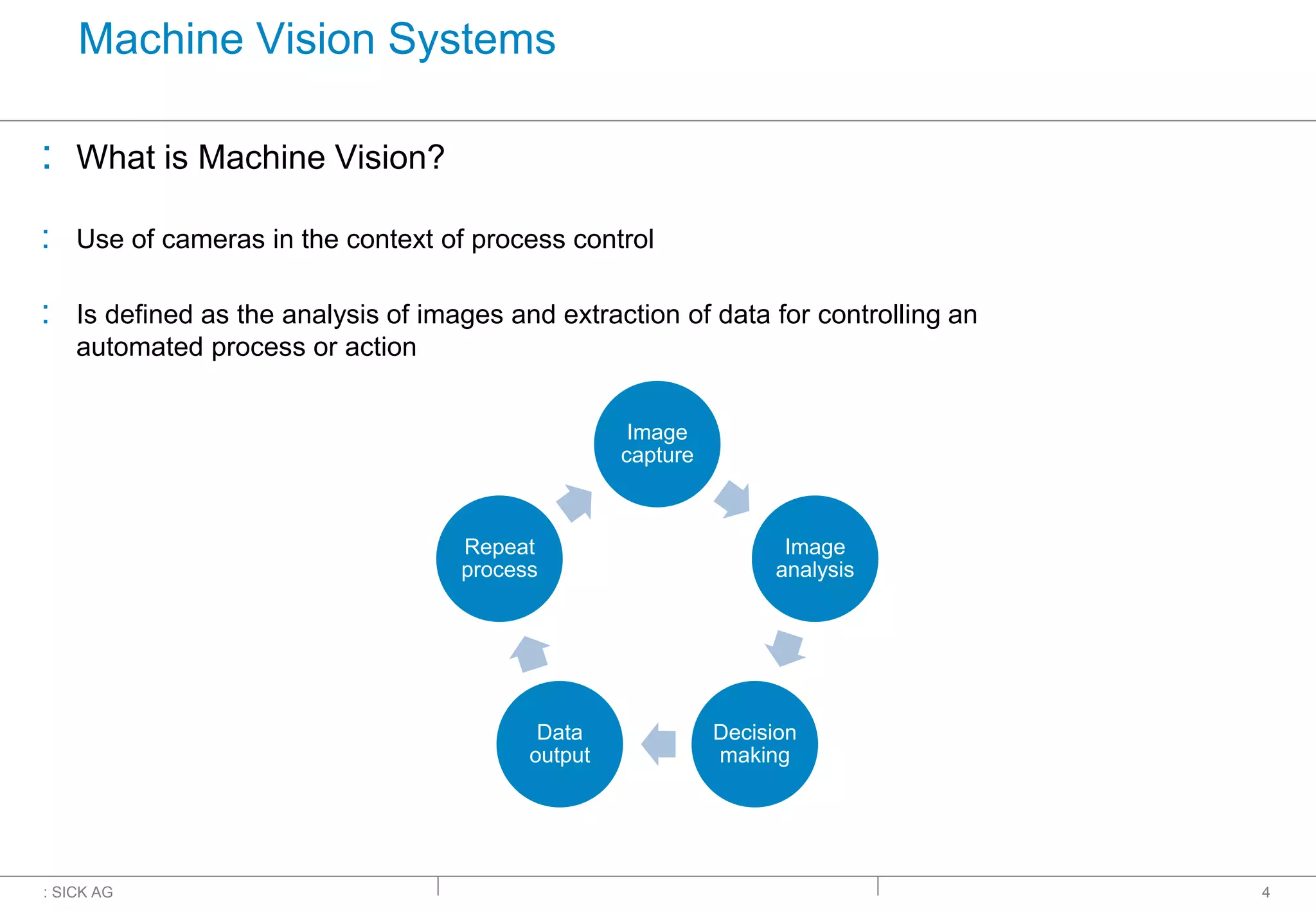

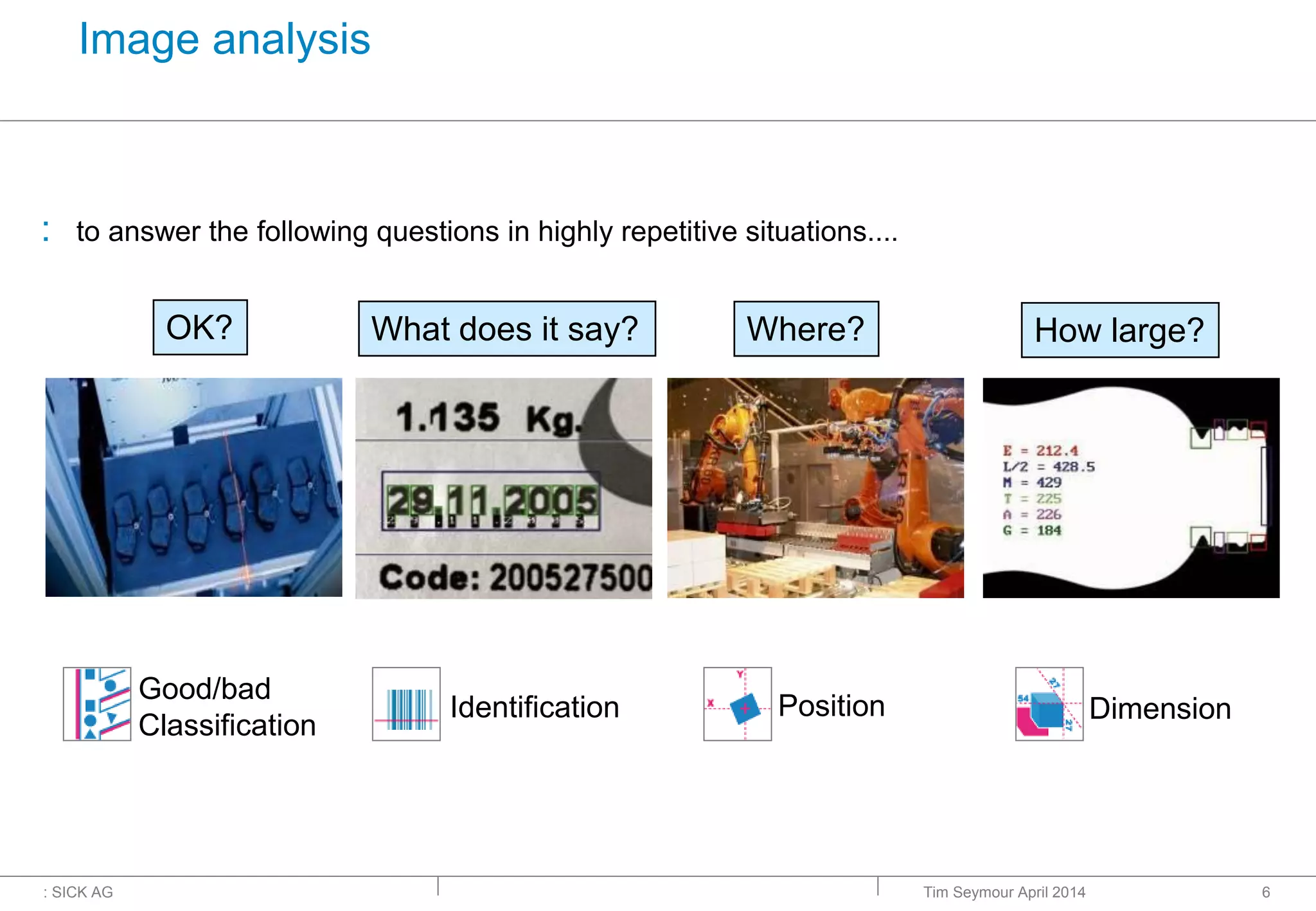

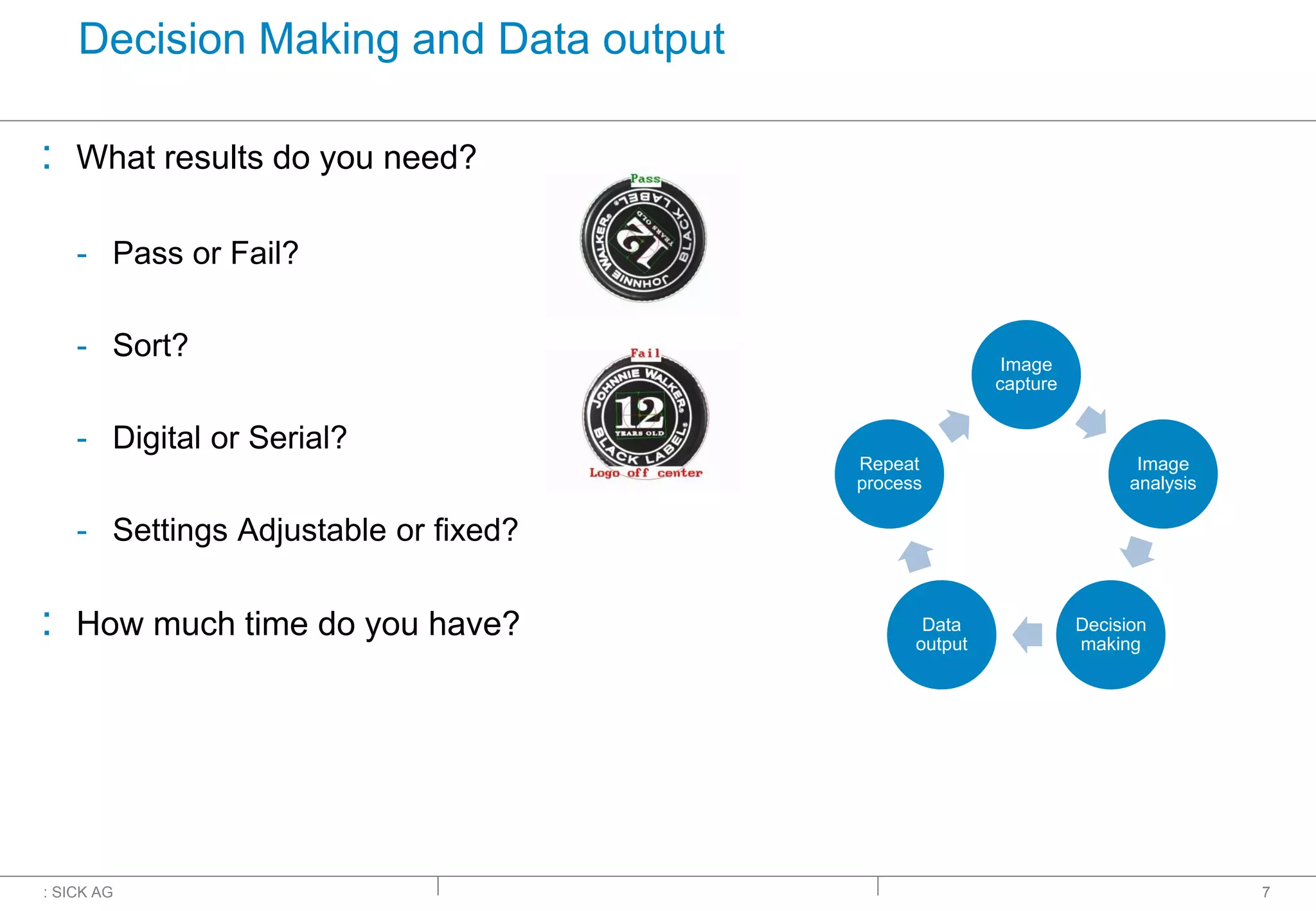

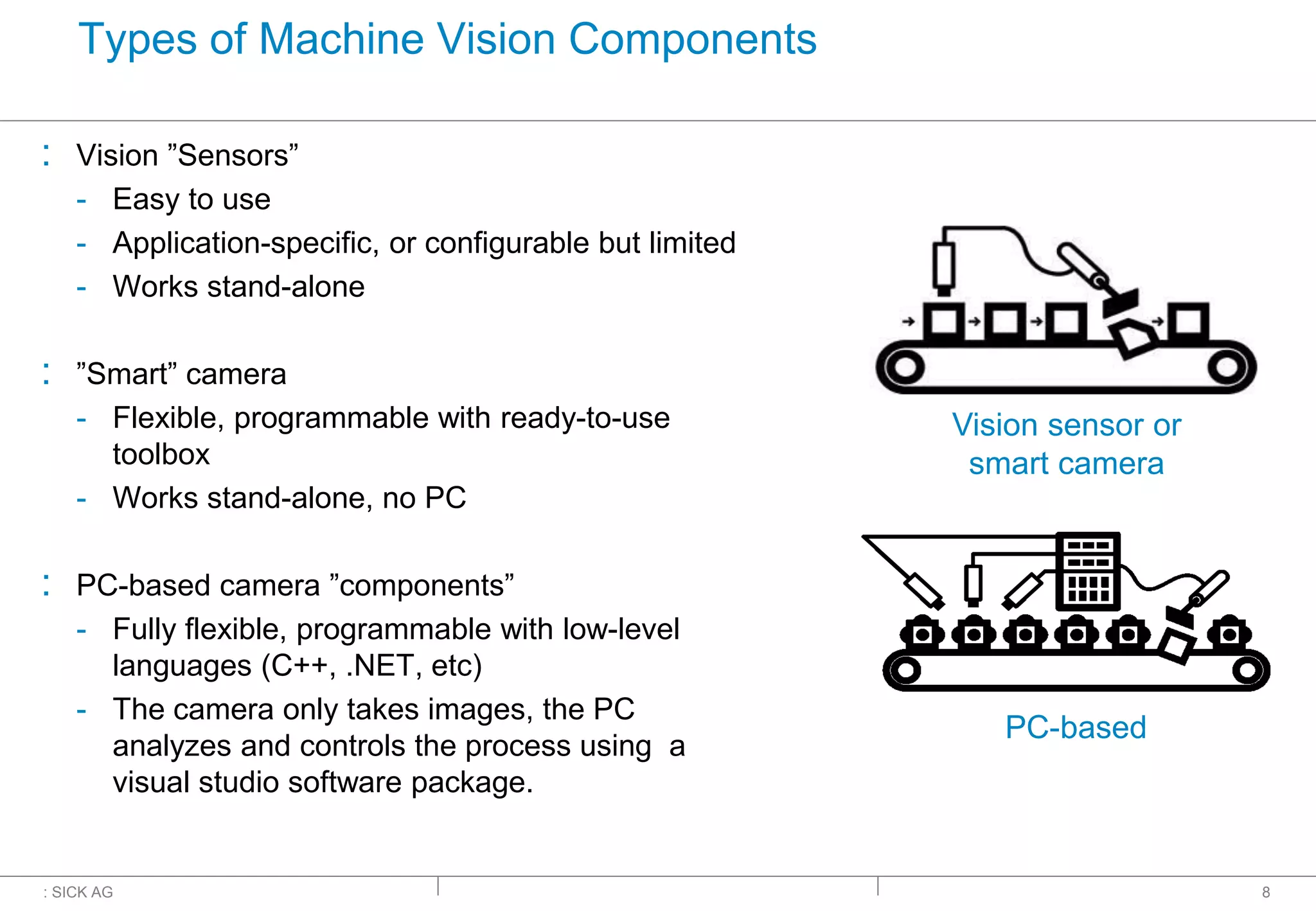

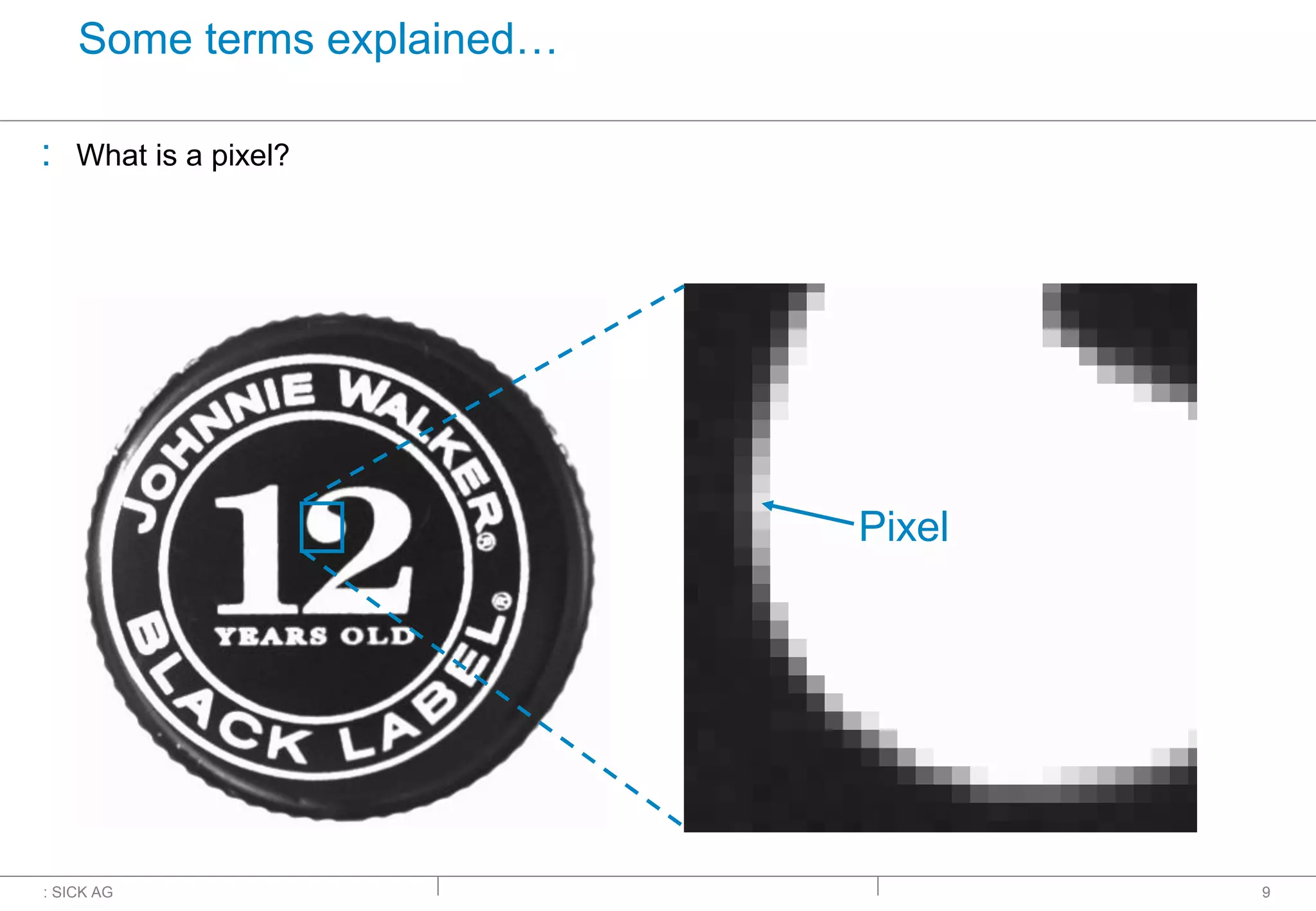

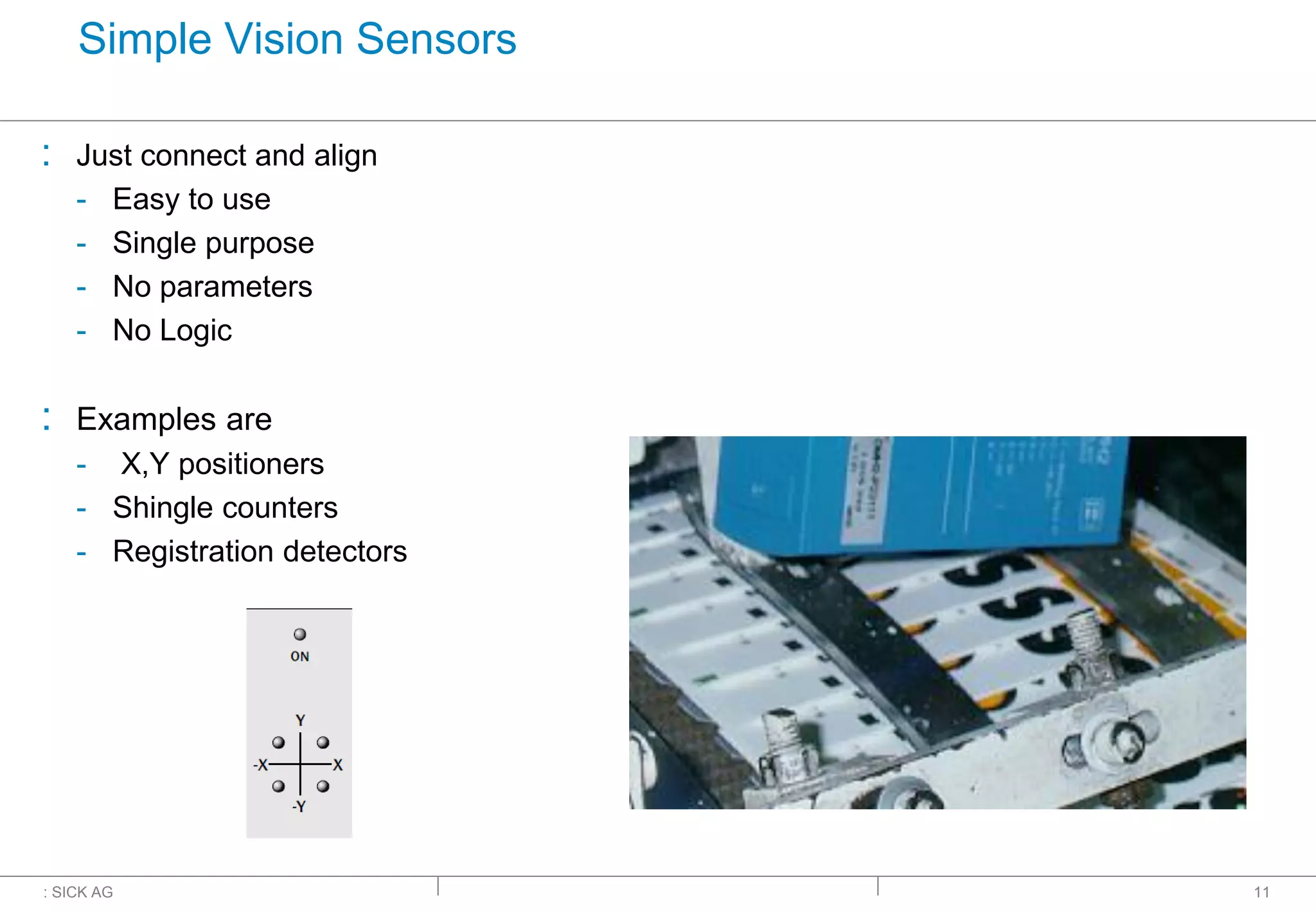

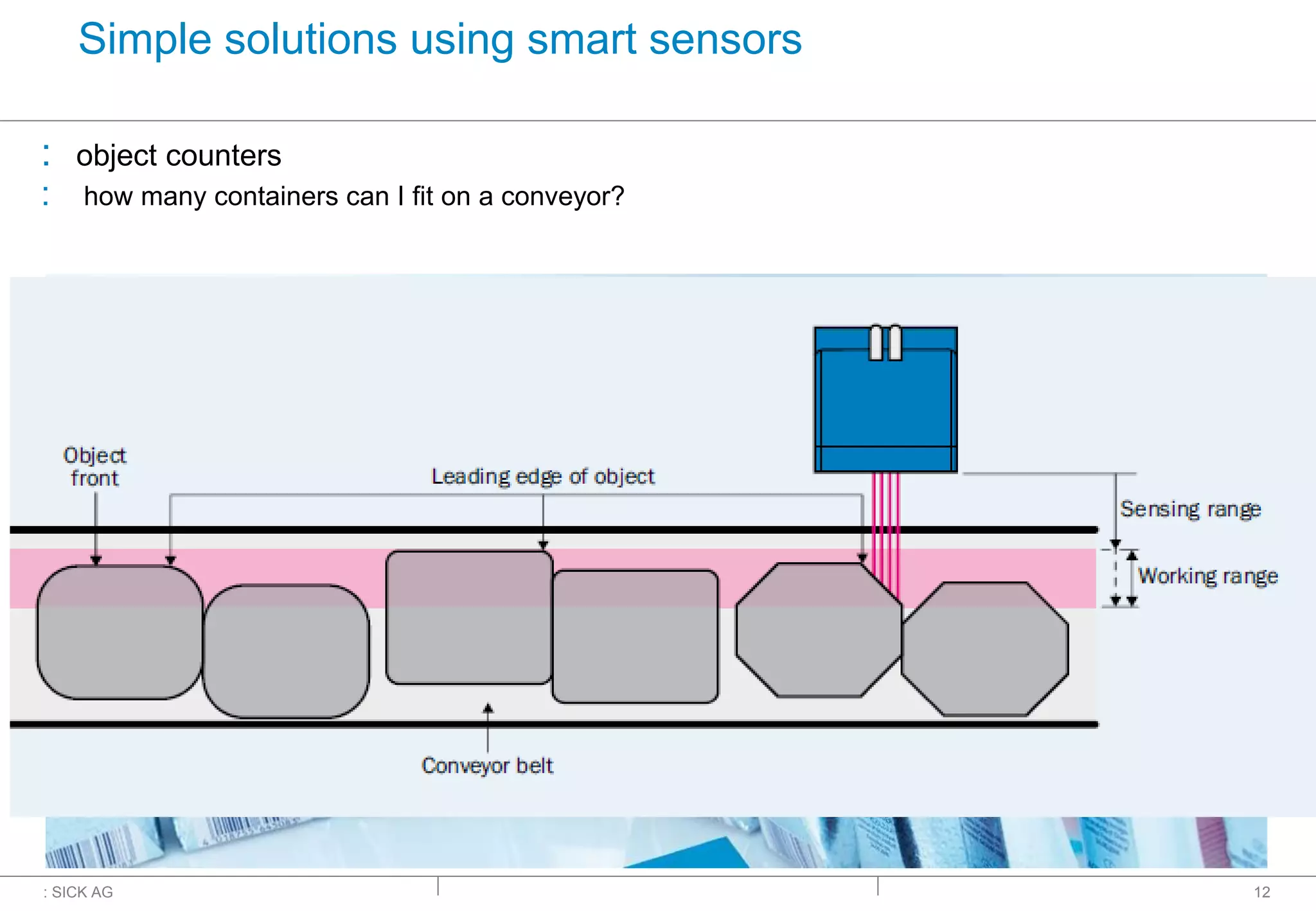

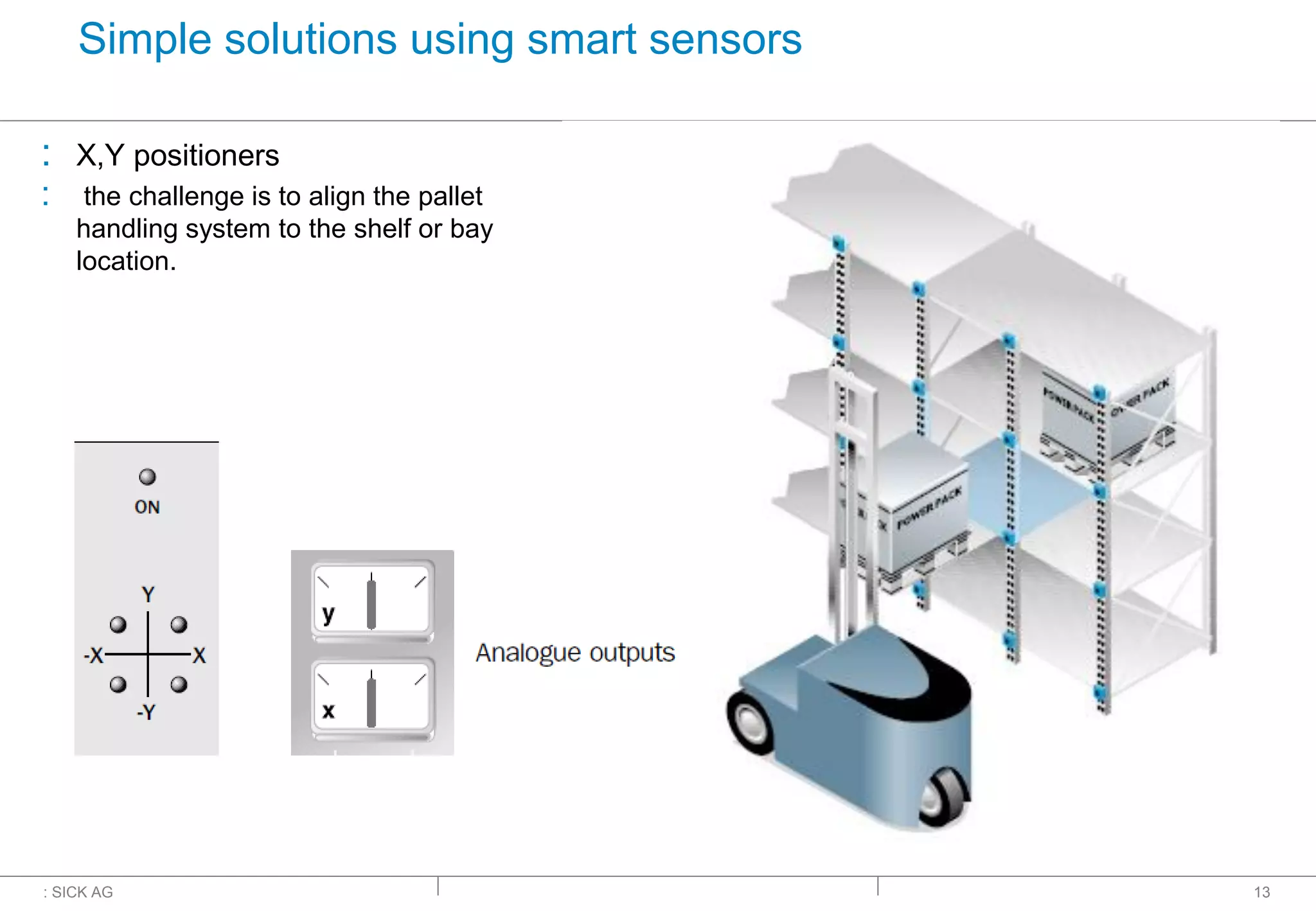

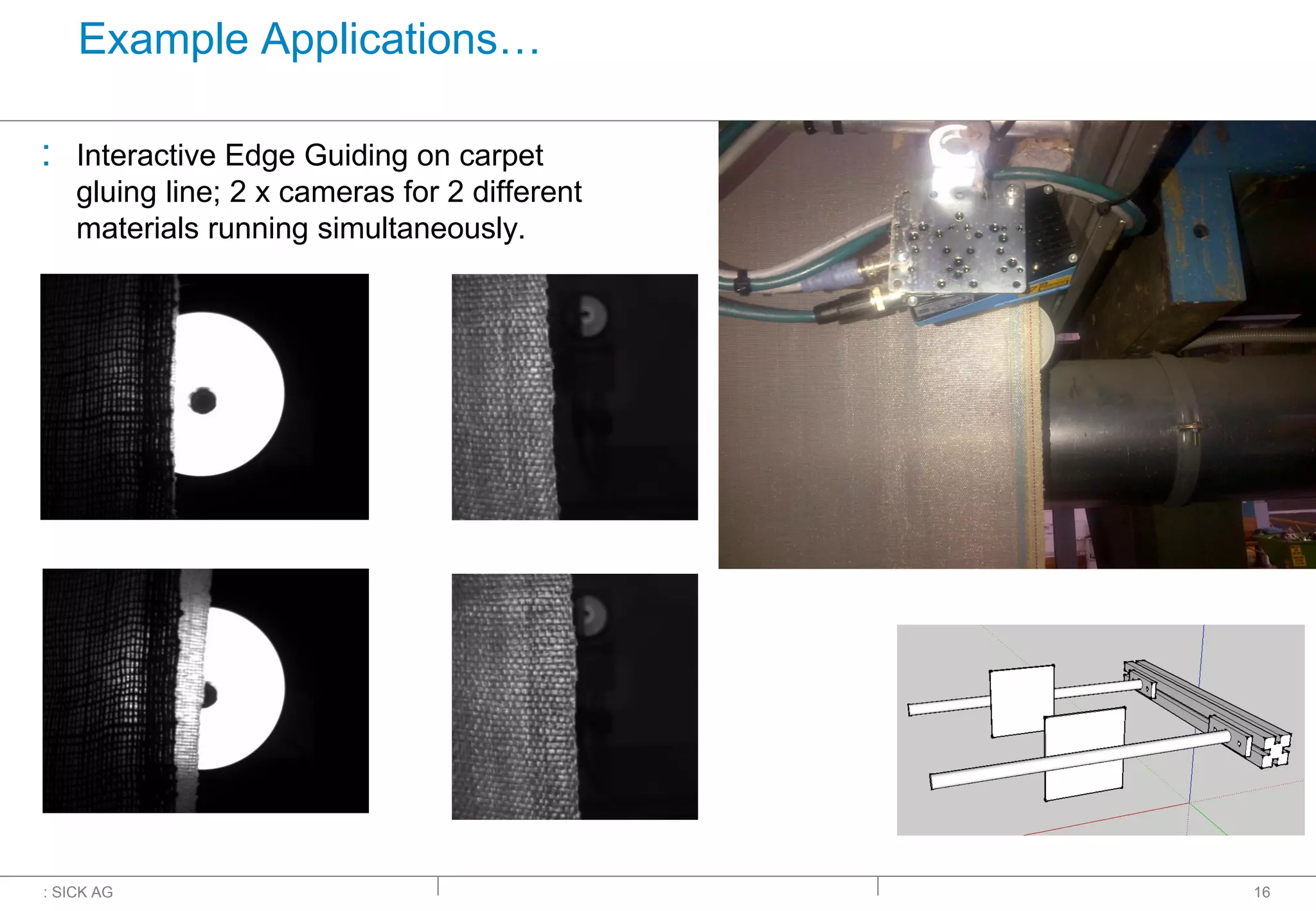

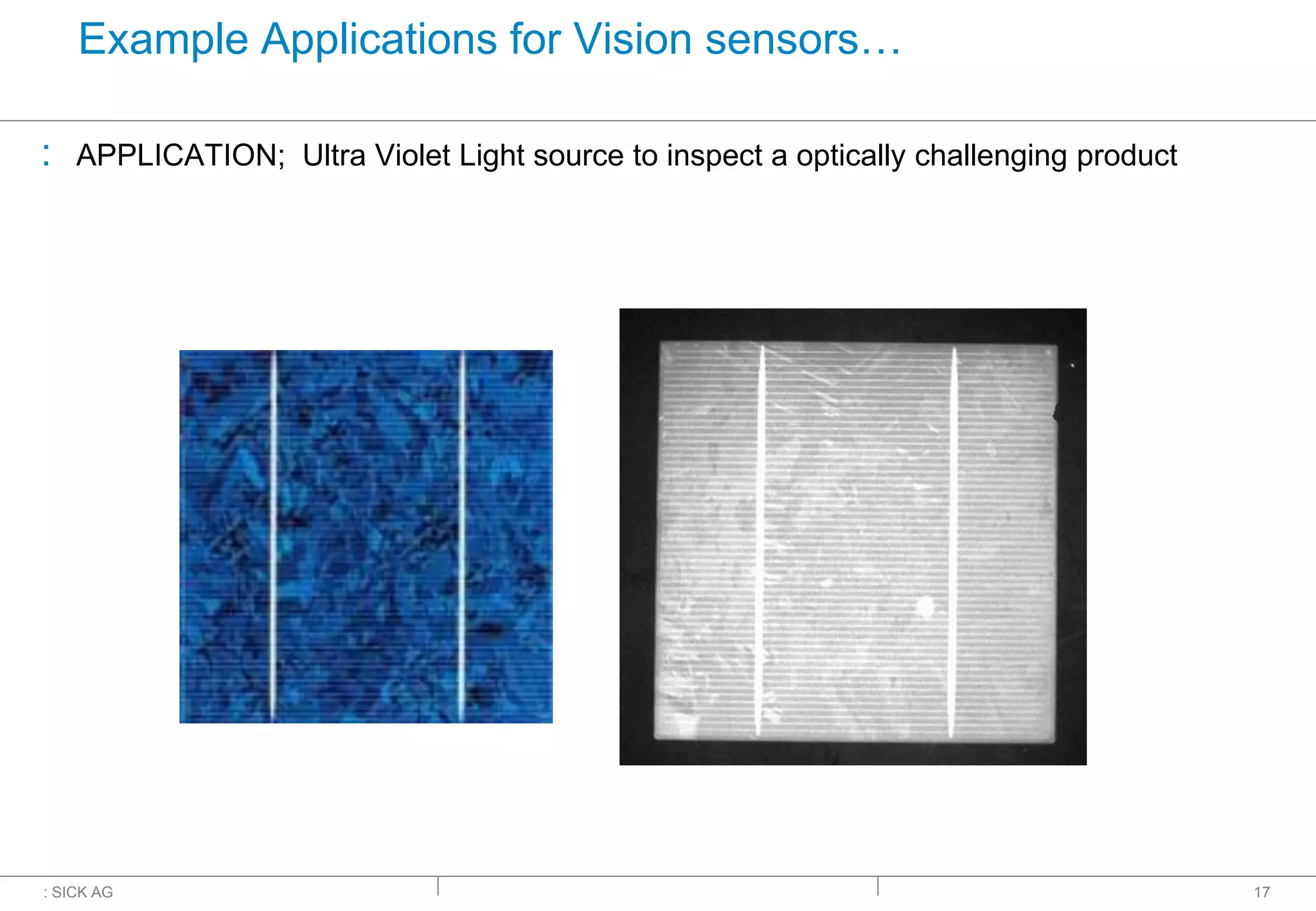

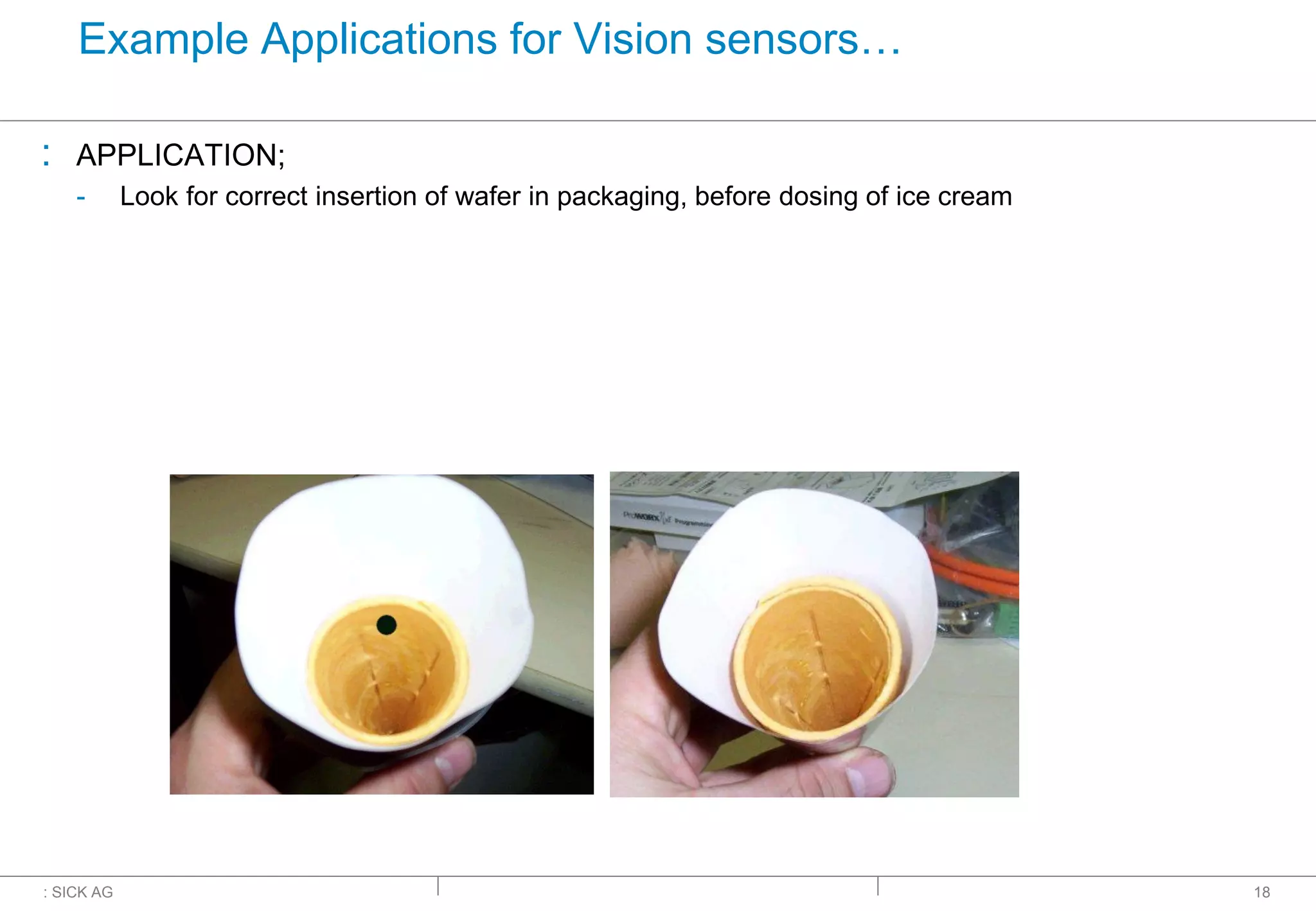

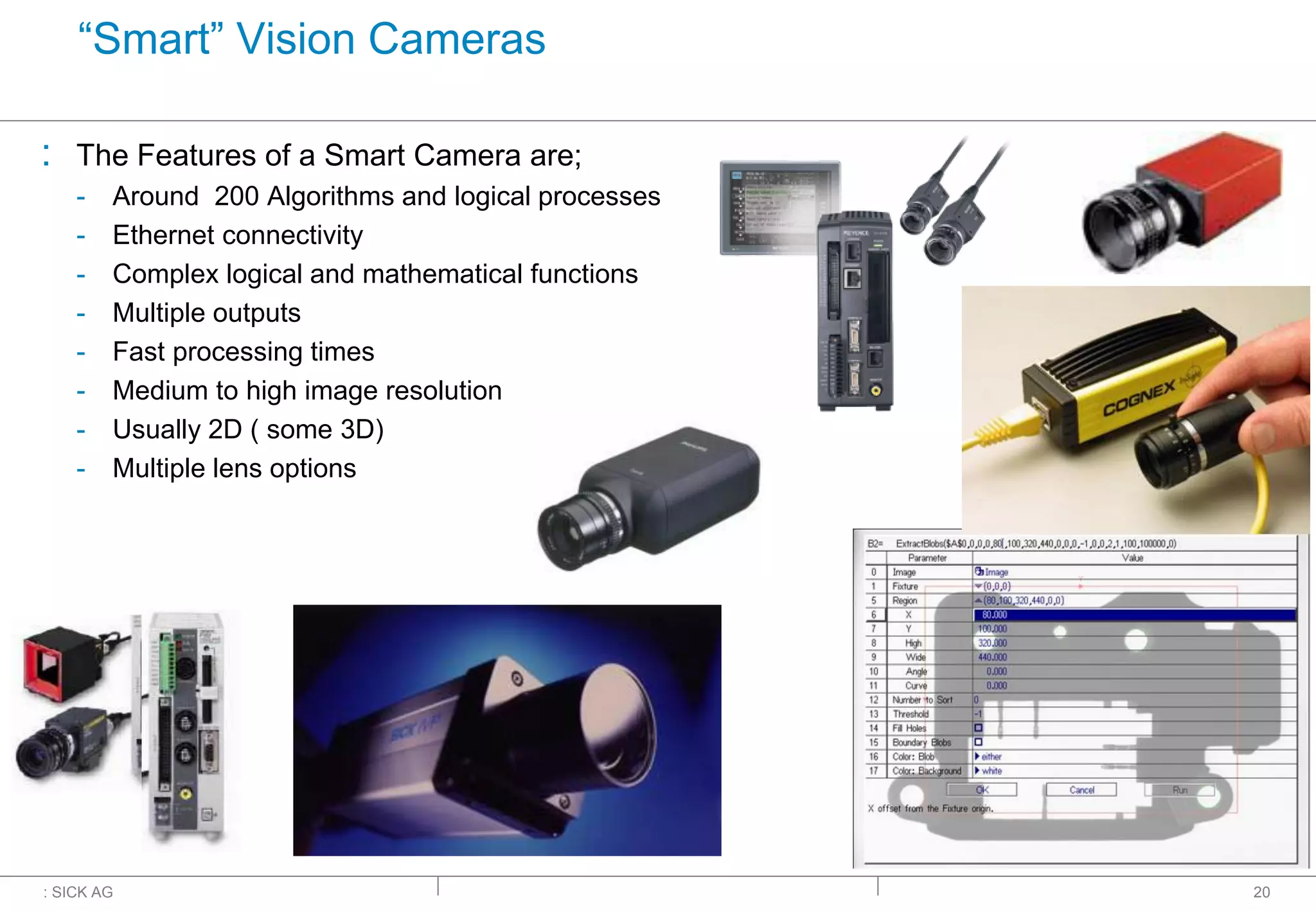

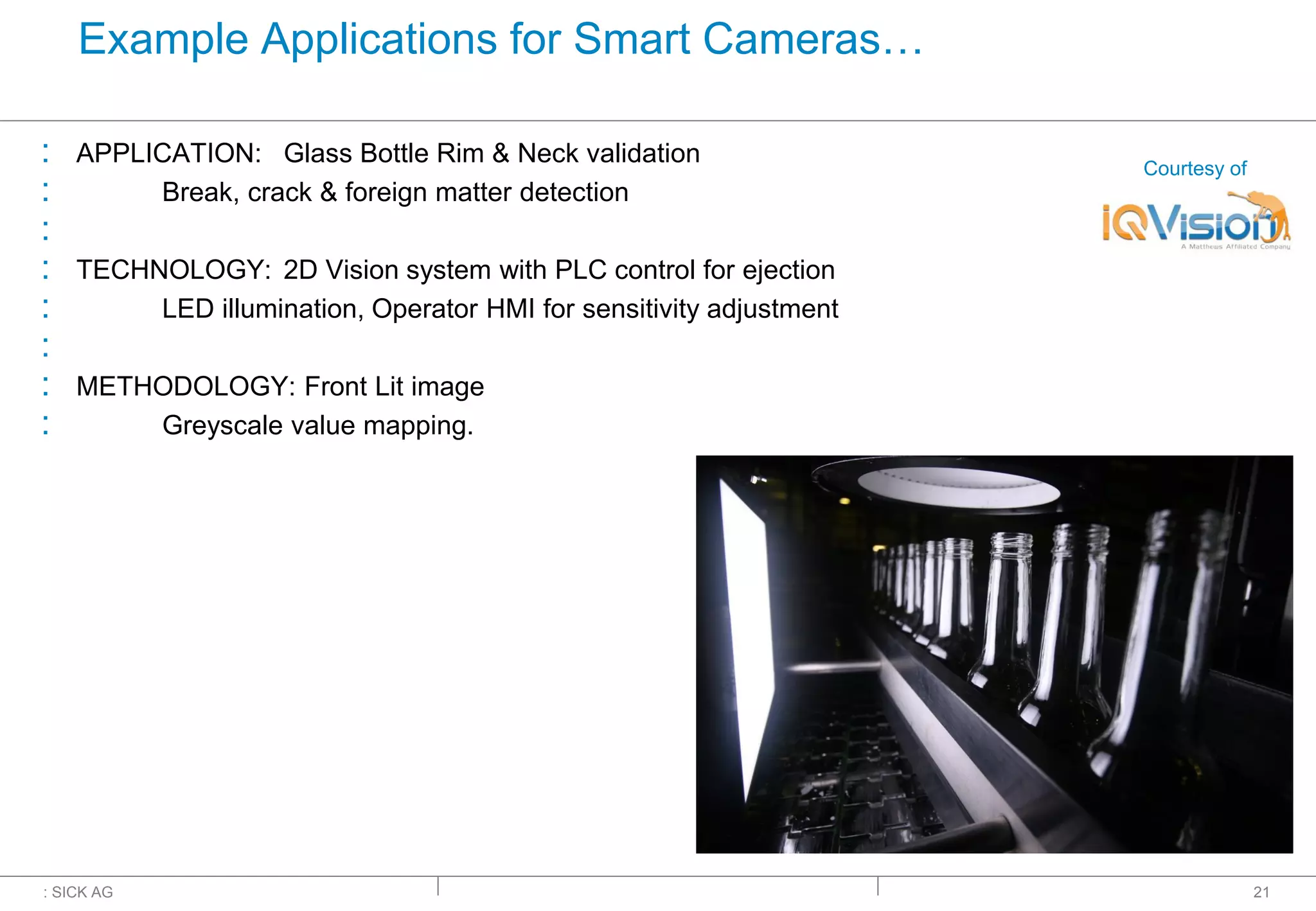

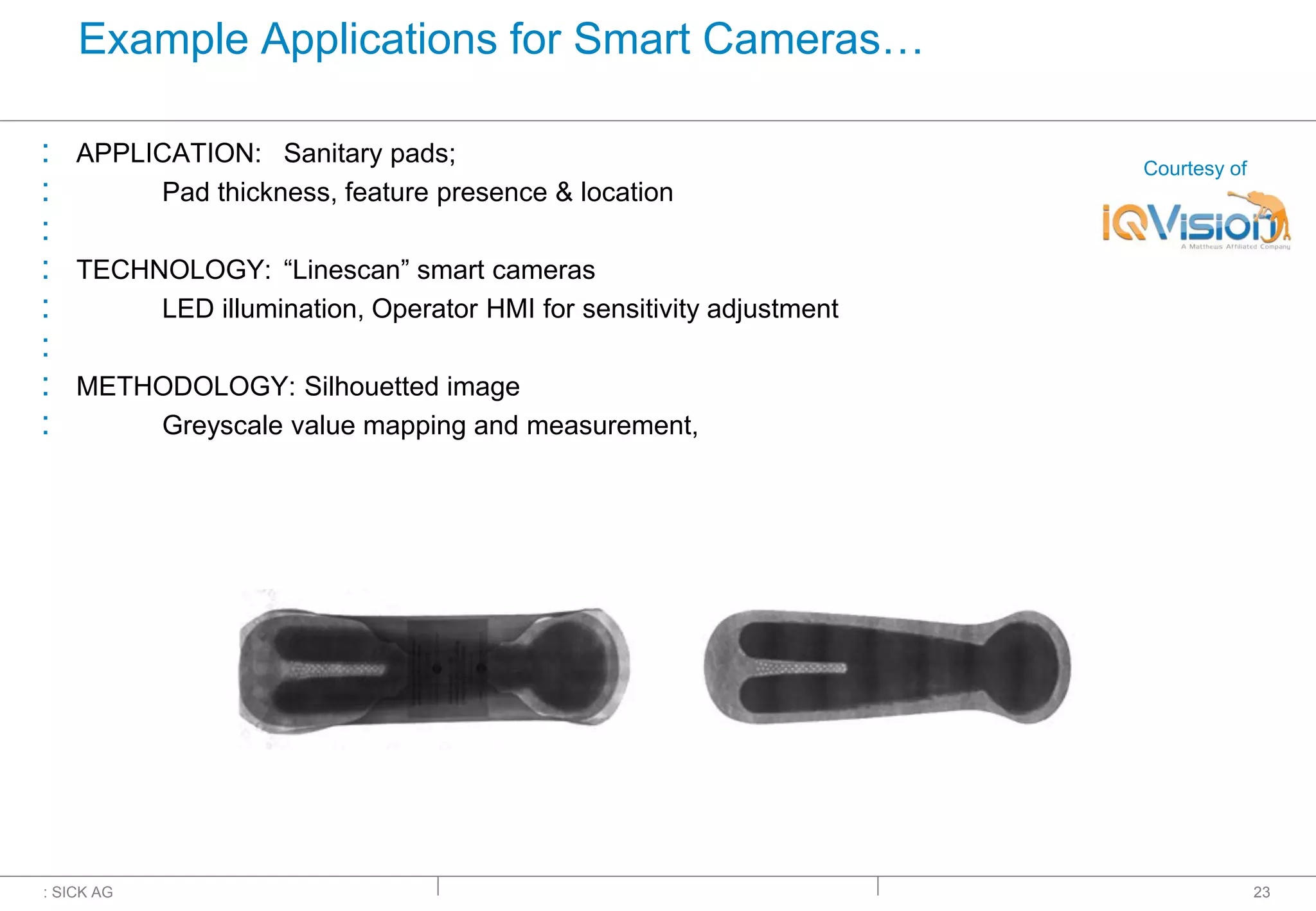

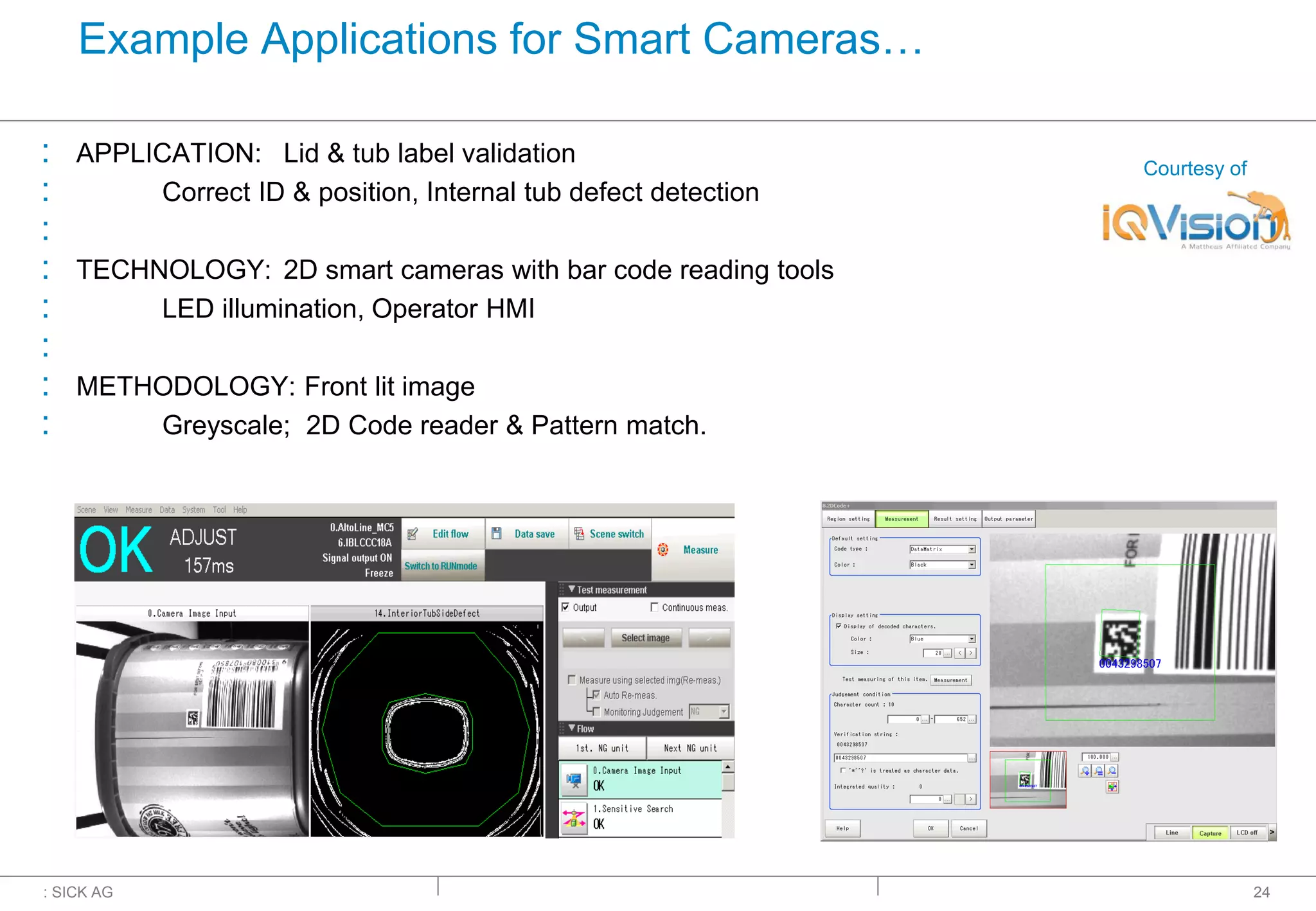

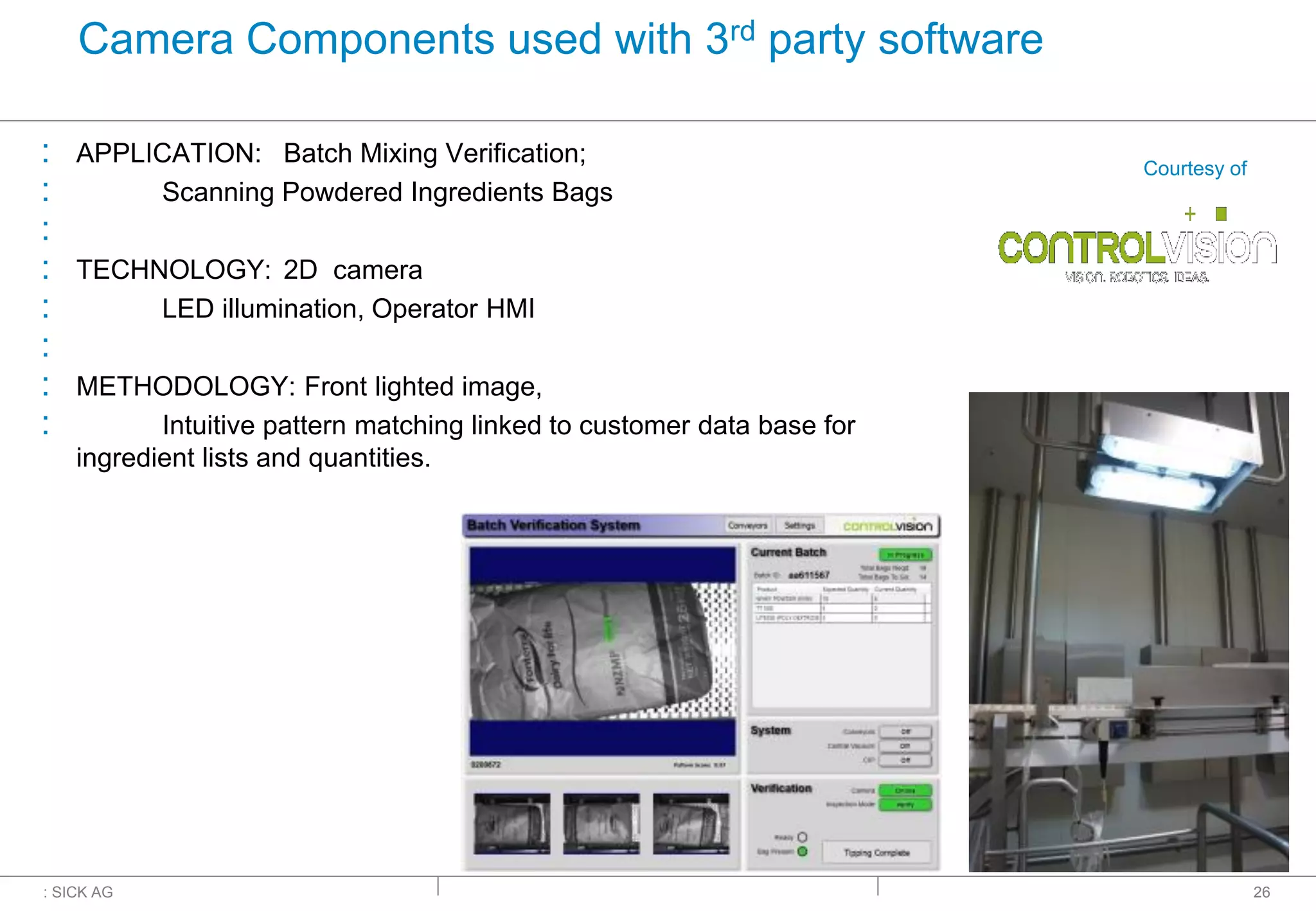

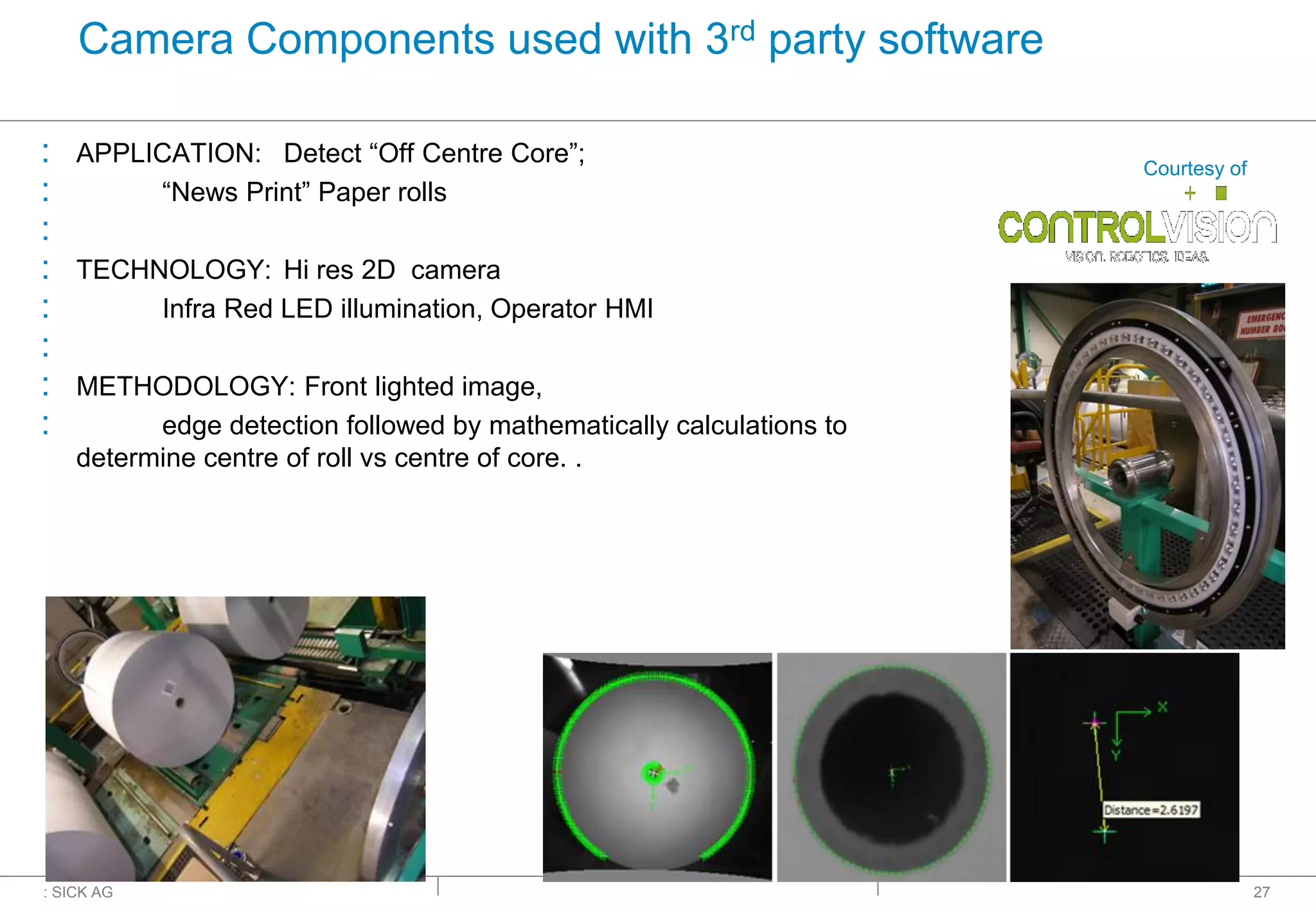

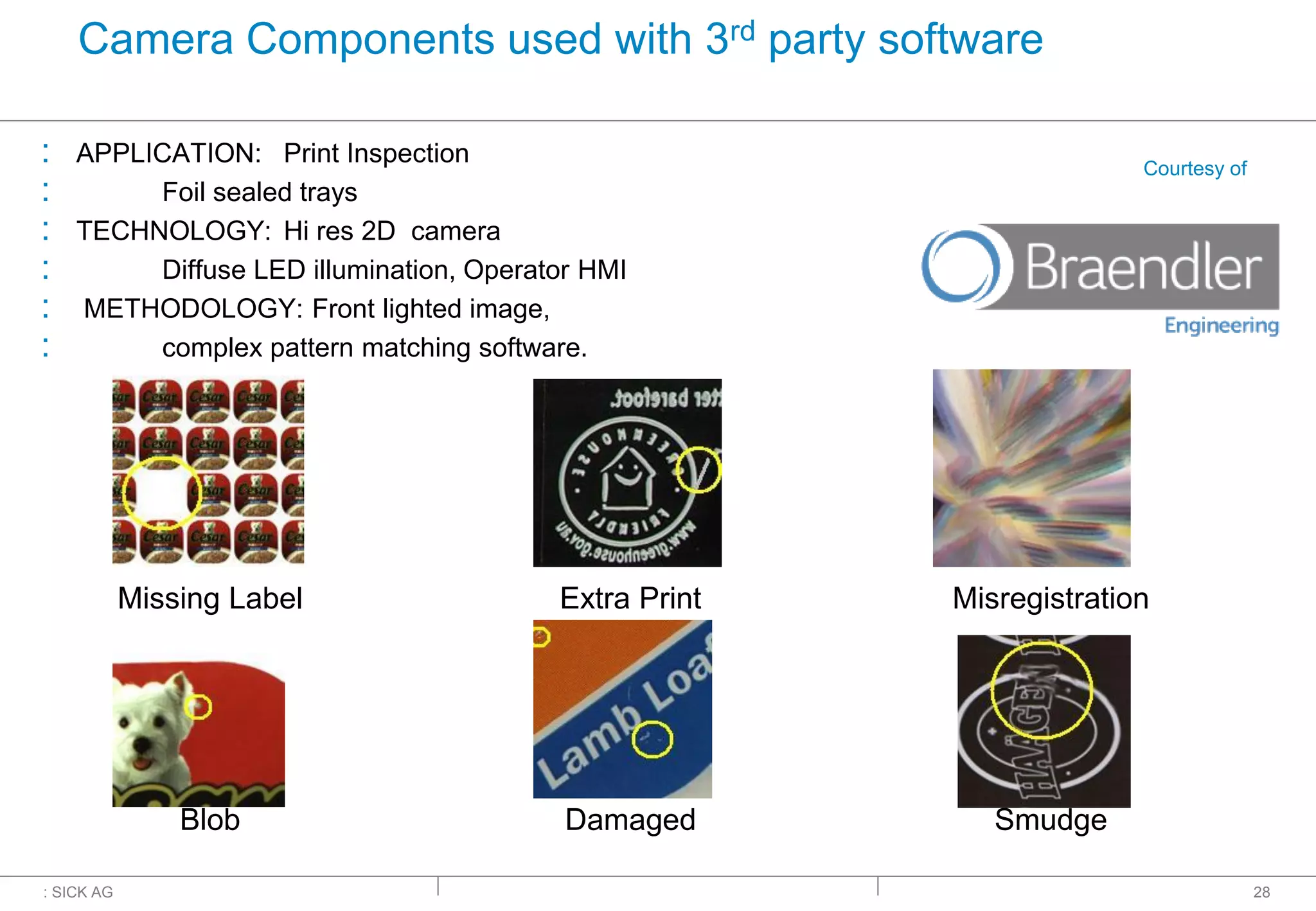

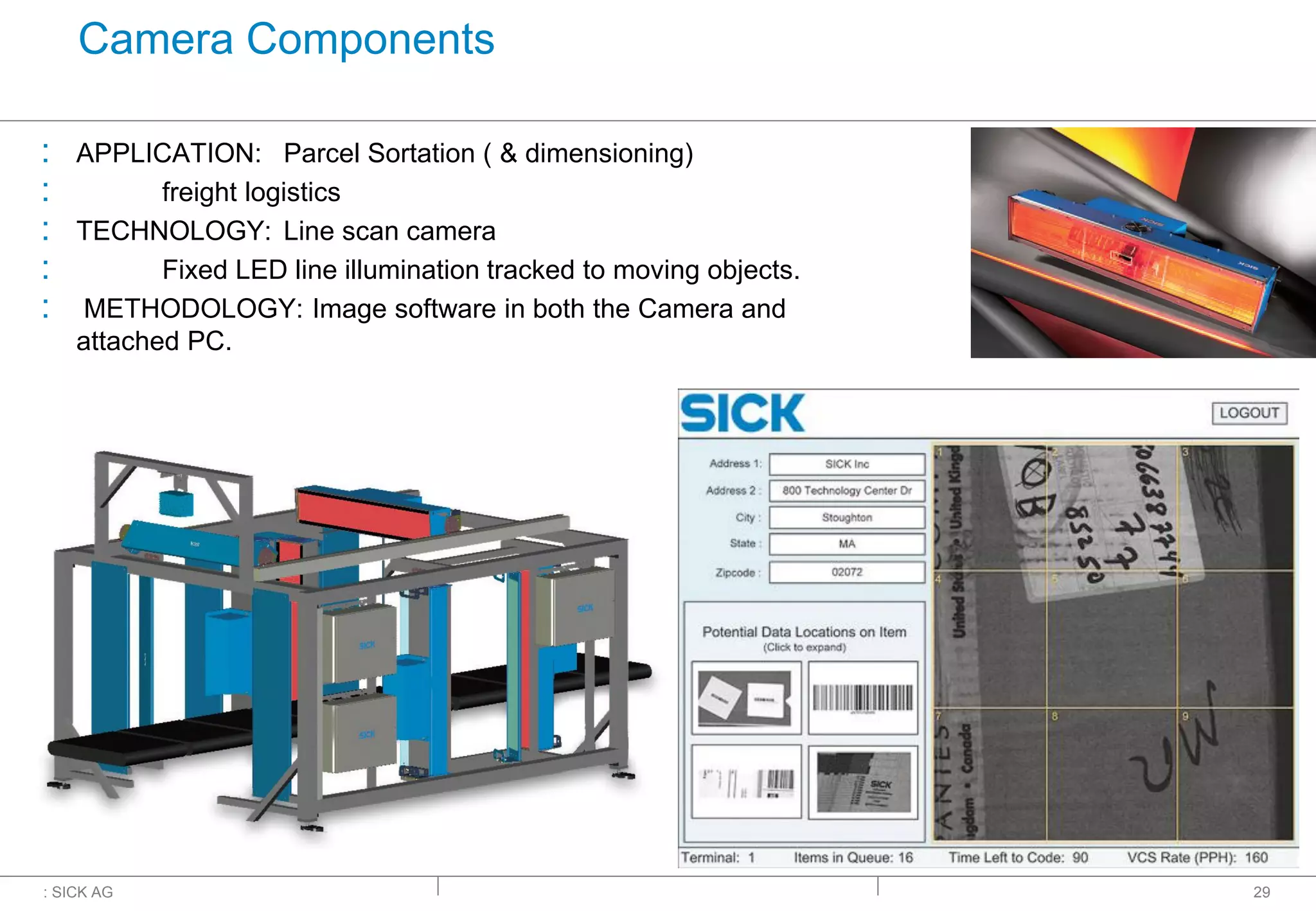

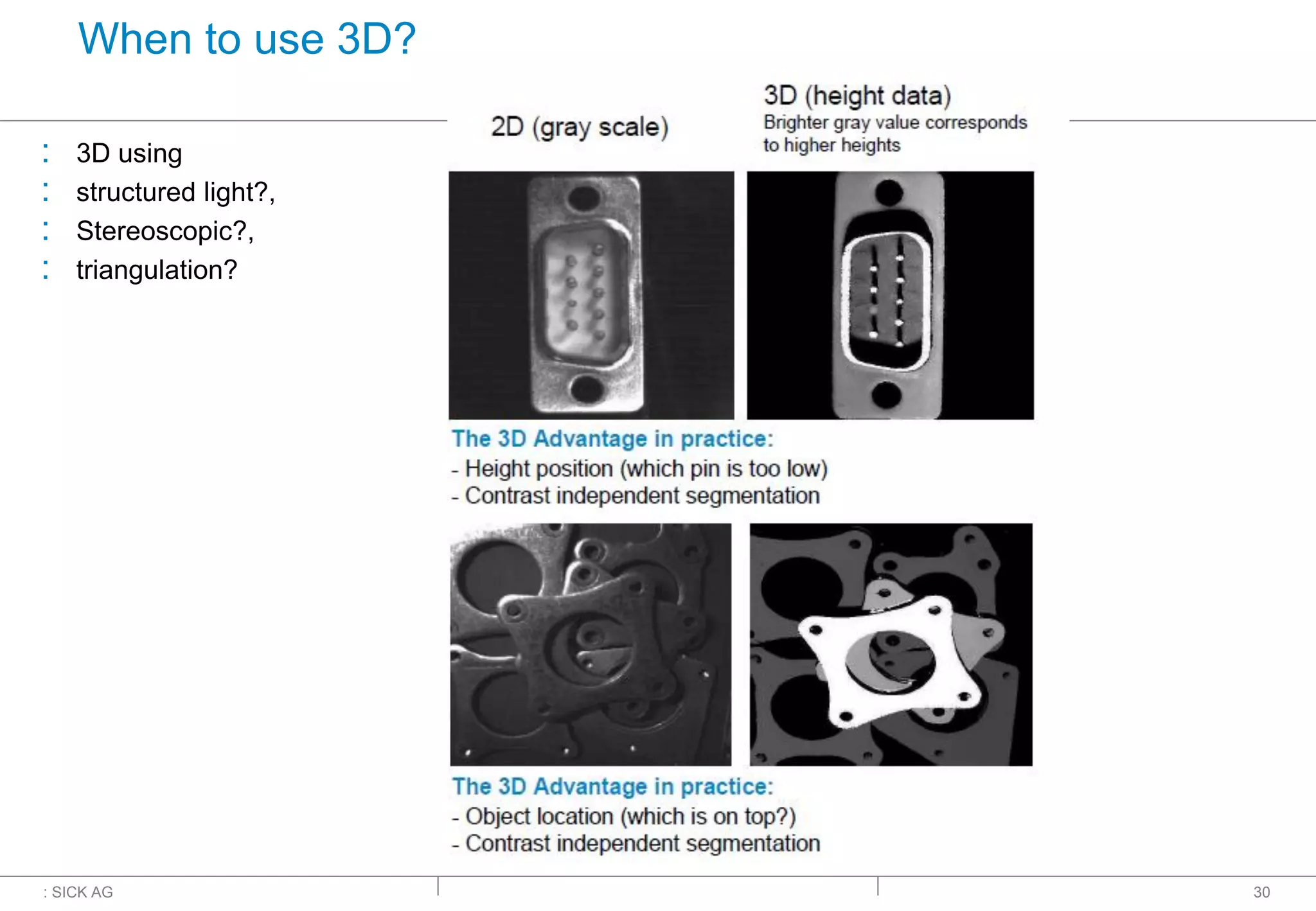

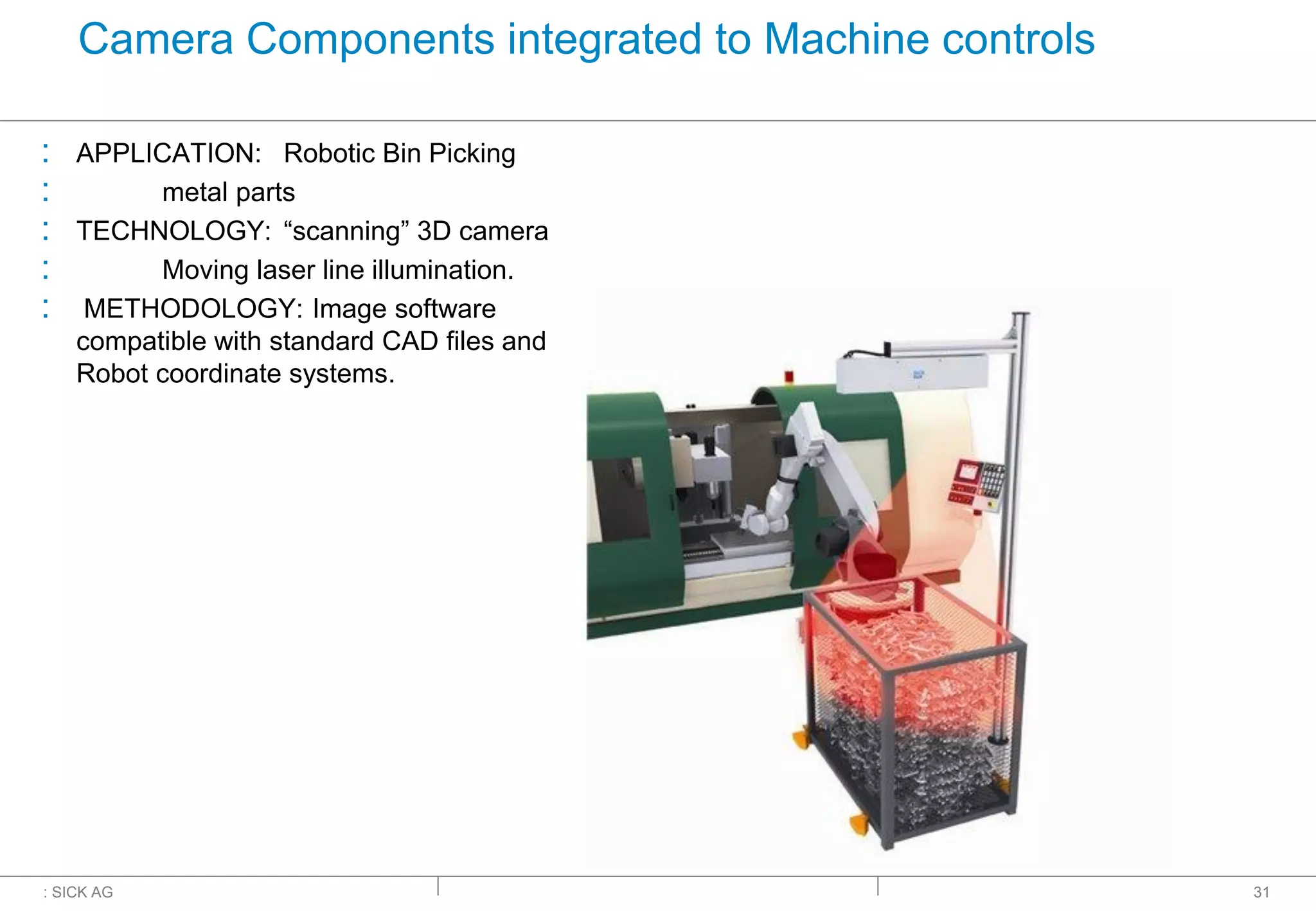

This document provides an overview of machine vision and examples of its applications. It discusses what machine vision is, when it is used, and common camera types. Machine vision is defined as using cameras to analyze images and extract data to control automated processes. It is used to improve quality, simplify workflows, and reduce waste and costs. Examples are provided of simple vision sensors, smart cameras, and PC-based camera components used for applications like object counting, positioning, and inspection. The benefits of machine vision for quality control and profits are highlighted.