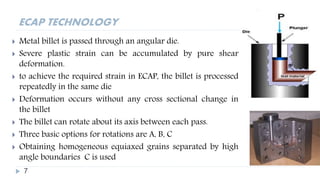

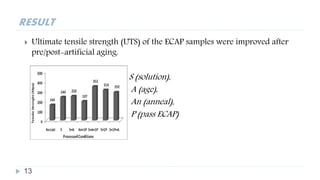

The document discusses improving the mechanical properties of an aluminum alloy (A356) using equal channel angular pressing (ECAP) and heat treatments. ECAP is used to refine grains and increase strength according to the Hall-Petch relationship. The aluminum alloy was subjected to ECAP along with various heat treatments including annealing, solutionizing, and aging. Testing showed the best properties were achieved with solutionizing followed by ECAP and aging, increasing tensile strength from 160 MPa to 352 MPa while also improving ductility. Thus, suitable heat treatments combined with ECAP can significantly enhance the mechanical properties of aluminum alloys.