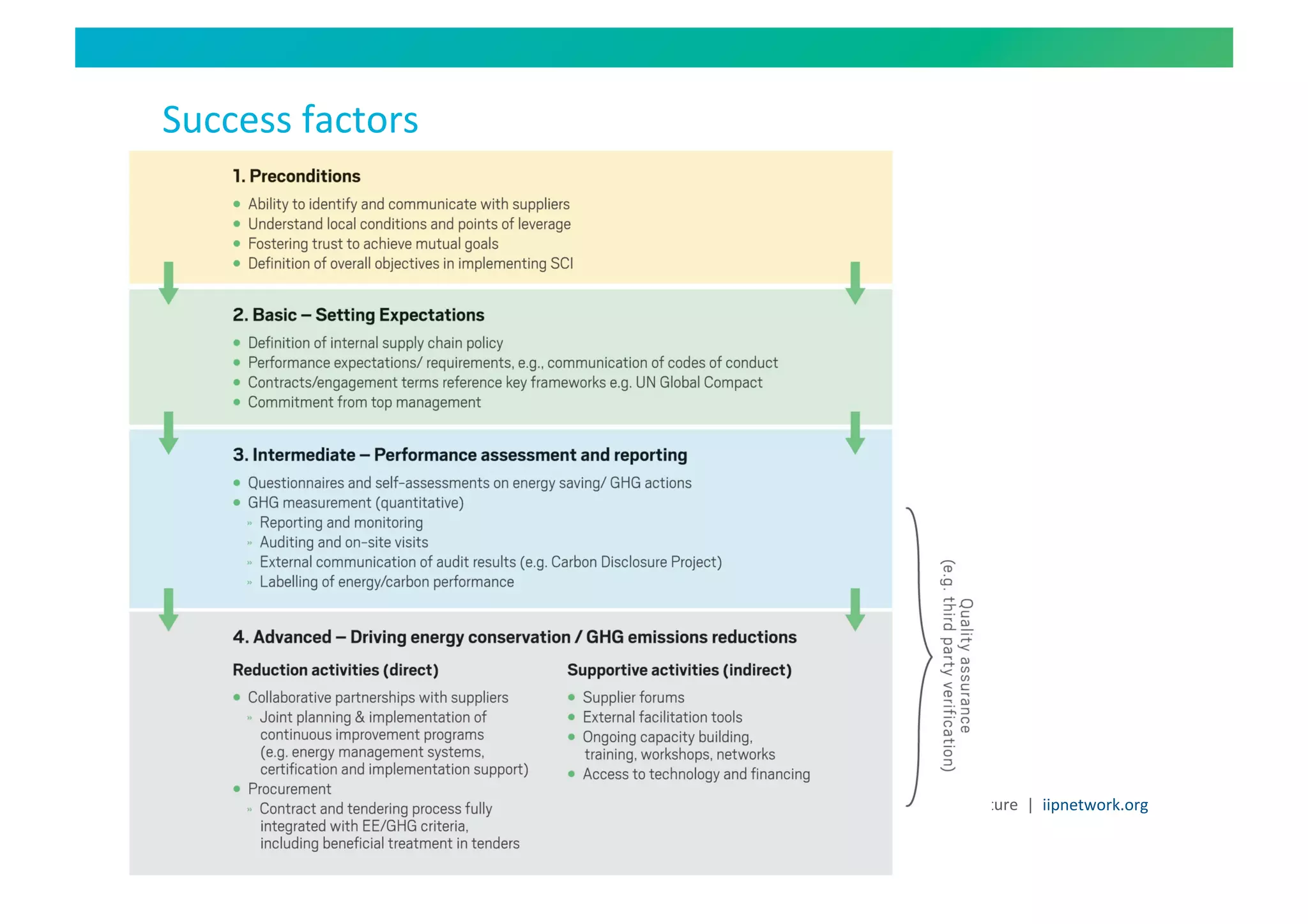

This document profiles ten supply chain initiatives that aim to promote energy savings and greenhouse gas mitigation. It finds that such initiatives show promise in achieving environmental goals across international borders and among disparate businesses. Key approaches include mandatory performance requirements, procurement policies, reporting/monitoring, audits, capacity building, and forums. Case studies on GE, IKEA and Home Depot yield examples of energy and emissions reductions from 19% to 35%. Lessons include using procurement to encourage suppliers, internationally recognized tools, partnership/trust, and third-party involvement.