This 3-sentence summary provides the key details about the industrial training report:

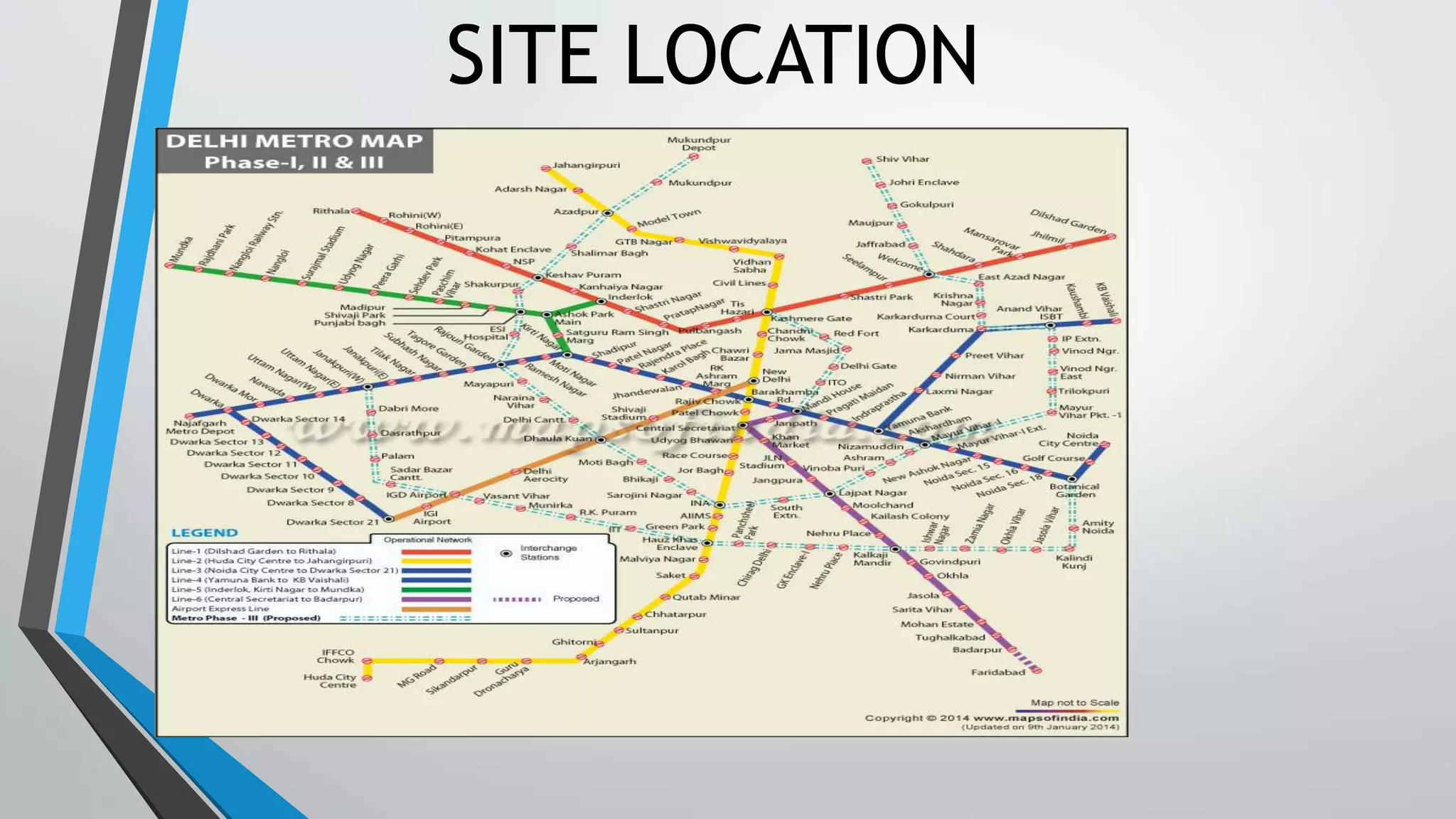

The report discusses MD. Shadab's 10-day industrial training at Delhi Metro Rail Corporation from July 10th to August 10th, where he learned about tunnel construction, safety protocols, waterproofing techniques, and concrete work methods used in metro tunneling projects. Key aspects covered included the use of TBMs to construct twin tunnels over 5 meters in diameter, safety equipment like helmets and gloves, applying waterproofing membranes, and placing and curing concrete for tunnel infrastructure.