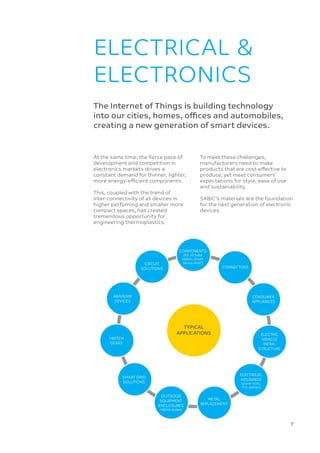

SABIC provides thermoplastic resin solutions for various electrical and electronic applications. They offer a range of materials including polycarbonate (PC), polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS), and acrylonitrile-styrene-acrylate (ASA) resins that provide benefits such as flame retardancy, high heat resistance, impact strength, and design flexibility. These materials are used in applications including housings, connectors, switches, and other components for electronic devices, infrastructure, and lighting. SABIC has expertise in material development, processing, and application support to help customers drive innovation.