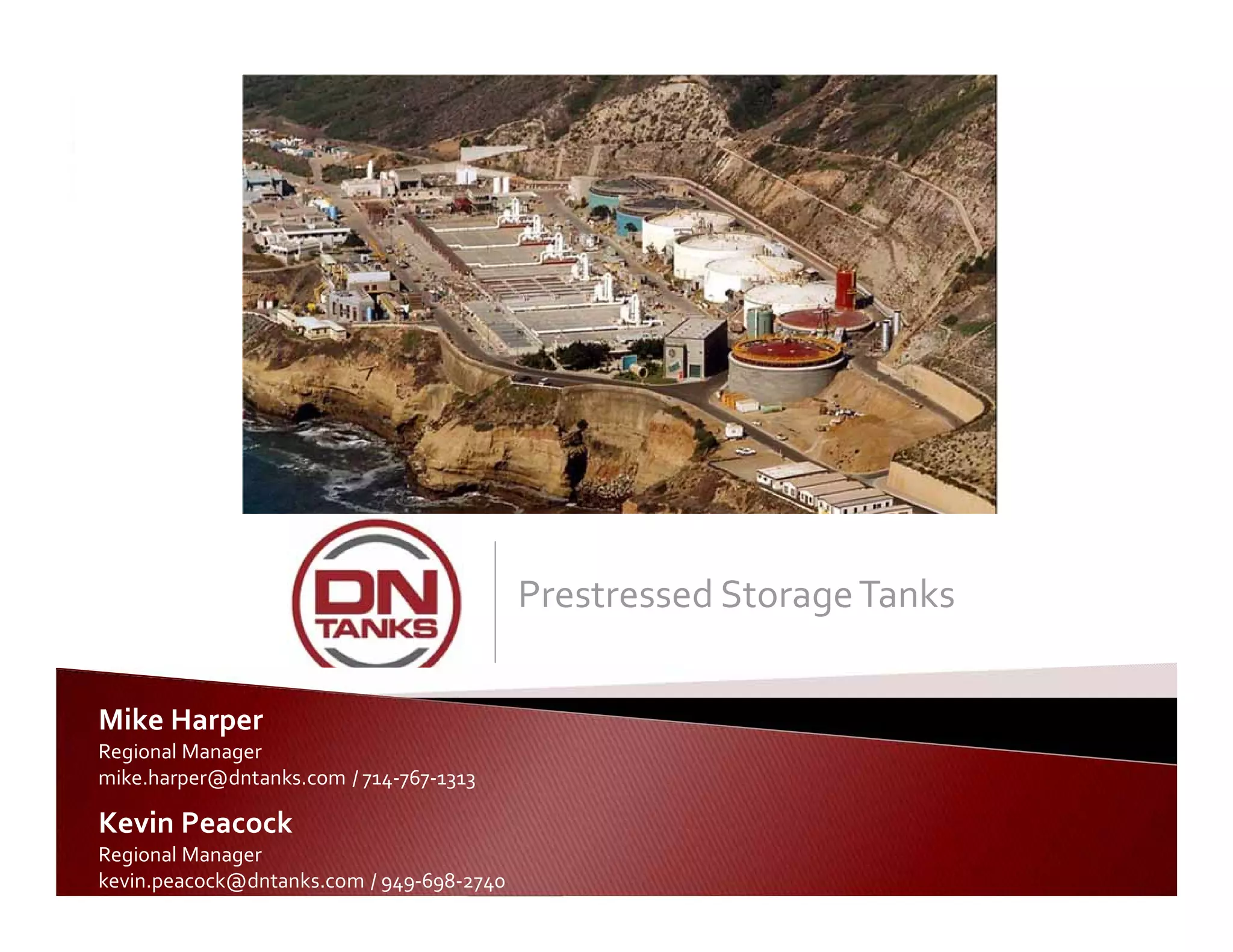

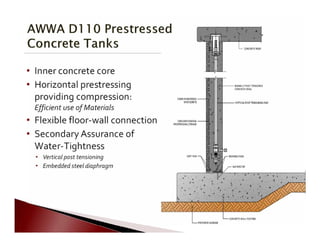

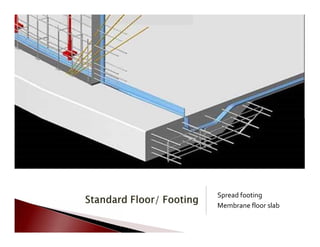

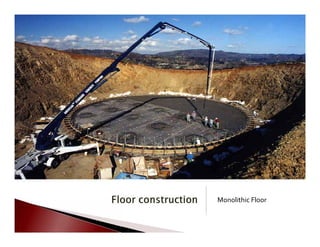

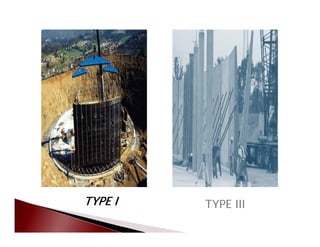

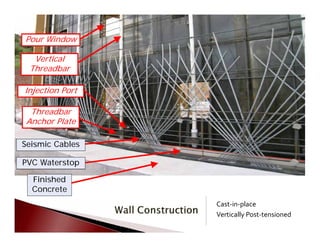

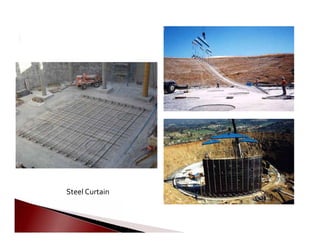

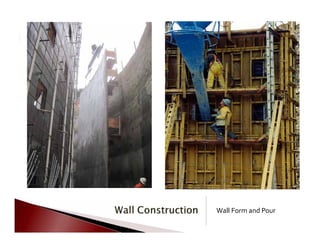

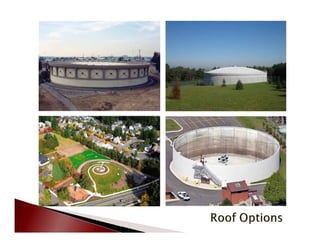

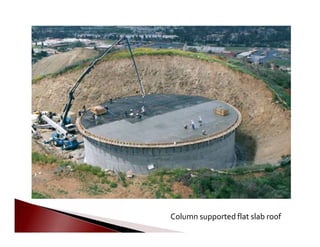

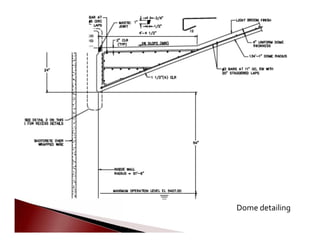

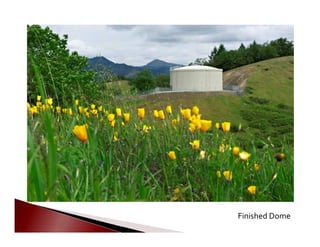

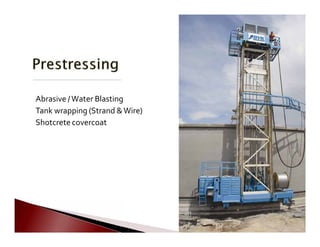

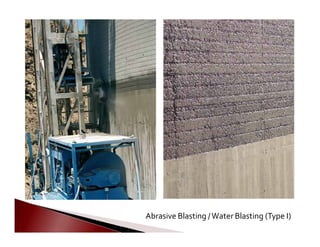

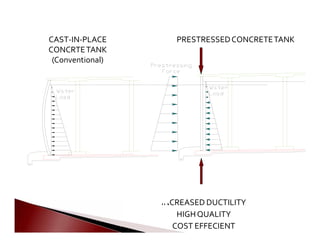

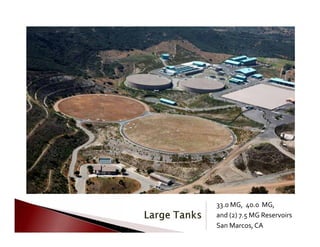

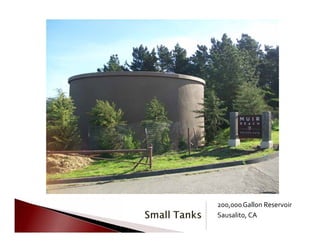

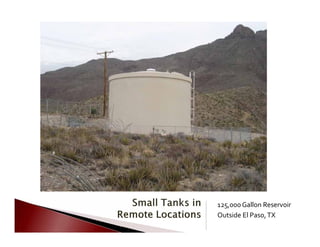

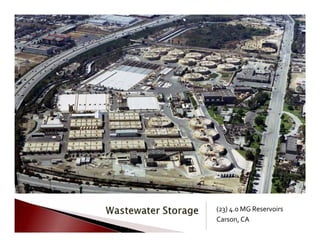

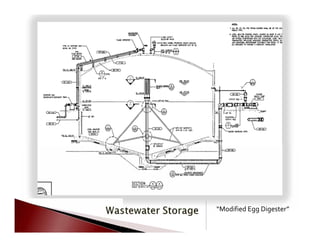

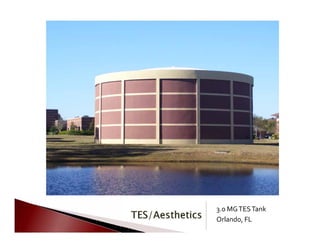

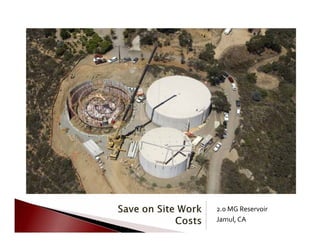

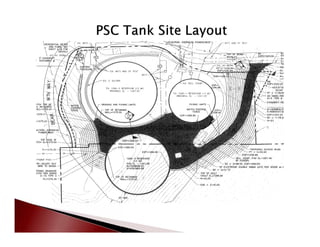

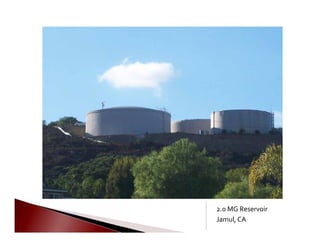

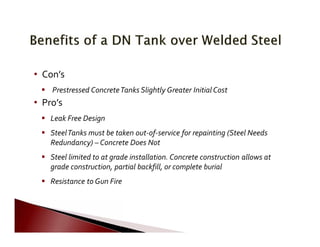

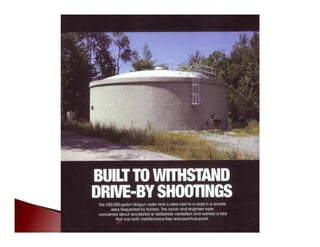

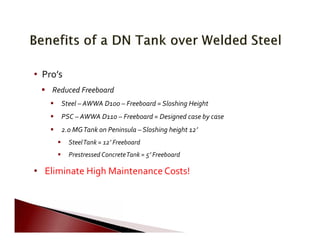

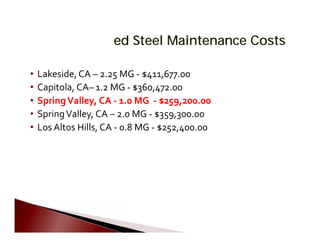

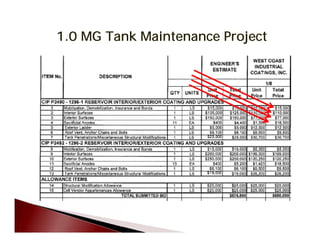

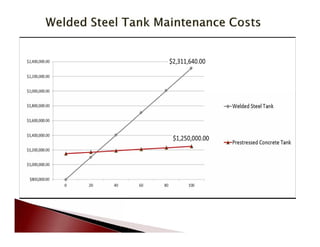

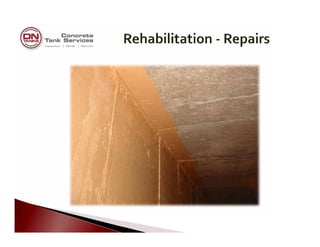

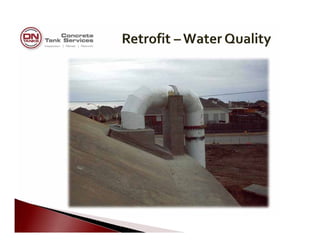

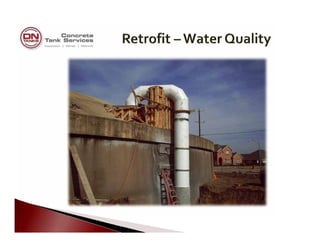

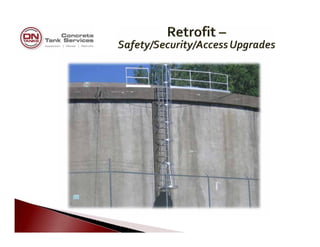

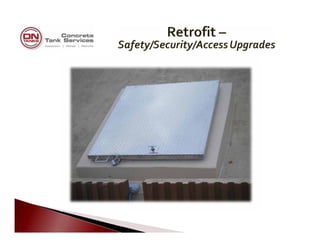

This document provides information about prestressed concrete storage tanks from DNTanks. It discusses DNTanks' construction procedures, the benefits of prestressed concrete tanks, and applications. DNTanks is the largest manufacturer of prestressed concrete tanks in the world, with over 130 years of combined experience constructing over 2,500 tanks globally. Prestressed concrete tanks provide benefits like being leak-free, requiring less maintenance than steel tanks, and allowing various installation methods. The document also discusses inspection and retrofitting of existing concrete tanks.