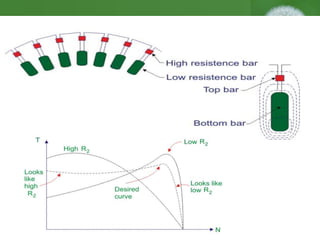

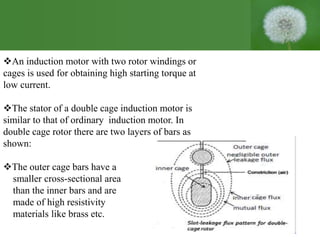

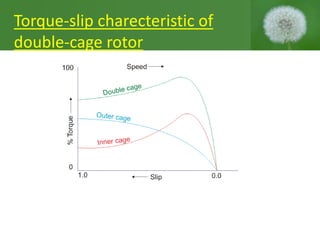

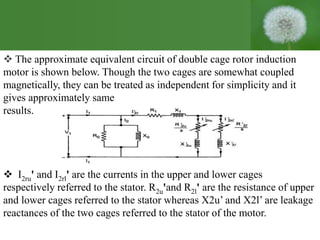

This document discusses the double cage induction motor. It aims to achieve high starting torque without affecting efficiency. This is done by using a rotor with two cages made of different materials - an outer cage of high resistivity material and an inner cage of low resistance material like copper. At start up, most current flows through the high resistance outer cage, providing high starting torque. During normal operation, current mostly flows through the low resistance inner cage, maintaining high efficiency. Some key applications mentioned are water pumps and machines like lathes and drills that require high starting torque.