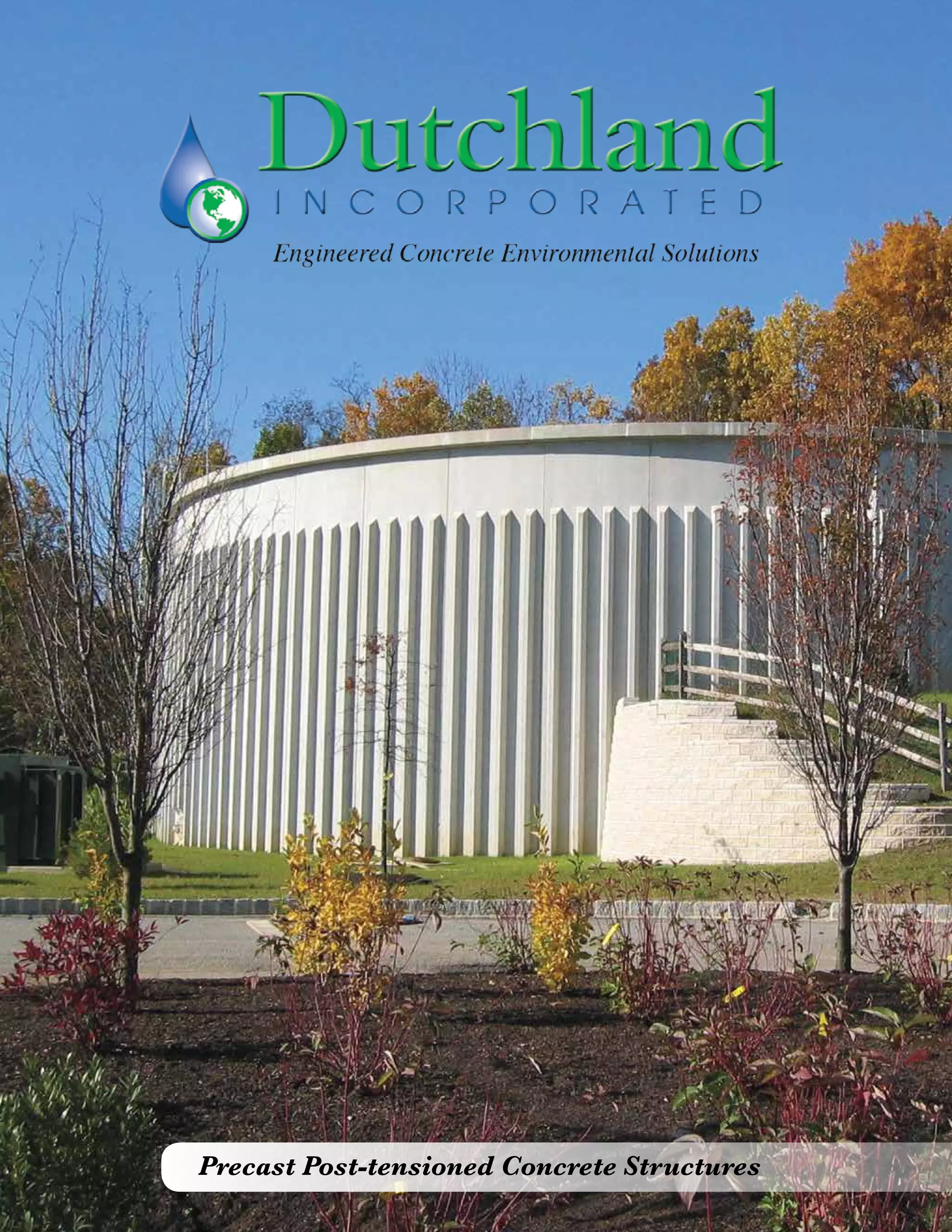

Dutchland, Inc. is a precast concrete manufacturer that specializes in post-tensioned concrete structures using certified personnel. They produce tanks for water storage and wastewater treatment that are virtually maintenance-free for decades, requiring minimal site space and less construction time compared to cast-in-place. All structures are warranted for 10 years and can be constructed above or below ground in various configurations to meet specific needs.