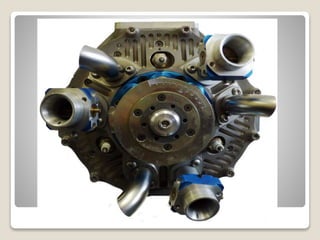

The Duke engine is a four-stroke axial reciprocating engine where the cylinders are aligned with the central crankshaft. It is lightweight, compact, valveless, and vibration-free with high power density. The Duke engine can run on various fuels including gasoline, ethanol, diesel, and kerosene. It is well-suited for aerospace, marine, and light aircraft applications due to its small size, low weight and vibration, and ability to run on multiple fuels.