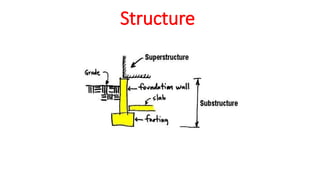

Site selection and site plan

Foundation and basements

Masonry, Brick masonry, Stone masonry, Concrete hollow block masonry

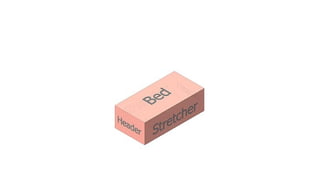

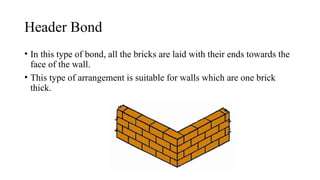

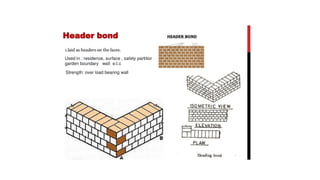

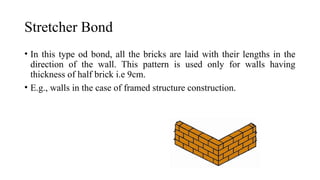

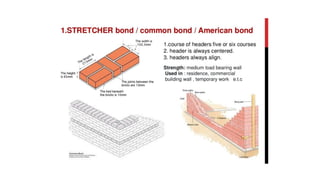

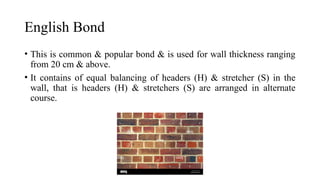

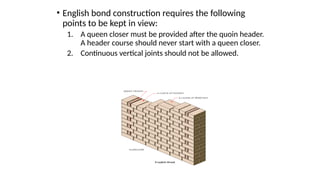

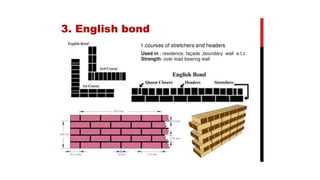

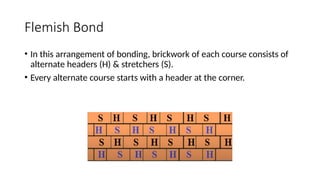

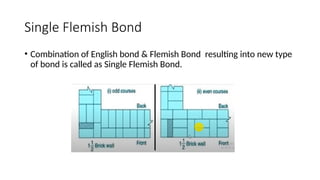

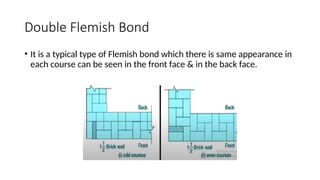

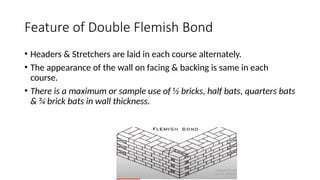

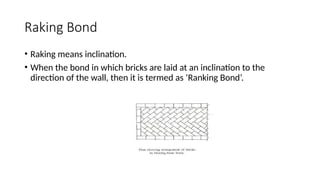

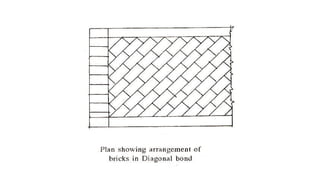

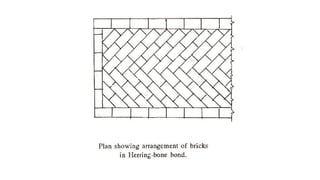

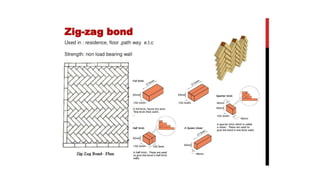

Bonds

Precast paver blocks

Flooring, Construction joints, Movement and expansion joints, Contraction joints

Form works, Centering and shuttering, slip forms, Scaffoldings, shoring and underpinning

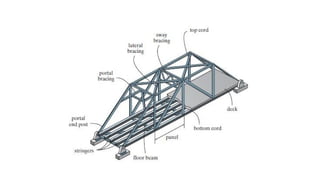

Fabrication and erection of trusses,

Acoustics, Sound insulation, Fire protection

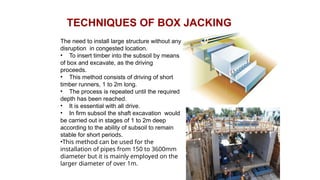

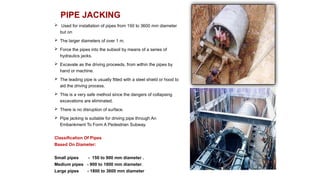

Box jacking, Pipe jacking, Arch jacking

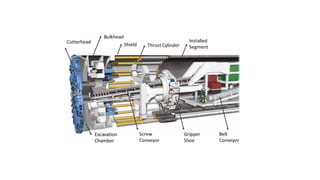

Tunnelling techniques

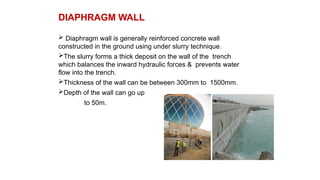

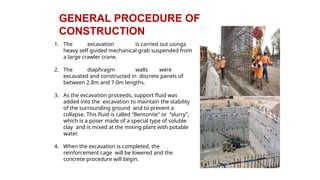

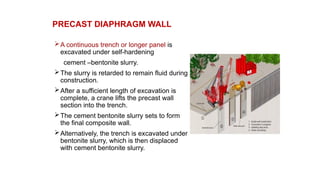

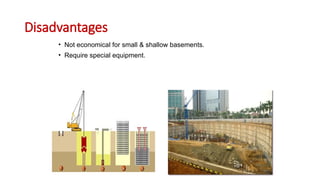

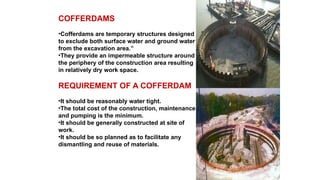

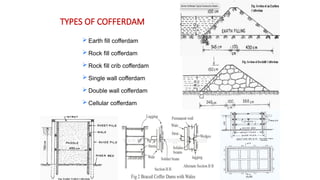

Underground and underwater diaphragm walls, Piling techniques

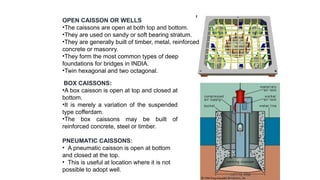

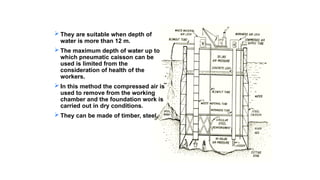

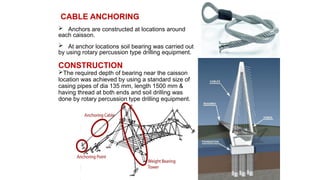

Well foundation and caisson

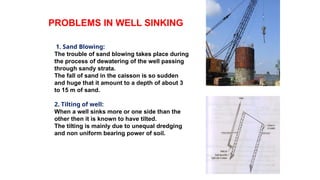

Sinking operations

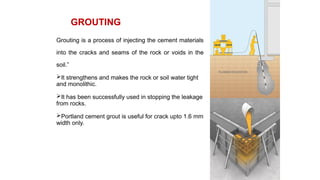

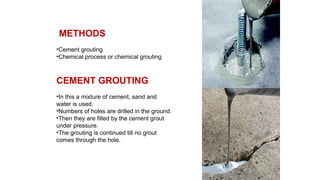

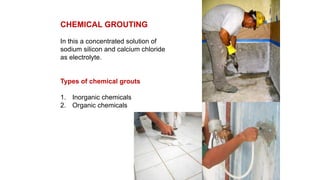

Cable anchoring and grouting

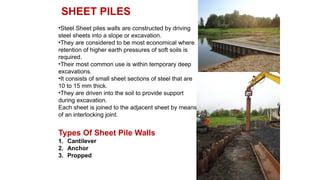

Sheet piling

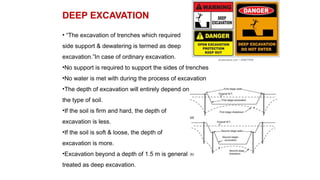

shoring for deep cutting

Dewatering techniques and pumping equipment

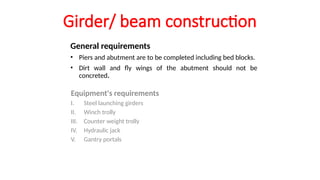

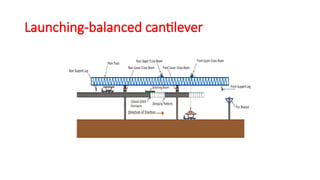

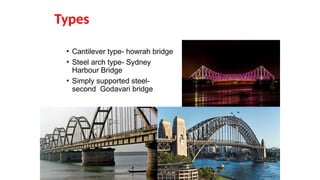

Launching girders

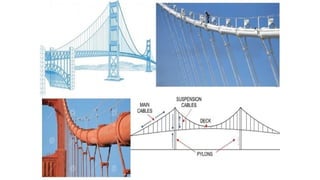

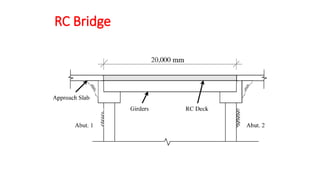

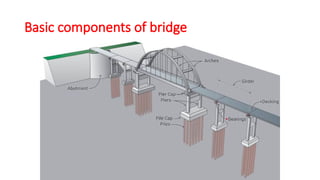

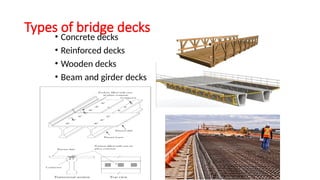

Bridge decks,

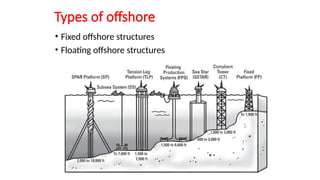

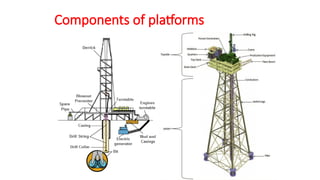

Offshore platforms

Special forms of the shells & domes

Techniques for heavy decks, In-situ prestressing in high rise structures

Material handling and erecting light weight components on tall structures

Articulated structures

Braced domes

Space decks