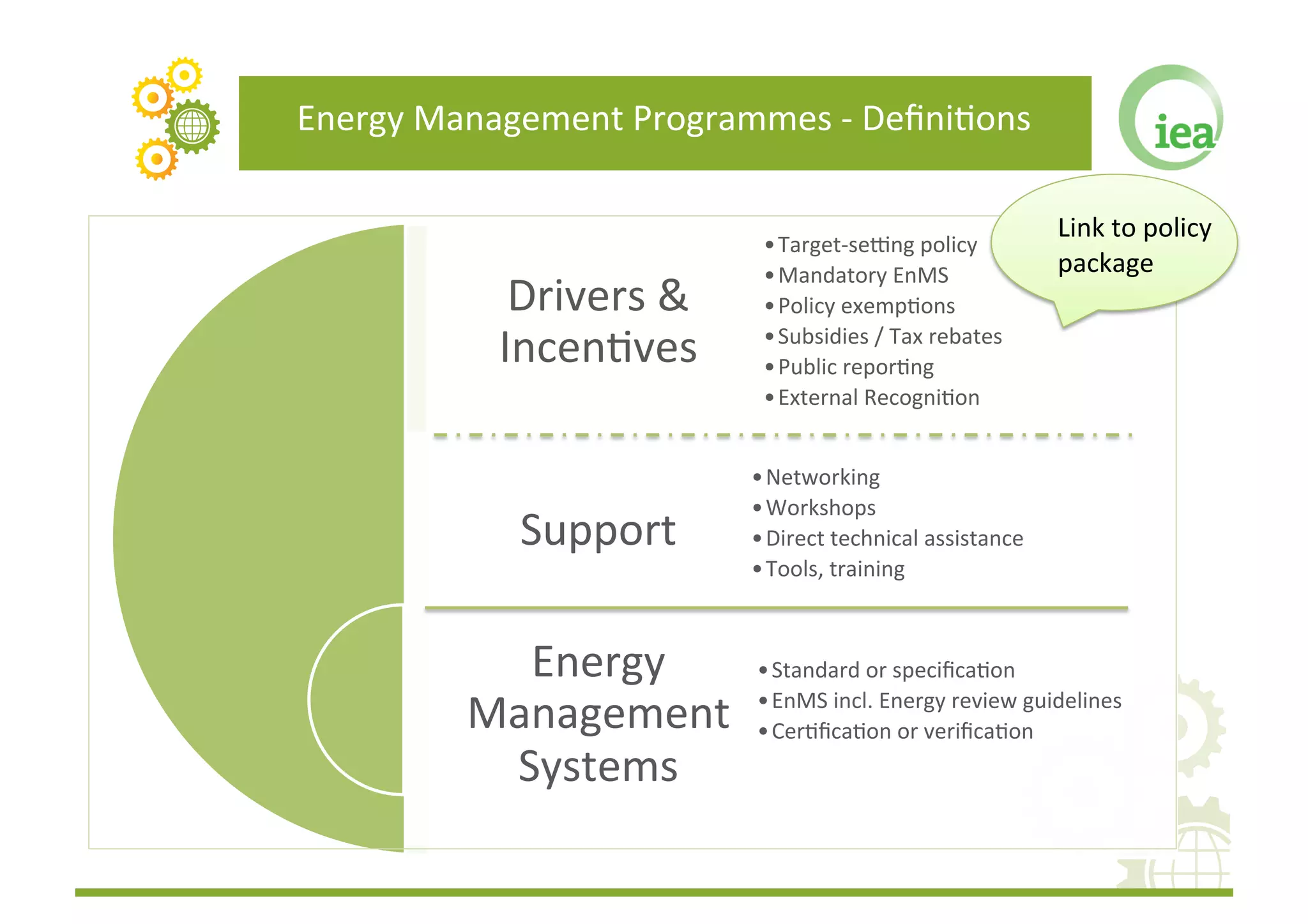

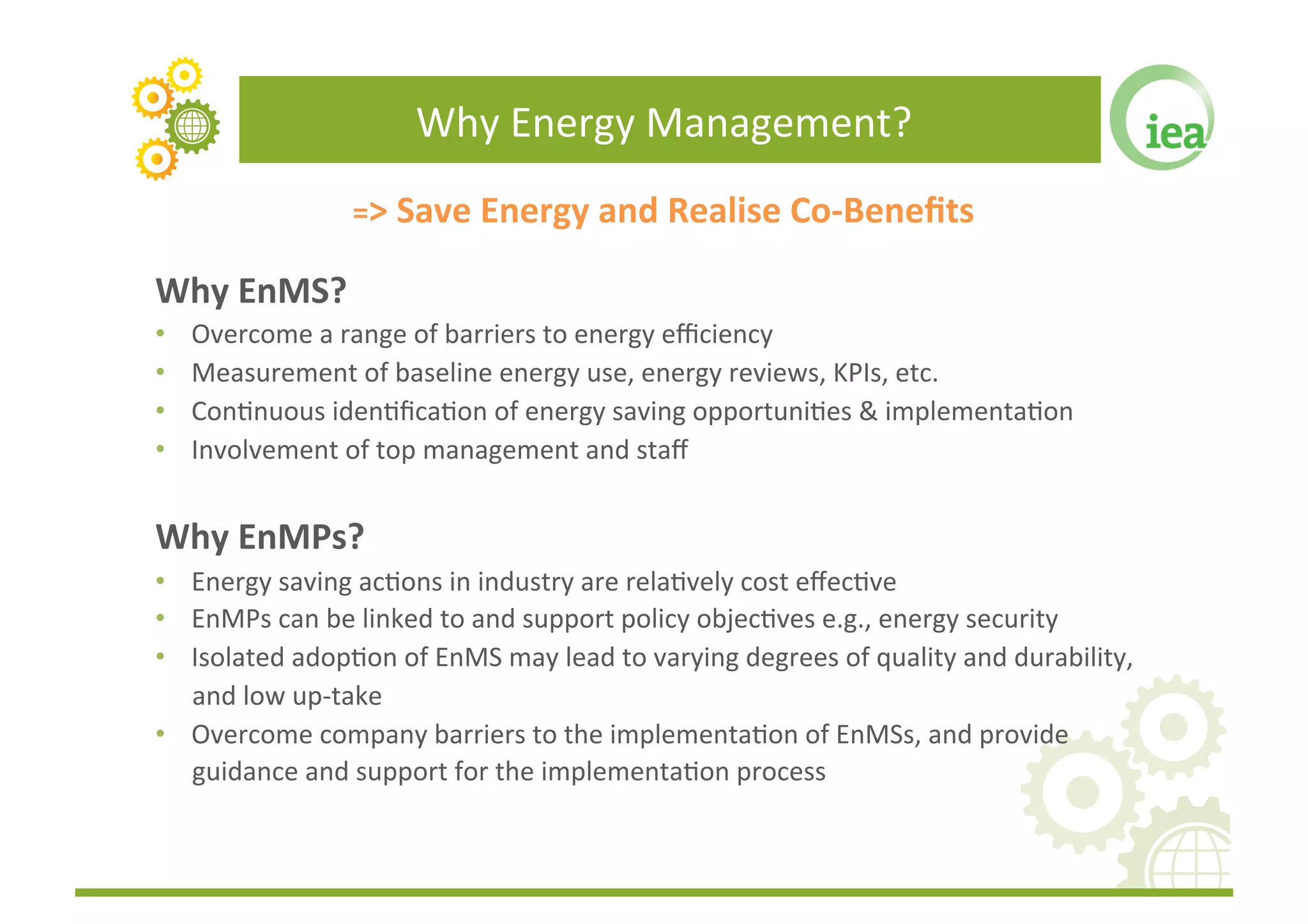

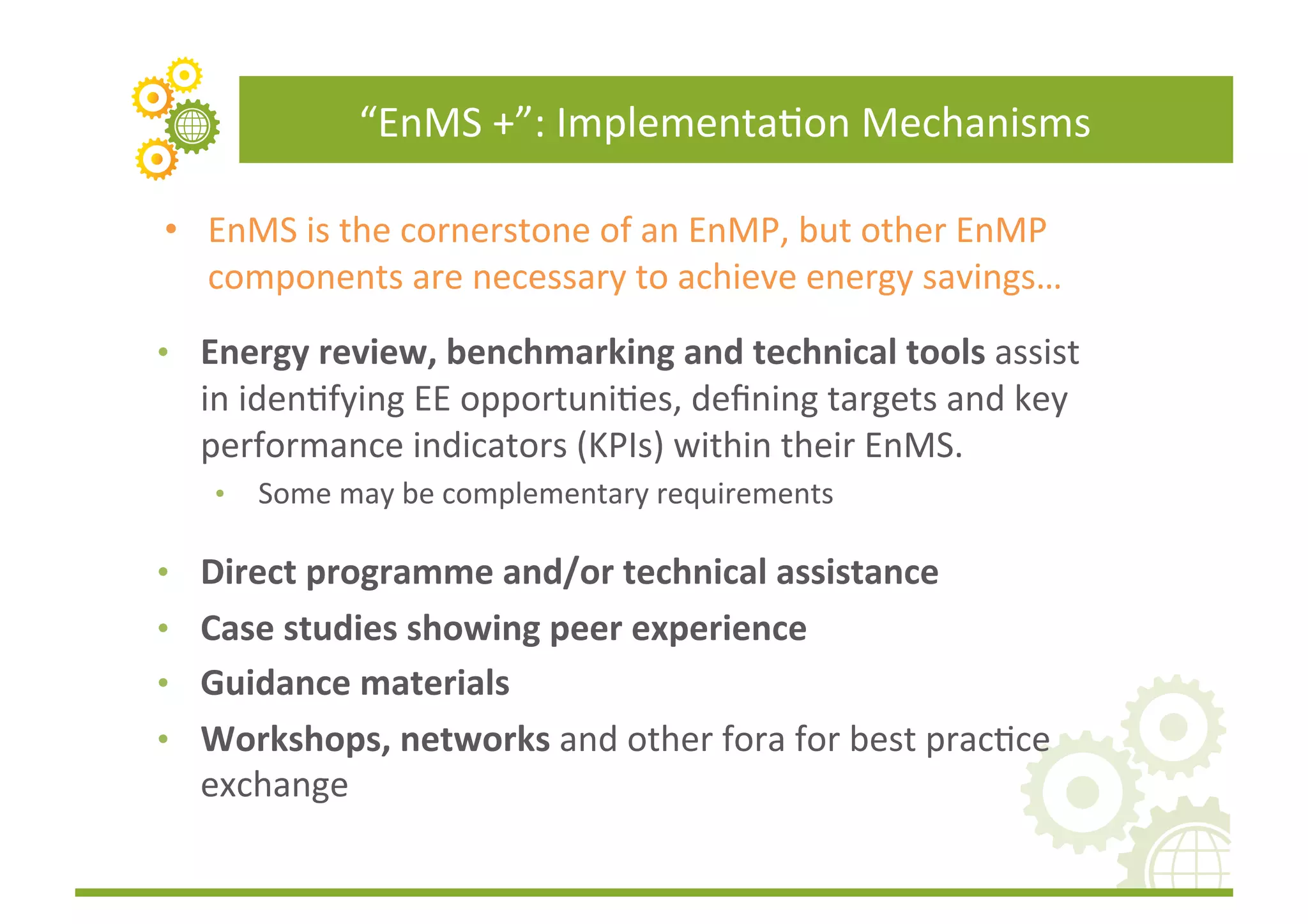

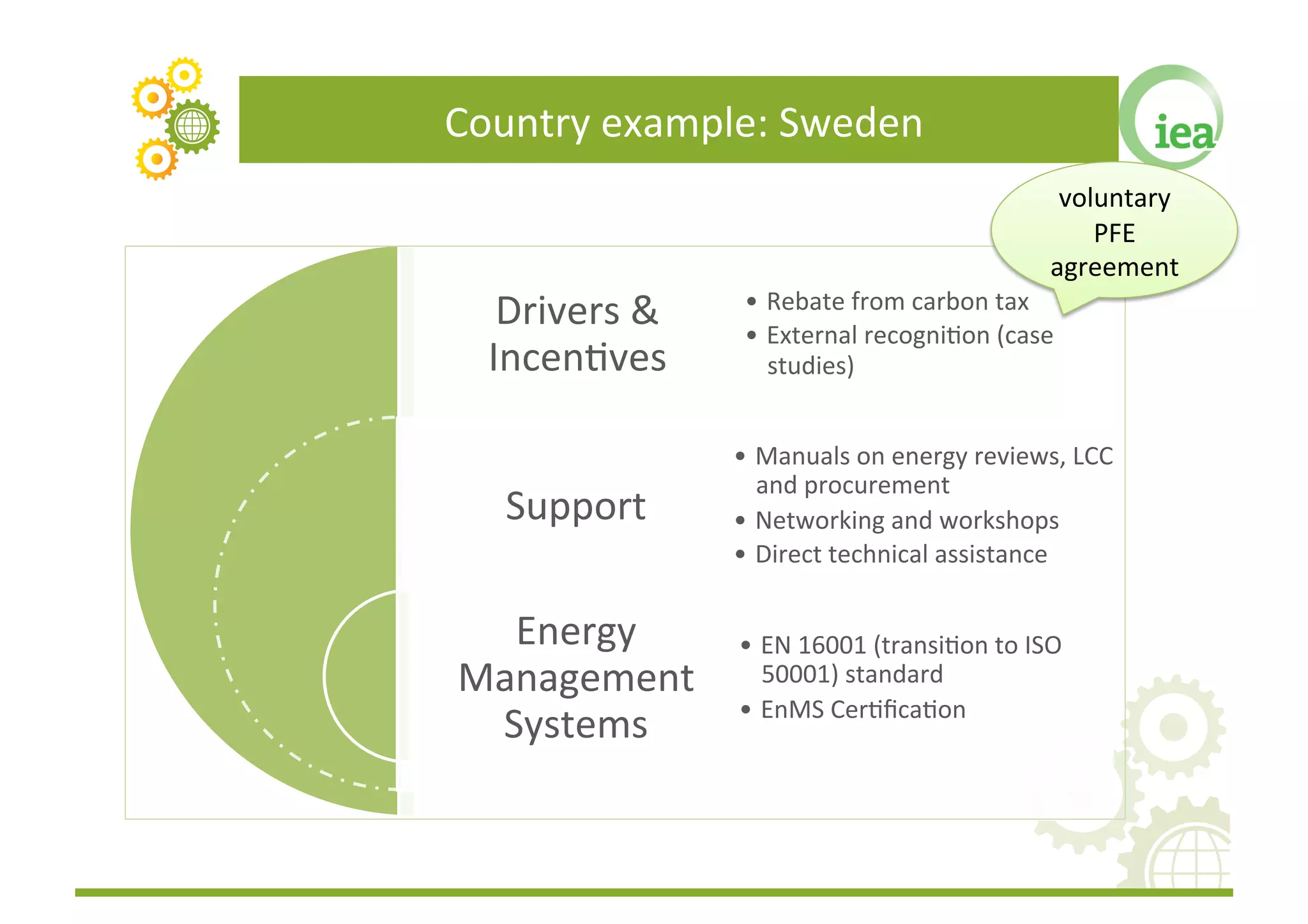

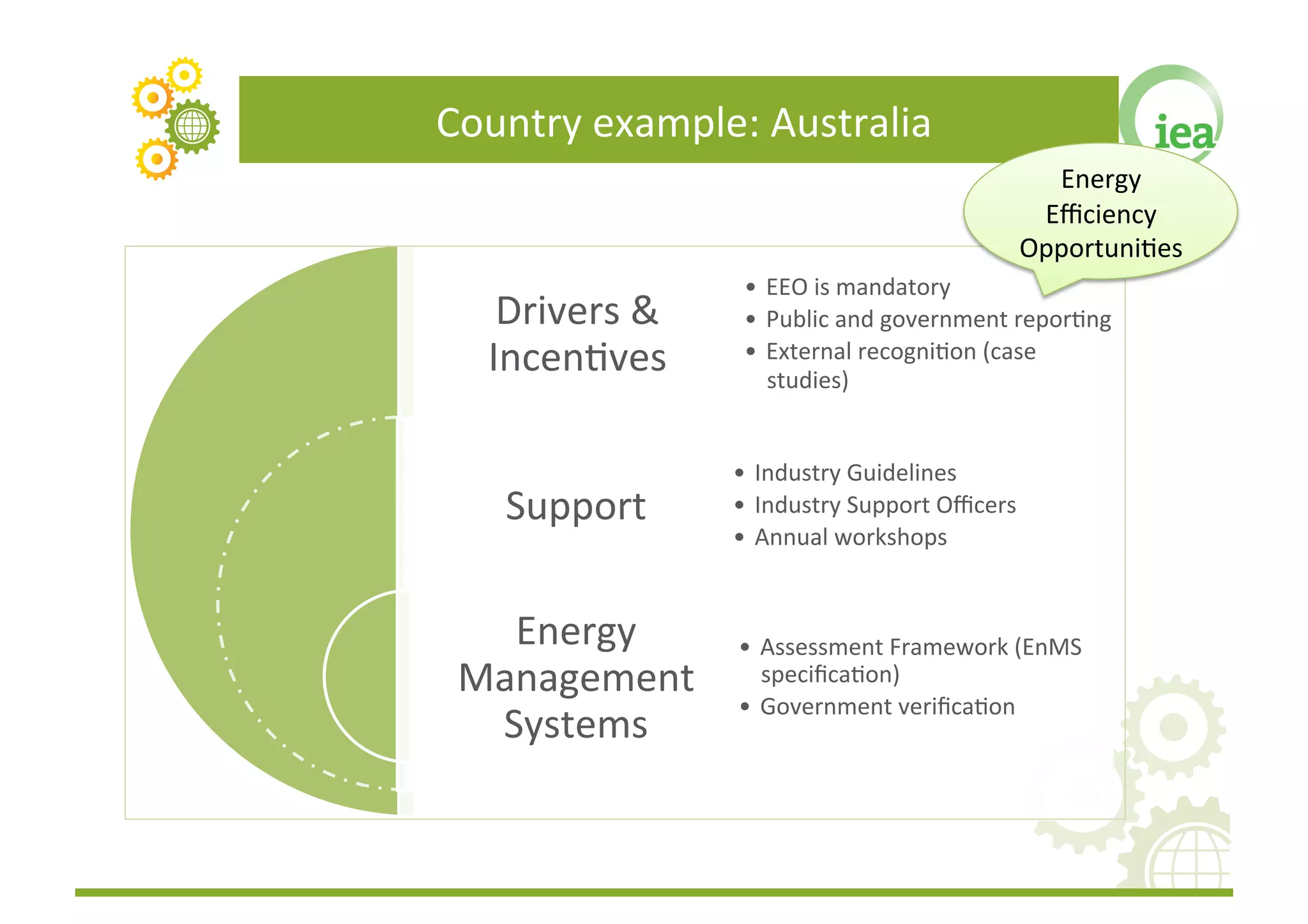

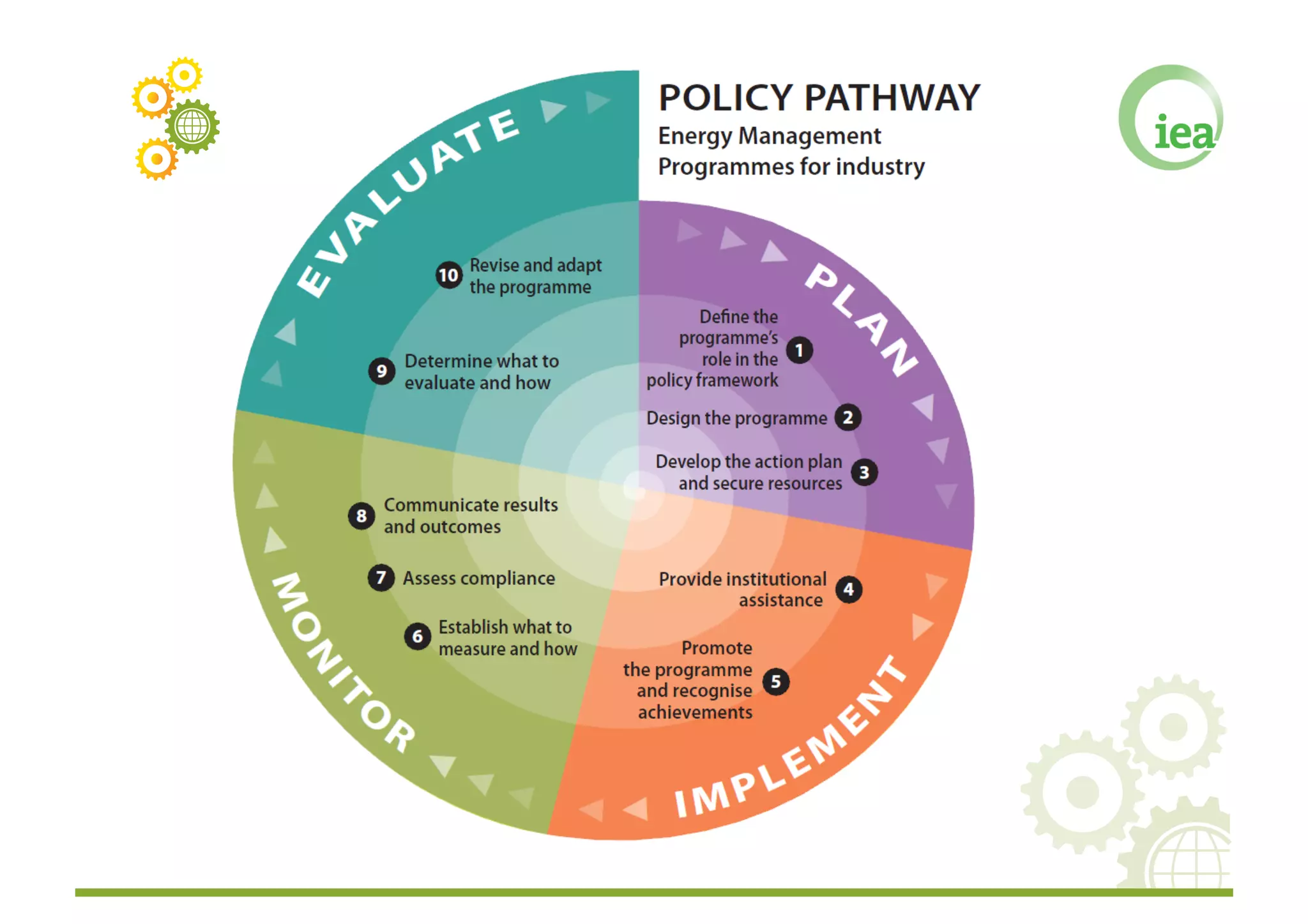

The document discusses energy management programs (EnMPs) and their importance for reducing energy use and costs in industry. It provides an overview of the Institute for Industrial Productivity's relevant research on EnMPs, including case studies of programs in various countries and guidelines for designing and implementing effective EnMPs. The key components of successful EnMPs are establishing energy management systems, while also providing drivers, incentives, and implementation support for companies.

![Decision-‐makers

Ma]er!

Need

to

make

a

compelling

business

case

to

the

board

Produc(vity

gains

“sell”

Chief Technology Officer

“Do we know what energy efficiency

practices and technologies are

available?” Financial Director

Driver: knowledge Do we have the money to invest

and are we willing to spend it on

EE?

Driver: Financials

CEO

Are we committed to prioritize EE

above other investments?

Driver: Commitment

Source:

Ecofys

in

Reinaud

and

Goldberg,

2011

Marketing Director

Do the public and market demand

us taking EE measures?

Driver: Public and market Regulatory Affairs Officer

demand Does this government policy

require us to take EE measures?

Driver: Policy obligation](https://image.slidesharecdn.com/eeglobalmar2012pres-120426082602-phpapp02/75/Pathways-to-Energy-Management-Programmes-Gaining-through-Saving-Amelie-Goldberg-5-2048.jpg)

![EnMS

in

the

Supply

Chain

What

is

the

role

of

EnMS

in

supply

chain

ini(a(ves?

• Successful

examples

of

large

buyers/retailers

engaging

their

manufacturing

base

in

energy

or

GHG

saving

acFviFes,

e.g.:

• Ikea

audits

and

capacity

building

with

its

manufacturing

suppliers

(partnership

with

WWF

Climate

PosiFve

OpportuniFes

for

Suppliers)

• Ford

and

SKF

require

suppliers

to

be

ISO

14001

cerFfied

• IIP

Database

on

Supply

Chain

IniFaFves

for

Industry

(April)

• ISO

50001

–

an

internaFonally

recognised

a

framework

for

organisaFons

to

encourage

suppliers

to

be]er

manage

energy](https://image.slidesharecdn.com/eeglobalmar2012pres-120426082602-phpapp02/75/Pathways-to-Energy-Management-Programmes-Gaining-through-Saving-Amelie-Goldberg-14-2048.jpg)