This document summarizes several articles from the July 2009 issue of CHE magazine. It discusses recent advances in mixing technology that offer increased efficiency in dispersing powders in low- and high-viscosity applications. It also briefly outlines other articles about separation processes offering more efficiency and purity, attendees not being disappointed by Achema 2009 despite economic turmoil, and facts about flowmeter selection.

![Letters

Passionate GHG arguments

I must applaud you on your May Editor’s Page com-

ments in “Keep the GHG debate on point”.

I believe there are three distinct aspects to the issue that

should not be commingled. First is “global warming”, which

is a natural phenomena that has occurred about every 1,500

years for the last million or so years that we can track it.

It’s happening, and there is nothing we can do about it.

The second is the role that CO2 plays in this, which is little

to nothing, certainly nothing that puts responsibility on

human factors. The third aspect is improving energy effi-

ciency, and reducing dependency on fossil fuels.

Certainly it is necessary to reduce greenhouse gases

that clearly have an impact on the world, basically pol-

lution and health. But CO2 isn’t one of them. I have seen

people use the numbers you quote in the reverse, by mak-

ing them into “CO2 equivalents”, to emphasize a reduction

in CO2, not the GHG itself.

To move to a so-called cap-and-trade approach to reduc-

ing CO2 emissions, which could mean severe limitations

(taxes) on coal energy production or exhaust emissions, is

a big mistake. Making efforts to increase fuel efficiency

to either make our fossil fuels last longer or reduce de-

pendence on foreign oil, is probably a good thing, and if

that can be done by mandating better fuel efficiency for

vehicles, well maybe that’s a better idea.

Tom Rolfes

Rolfes International LLC, Wyoming, Ohio

I just finished reading your editor’s page comment on

anthropogenic global warming. I would recommend

the following areas of study for you or your magazine

in order for you to have a more rounded opinion on an-

thropogenic global warming.

Circle 07 on p. 54 or go to adlinks.che.com/23016-07

• Ice core data and CO2

• eaf stomata and CO2 atmospheric levels

L

• CO2 atmospheric sampling pre and post 1957

• 13C isotopic concentration of the atmosphere

• cean currents and their effects on weather patterns

O

• O2 concentrations of seawater and their variations

C

due to locale

This is just a small list of topics that when researched

would give any scientist doubt as to the validity of

CO2 induced global warming. I will not go on and

make any negative remarks about your insulting

comment that any belief against anthropogenic [CO2]

induced global warming is nonsensical and likening

those who fight this belief as being akin to possessing

elementary-school-like minds as it pertains to science.

John Benkovic

Plant manager, CIL Isotope Separations

The editorial does not make any arguments for or against the

premise of anthropogenic global warming. It merely argues

that life-giving characteristics ALONE do not form the basis

for a pollution exemption. Nor does it suggest that those who

fight this belief possess elementary-school-like minds. Instead,

it calls for deeper scientific education on the issue than that

related to CO2’s life giving characteristics. — Ed.](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-8-320.jpg)

![Edited by Gerald Ondrey July 2009

NH3

A gypsum-free, energy- Water

saving route to lactic acid Sugar

Fermentation

Precoat- Ultra- SMB-

Evaporation

filtration filtration chrom.

U hde GmbH (Dortmund, Germany; www. Nitrogen

uhde.biz) is developing a new process for

H2SO4

producing lactic acid (LA) — a monomer for

Lactic acid

making the biodegradable plastic polylactic with ammonia, which is added to adjust the Amm.sulfate

evaporation

acid (PLA) — that does not require a distil- pH. After the fermentation — which produces

lation step. As a result, savings in steam and more than 130 g/L LA titer (productivity 4

electrical power are calculated to be up to g/Lh) — the broth is filtered and sulfuric acid Amm.sulfate

€100/ton of LA, says Joachim Schulze, head is added to release the LA. Finally, simulated- crystallization/

granulation

of Uhde’s biotechnology division. moving-bed (SMB) chromatography and

In conventional routes, lactic acid is made evaporation are used to recover LA with pu-

(NH4)2SO4

by the fermentation of sugar using bacteria, rity sufficient for making PLA. The LA yield

such as lactobacillus, streptococcus or pedio- is better than 90%, says Schulze. Instead of

coccus. As LA is produced, lime milk [satu- producing low-value gypsum, the new route

rated aqueous Ca(OH)2] is added to keep the generates ammonium sulfate, which can be FutureGen

pH from becoming too acidic for the bacteria made into fertilizer granulate. The U.S. Dept. of Energy (DOE;

to survive. After fermentation, sulfuric acid is Uhde has been developing the new pro- Washington D.C.; www.doe.

added to convert the calcium lactate into free cess at a test facility in Leipzig since 2007, gov) has revived a program

acid, producing gypsum (CaSO4) as a byprod- and recently performed a toll operation (50 for a commercial-scale dem-

onstration of a fully integrated

uct. The crude LA is separated by filtration m3 fermenter) in the Czech Republic. Plans

plant that would combine coal

and clarification of the broth and evaporation are underway to build a pilot plant, and gasification, H2 production,

of the water, and then purified by distillation. ultimately integrate the LA process into electricity generation, and

The new process (flowsheet) uses a thermo- the PLA process of Uhde Inventa-Fischer CO2 capture and underground

phyllic bacteria strain that is also compatible GmbH (Berlin). storage. The program, called

FutureGen, had been dropped

by the Bush Administration in

New catalyst boosts liquid-fuel yield 2008 because of the cost.

DOE has signed an agree-

from heavy hydrocarbons ment with the FutureGen

Alliance (Washington, D.C.;

A new zeolite catalyst that increases yields

of light cycle oil (LCO) from high molecu-

lar weight “bottoms” hydrocarbons in petro-

with more acidic-active sites and pore struc-

tures that blunt the poisoning effects of con-

taminant metals (Fe, Ca, Ni, V), improves the

www.futuregenalliance.org),

an industrial sponsorship

group, with the goal of build-

leum fluid catalytic cracking (FCC) units selectivity of the catalyst in gasoline- and ing a plant in Mattoon, Ill. The

was commercialized last month by Grace- LCO-forming reactions compared to conven- agreement calls for $1.073 bil-

Davison, an operating segment of W.R. tional FCC catalysts, says Schiller. Midas lion to be contributed by DOE

Grace Co. (Columbia, Md.; www.grace. 300 “selectively cracks naptheneoaromatic and $400–600 million by the

com). Observed gains in LCO (boiling point compounds without a coke or gas penalty.” Alliance, a group of interna-

430–650°F) yields of up to 6% are significant Midas 300 optimizes catalysis of three tional companies that includes

to petroleum refiners seeking to improve bottoms-cracking mechanisms, including electric utilities and coal com-

panies. A final decision either

production of valuable liquid products, such pre-cracking of large molecules on the cata-

to move forward or discontinue

as transportation fuels and chemical feed- lyst matrix, zeolite-catalyzed dealkylation of the project will be made in

stocks, from heavy hydrocarbons (HCs), says aromatics and long-chain breakage, as well early 2010, following a detailed

product manager Rosann Schiller. as the destruction of napthene rings. cost study.

Known as Midas 300, the USY- (ultra- Midas 300 catalyst has been in commer-

stable Y-type) zeolite-containing catalyst de-

rives its enhanced activity from an increase

cial use at two FCC units in North America

and an additional plant in the Asia-Pacific

Li-ion cathode

Last month, BASF Corp.

in mesoporosity of the catalyst matrix. Mes- region since late 2008. The facilities include

(Florham, N.J.; www.basf.

oporosity refers to pore sizes in the range a small gas-oil refinery and a large, residual com) signed a global license

of 100 to 600 Å — critical for allowing free fuel-oil processor. Schiller notes that the eco- agreement with DOE’s Ar-

diffusion of heavy HCs into the catalyst. nomic value of a 6% yield increase in liquid gonne National Laboratory

Greater mesoporosity improves overall se- products varies depending on the size of the (ANL; Argonne, Ill.; www.anl.

lectivity by converting coke precursors into FCC unit, the type of feed and the operat- gov) to mass-produce and

liquid product, explains Schiller. ing conditions, but benefits in the range of

(Continues on p. 14)

Enhanced catalyst mesoporosity, coupled $0.75–1.50/bbl have been reported.

Note: For more information, circle the 3-digit number

on p. 54, or use the website designation. Chemical Engineering www.che.com July 2009 13](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-15-320.jpg)

![C hementato R (Continued from p. 13)

market ANL’s patented com-

posite cathode materials for

advanced lithium-ion batteries.

Direct conversion of cellulose to HMF demonstrated BASF will further develop the

technology at its Beachwood,

R esearchers at Pacific Northwest National

Laboratory (PNNL; Richland, Wash.;

www.pln.gov) have published the first di-

CrCl2) dissolved in an ionic liquid (1-ethyl-

3-methylimidazolium chloride) at tempera-

tures of 80 to 120°C to catalyze the single-

Ohio facility.

ANL’s cathode is a combina-

tion of lithium- and maganese-

rect route for converting plant cellulose to step conversion of cellulose to HMF. In the rich, mixed-metal oxides

5-hydroxymethylfurfural (HMF), a valuable laboratory, the process achieves an unrefined designed to extend operat-

platform chemical for the production of both purity of 96% among recoverable products, ing time between charges,

plastics and biofuels. Appearing in the June and an overall HMF yield of about 55%. increase the lifetime and

issue of Appl. Cat. A, the research could Principal investigator Conrad Zhang, who improve the inherent safety of

mark a pathway to less expensive, large- has since left PNNL, says that cellulose de- Li-ion cells. Enhanced stabil-

scale production of HMF. polymerization occurs at a rate one order of ity of the composite material

Although a two-step process of HMF magnitude faster than conventional acid- permits batteries to charge to

higher voltages, which leads to

formation from plant biomass via simple catalyzed hydrolysis. The research group

a “substantially” higher energy-

sugars has been demonstrated previously, evaluated a wide range of metal chlorides storage capacity, says ANL.

a mild-temperature, single-step process to and found that a combination of CuCl2 and BASF plans to commercial-

convert cellulose directly to HMF has re- CrCl2 at a catalyst load of 37 μg/mol gener- ize these cathode materials for

mained elusive. ated the highest HMF yields. Experiments transportation and other appli-

PNNL’s conversion process relies on the are underway to elucidate the reaction cations. Contingent upon win-

use of twin metal chlorides (CuCl2 and mechanism, which is not yet understood. ning a DOE grant under the

Recovery Act (Electric Drive

A new support for biofilters Vehicle Battery and Compo-

nent Manufacturing Initiative),

the company plans to build a

R esearchers from the Environmental Bio-

technology Cooperative Research Center

(Sydney and Perth, Australia; www.ebcrc.

face of the zeolite and the internally porous

crystalline structure of regularly spaced

cavities provide large surface area and mo-

cathode-material production

plant in Elyria, Ohio.

com.au) have developed a new way to har- lecular sieve properties. According to the

ness bacteria to biodegrade odor-causing researchers, those properties make zeolite

CO2 capture

substances. Traditional biofilters typically a filter bed material capable of adsorbing Last month, Alstom (Paris,;

www.alstom.com) signed an

employ compost supported on wood chips odors, as well as provide surfaces for micro-

engineering, procurement

to trap the odor-producing substances, and organisms to form a biofilm to biodegrade and construction (EPC) con-

rely on micro-organisms in the compost to the adsorbed odors. Since zeolite is inert, tract with StatoilHydro ASA

break down those substances. The center’s there is no need to replace it. Backflush or (Stavanger, Norway; www.sta-

executive director, David Garman, says that backwash should be enough to reduce block- toilhydro.com) on behalf of the

“while bacteria can deal with a wide range age caused by biofilms. partners of the European CO2

of odors, their unreliability, poor viability A fully automated laboratory-scale (1-L) Technology Center Mongstad

and poor performance in normal biofilter plant, with two separate filter reactors, has (TCM; Norway) for a chilled-

systems mean that often operators prefer to been constructed. Using ammonia as a model ammonia, CO2-capture plant.

use simpler chemical systems. Some of these compound to understand the mechanism The demonstration plant will be

the first one of its kind to treat

systems are effective at masking the odors of odor removal, experiments have demon-

fluegas (FG) from a gas-fired

but do not remove or break them down.” strated that the adsorption capacity of the power plant, says Alstom.

The center’s new technology replaces the zeolite bed is comparable to that of conven- Alstom will supply and install

compost and wood chips by a non-biodegrad- tional biofilters. The next step will be to dem- the demonstration plant —

able matrix that also acts as an adsorbent. onstrate the system using odor-degrading scheduled to start up in No-

A naturally occurring zeolite is used for micro-organisms. A full pilot plant will be set vember 2011, which will use the

that purpose. The electrically charged sur- up shortly in Perth, Western Australia. company's chilled ammonia,

post-combustion technology

(for process details, see CE,

Using gold to catalyze oxidation reactions April 2008, p. 13) to capture

CO2 from FG of a combined

P olymer-supported nanoclusters of gold

have recently been shown to catalyze

the oxidation of alcohols to ketones at room

dation reactions continuously. The catalyst

strongly binds to the 0.25-µm-thick polysi-

loxane coating of a commercially available

heat and power plant at Mong-

stad. It will also treat FG from a

petroleum processing plant at

temperature in air by the research group of gas-chromatography capillary tube [Inert- the nearby Mongstad refinery,

chemistry professor Shu Kobayashi, Uni- Cap 225 from GL Science Co. (Tokyo)]. As a which has a CO2 output equal

versity of Tokyo (www.chem.s.u-tokyo.ac.jp), test of the system, 1-phenyl ethanol was oxi- to that of a coal-fired power

in a project supported by Japan Science dized to the corresponding ketone with high plant. The TCM facility will cap-

and Technology Agency (JST). Now, the re- yield. After four days of continuous opera- ture up to 100,000 metric tons

searchers have developed a procedure to de- tion, no loss of catalyst or catalyst activity (m.t.) per year, of which chilled

posit the gold catalyst onto the inside walls was observed. Improved yields and selectiv- NH3 will capture 80,000 m.t./yr

— the equivalent of a 40-MWth

of glass capillary tubes, which can then be ity have also been observed by oxidation in a

power plant.

used as tubular reactors for performing oxi- palladium-gold-supported capillary system.

14 Chemical Engineering www.che.com July 2009](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-16-320.jpg)

![The missing piece for A new way to make BDO from sugars

wireless process control Genomatica (San Diego, Calif.; www.genomatica.com) has developed a process for

the production of commercial-grade 1,4-butanediol (BDO) from renewable feedstocks,

announcing last month that it can produce BDO at greater than 99% purity. In addition

L ast month, Honeywell Process So-

lutions (HPS; Phoenix, Ariz.; www.

honeywell.com/ps) unveiled the process

to glucose and sucrose, the ability to use xylose has also been demonstrated, which

may lead to the development of second-generation processes that consume the carbo-

hydrates of lignocellulosic biomass.

industry’s first redundant wireless sys- In the cost-efficient, scalable process, BDO is produced directly in a fermentation broth

tem gateway (WSG), connecting the last from sugars by strains of bacteria that are tolerant of the commercial target concentra-

major gap in the path to wireless process tions. The yield and rate of BDO production needed on a commercial scale are achieved.

control. WSGs manage data between Operations at a demonstration plant will be underway by 2010 with an expected ca-

pacity of approximately 1 ton/d. When the demonstration plant validation is complete,

wireless field instrumentation and a

Genomatica plans to commercialize the process through partnerships. ❏

plant’s process control network. Redun-

dancy between the wireless instruments

themselves and their assigned gateway do that wirelessly?” says Becker. advantage, he points to one of the first

was already a reality since the introduc- The redundant WSG overcomes impor- commercial installations planned for

tion of so-called wireless mesh networks. tant programming hurdles, such as the the new system, a 35-tank, monitoring

Prior to this latest release, however, any- avoidance of signal confusion from dual and control system in Houston where

one using wireless networking still had a gateways without more than a 2-s delay. the quote to install a wired system was

reliability risk: that if a gateway failed, so Meanwhile, unique failure-recovery fea- 50% higher than for the wireless setup.

would the signals being routed through tures help prevent data loss, Becker says. Depending on location, the savings

it, explains Jeff Becker, global wireless The release is especially timely for could be closer to 70%, he says. And,

business director at HPS. “We would not the vast number of aging facilities with that completes the upfront capital for

expect our customers to run [process] control networks and instrumentation a full wireless network in which subse-

control over wires without full redun- that are nearing the end of their life- quent wireless devices can be added for

dancy, so why should we expect them to cycle, Becker says. To illustrate the cost “hardly anything”. ■

www.hoerbiger.com

Circle 18 on p. 54 or go to

adlinks.che.com/23016-18

For more information please contact

compressor-mechatronics@hoerbiger.com](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-21-320.jpg)

![CDS

Newsfront

Loewenberg, GEA provides mechani- in this way will most always pro-

cal vapor recompression, where in- vide payback without higher cap-

stead of using steam, boiled-off vapor ital costs.

is compressed and used again as a Process efficiency is also on

heating source. many processors’ wish lists, espe-

Membrane technology, too, is an- cially when it comes to substance

other application for reducing energy separation. “We see a lot of inter-

use in separations, according to Kevin est from operators in subsea oil Figure 2. The CDS StatoilHydro Inline de-

Donahue, business manager for indus- processing in doing their separa- liquidizer has been applied at a number of

fields, de-bottlenecking or replacing large,

trial processes with Koch Membrane tions in a more compact and ef- conventional gas scrubbers with ultra-com-

Systems (KMS; Wilmington, Mass.). ficient way,” says Rune Fantost, pact separation in pipe segments

For example, if a plant is processing technology director of CDS Sepa-

at full capacity but wants to boost pro- ration Technology (Houston), which we can offer them solutions upstream

duction further, debottlenecking the is part of FMC Technologies’ Separa- or downstream from the existing ves-

evaporator could help. “In these cases, tion’s Group. “In this field they have sels that can increase capacity and

the companies should consider the use been seeking a technology that will performance,” says Fantost.

of a membrane to remove water from permit inland separation using pipe CDS has worked with a variety of

the fluid ahead of the evaporator to segments instead of large vessels.” operators to develop compact, inline

preconcentrate the liquids or solids,” The quest for this technology is separation technology. “We’ve spent a

explains Donahue. “The membrane driven by bottlenecks and operating lot of time qualifying this technology

could provide a factor of five or ten problems offshore on the platforms, to come up with operating envelopes

times more energy efficiency com- which creates the need to find a simple and how it will perform in different

pared to an evaporator [alone].” way to retrofit. “They have a certain applications with the major oil com-

While he says the exact savings number of separation vessels and they panies,” says Fantost. The result is a

are plant specific, using membranes don’t want to replace those vessels, so line of inline separators based on com-

“QUALITY PRODUCTS

DESIGNED AND TESTED TO

SATISFY CUSTOMER NEEDS.”

At Valve Concepts, Inc., we realize that quality can’t be

inspected into a product. Instead, it starts in the factory,

where we employ an ISO 9001:2000 Quality Assurance

Program to ensure compliance to international

standards.

Our commitment to engineering excellence also

extends to our own state-of-the art, full-scale test facility,

where we collect and analyze flow performance data.

We’re comparing the results against our own standards

— which are often higher than those stated in API

requirements. It’s just one more way that “We simply make

it right.”

Darrin Vanderbilt, Engineering Lab Manager

7 Years Industry Experience

www.cashco com

Cashco, Inc., P.O. Box 6, Ellsworth, KS 67439-0006, Ph. (785) 472-4461, Fax: (785) 472-3539 Innovative Solutions

Circle 20 on p. 54 or go to adlinks.che.com/23016-20

22 ChemiCal engineering www.Che.Com July 2009

CAS-179A.indd 1 11/25/08 2:49:35 PM](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-24-320.jpg)

![Newsfront

John D. Allen, president of Pump So- www.chemstations.com)

lution Group (Redlands, Calif.; www. • This Achema feels like a

“

pumpsg.com), who has been coming success, and we are very

to Achema for 27 years. “In Hall 9 happy with the resonance,” Achema visitors get a hands-on look at equipment

you can see the entire global pump says Helmut Gänser, Ge-

industry in one place. In this down schäftsführer, Ekato Holding GmbH about the outcome, but for the first

economy, it’s the only show where I (Schopfheim, Germany; www.ekato. three days we had more leads than

can imagine so many vendors com- com). “It has been much better than Achema 2006.” — Markus Steinke,

ing together. Achema is also a driv- we expected — even better than 2006. international marketing manager,

ing force in distribution, and our Achema is very important to Ekato. Metrohm AG (Filderstadt, Germany)

customer numbers are up at 2006 We have been at every Achema since • We are more than pleased with the

“

levels, too.” the 1920s, and this year our stand is way Achema has progressed this

• We are extremely happy with the

“ twice as big as last time.” year. There was no sign of katzen-

number of attendees at the show, and • I was very curious about the turn-

“ jammer [distress] here; in fact, just

the number of visitors to our booth. out, given the downturn, but have the opposite. We could discuss very

Exhibition at Achema has allowed us been pleasantly surprised. We are concrete project enquiries, some-

to visit with several of our current very pleased at the number and thing that was not anticipated in

customers, create many new contacts high quality of visitors.” — Rich Al- light of the current economic cli-

for future business, and continue to tice, vice president, commercial ser- mate. Also, the quality of the techni-

understand the challenges facing the vices, Solutia, Inc., St. Louis, Mo.; cal visitors has again increased.” —

chemical industry. We have six [em- www.solutia.com) Michael Ziesemer, COO and member

ployees] in our booth, and we have • Achema 2009 is the best opportu-

“ of board, Endress+Hauser (Reinach,

been busy throughout the show meet- nity for us to meet customers from Switzerland; www.endress.com)

ing visitors.” — Steve Brown, COO, all over the world. In this economic • For over 25 years, Achema has been

“

CPD-5 8/20/07 Inc. (Houston, Tex.;

Chemstations, 10:34 AM Page 1 climate, we were a little bit worried a traditional event for us to meet

customers and business partners.

This year the expectations were ad-

mittedly somewhat dampened. But

The best way to heat and cool the interest in our technology is

high, the number of visitors is good

the most corrosive materials.

and there doesn’t seem to be any

slump at the moment.” — Harald

Nothstain, Geschäftsführer (Lurgi

GmbH, Frankfurt; www.lurgi.com).

Looking ahead to 2010

Following the successful Achema

2009, preparations are already under-

Nothing controls way for the 8th AchemAsia, which will

temperatures of take place at the new China National

corrosives and high Convention Center (CNCC) in Beijing

purity materials better (June 1–4, 2010). With its convenient

and central location in the immedi-

than AMETEK fluoropoly-

ate vicinity of Beijing’s Olympic park

mer heat exchangers. Not — the building was the press hub for

glass. Not silicon carbide the Olympics, so its well equipped

or graphite units. Available with the latest IT technology — and

with steel or non-metallic its modern hall layout, CNCC will

shells, diameters from 3 offer AchemAsia the long-awaited op-

to 14 and metric designs, portunity for development, said Kurt

AMETEK heat exchangers Wagemann, deputy chief executive of

include TEMA/ANSI nozzle and Dechema. (Wagemann will assume

end connections. To learn more the chief executive position following

call (302) 456-4431 or visit: the retirement of Professor Kreysa at

the end of this year). “The new facili-

www.ametekfpp.com

ties will, for the first time, enable the

desired integration of the congress

and the exhibition,” he says. n

Gerald Ondrey

Circle 23 on p. 54 or go to adlinks.che.com/23016-23

26 Chemical Engineering www.che.com July 2009](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-28-320.jpg)

![Engineering Practice

Feature Report

The Shotgun Approach

Removal of Fouling Deposits on heat transfer

surfaces in Coal-Fired Process Heaters Boilers

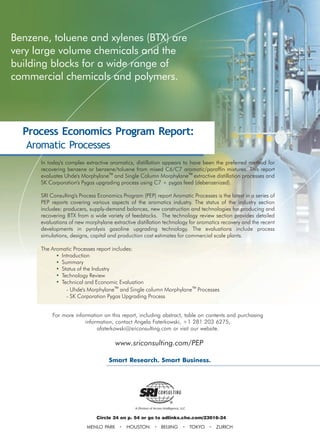

When conventional soot FIGURE 1. Shot Blasting Data

ln PBR versus ln Px

blowers are inadequate, 10.8

an automated shot- 10.6

blasting system offers a 10.4

Table 3

powerful solution 10.2

data

10.0

Point at

Alan Cross 9.8 8,500 psi

T

Table 1 and 2

he heat transfer surfaces of coal- 9.6 data

ln PBR

fired process heaters and boilers

often undergo severe fouling. If left 9.4

intact, such deposits, consisting of 9.2

slag from mineral matter contained

in the coal, can reduce heat-transfer- 9.0

surface availability, reduce thermal ef- Point at

8.8

ficiency and cause corrosion. 3,600 psi

If the deposits are adherent and 8.6

cannot be removed by conventional

steam soot-blowers, shutdown and 8.4

more rigorous cleaning is required.

8.2

Maintenance personnel have been

known to use shot cleaning as a means 8.0

of removing stubborn deposits. 8.0 8.2 8.4 8.6 8.8 9.0 9.2 9.4 9.6 9.8 10.0 10.2 10.4 10.6 10.8

Operating costs for heaters and boil- ln Px

ers of the type described above, can be

reduced, due to increased on-stream Figure 1. The linear relationship of ln Px versus ln PBR is of great practical

time, through installation of perma- importance in calculating unknown performance characteristics

nent, on-stream shot-blasting equip-

ment for adherent deposit removal. trical generating capacity of 125 MW, shot blasting may not be necessary at

This equipment consists of strategi- could avoid a loss of electricity sales this location.

cally placed semi-automatic shotguns sufficient to pay for the cost of the shot However, shot blast cleaning is ap-

(see box on p. 47), utilizing steel shot blasting equipment described herein, plicable for process heaters only with

backed by a solid propellant in the in about one year if shot blasting were tubular heating surfaces devoid of ex-

form of shotgun ammunition. The am- provided for the radiant section only, posed refractory, which could be dam-

munition contains the normal quota of or in about two years, if shot blasting aged by the shot [4]. Likewise, to be

shot, backed by a tailored amount of were provided for both the radiant applicable for this technique coal-fired

propellant such that the shot impact and convection sections. It should be boilers must be, and usually are, pro-

force on tube fouling deposits would be noted, however, that because the flu- vided with tubular heating surfaces

several or many times that created by egas temperatures prevailing in the without open spaces between tubes.

conventional soot-blowers. convection section may be below the Such surfaces are often referred to as

Calculations based on realistic cost ash-fusion temperature, it is possible membrane surfaces.

data [7], indicate that if an outage of that lighter tube-slag deposits may

15 days per year could be avoided, be seen in the upper convection sec- Design calculations

through use of the proposed shot-blast- tion than in the lower radiant section If the impingement areas of the steam

ing equipment, a boiler having an elec- of the boiler. Thus, convection section jets or shot diameters are known, the

44 ChemiCal engineering www.Che.Com July 2009](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-62-320.jpg)

![Table 1. Summary of available and CalCulated data for a Table 3. lead and Steel

30-06 rifle with 26-in. barrel, Savage model 116 Shot muzzle veloCity at full

and reduCed ProPellant

Case 1 1a 2*

loadingS

Lx, Calculated 24.5 25.5 21.6. Lead Steel

Vm, Specified 2,400 2,400 2,700 Shot Shot

Ro, Calculated 2,000 1,920 2,480 Lb, in. 20 20

Lx, in. 6.9 7

Px, Calculated /Specified 28,285/N.S. 27,200/N.S. 35,100/37,400

Wb, grains 547 373

Pm, Calculated 26,665 27,000 27,000

Wp, grains [6] 25 11.0

Vx, Calculated 2,274 2,261 2,492

Px, psi 8,500* 3,668

PBR, Calculated 27,900 26,700 35,300

Pm, psi 2,920 1,284

Wp, Specified 50.1 51.0 51.0

Vx, ft/s 918 735

Wb, Specified 180 180 150

Vm, ft/s 1,383 1,102

* See Ref. [8]; N.S. = not specified * 8,500 psi is the approximate maximum bar-

Cases (1A) and (2) in accordance with Equations (5),(6),(8) and (10) rel pressure measured by the so-called “lead

Case (1) in accordance with base straight line ln–ln plot of Figure 1 cup method” wherein the degree of deforma-

tion of a lead cup, exposed to barrel pressure,

is used as a measure of the peak pressure (see

Table 2. Summary of available and CalCulated data Ref. [5].

for 0.44 magnum handgun with 4-in. barrel

Smith and weSSon model m29 sure and velocity at the muzzle, and

Case 1 1a 2 2a 3 3a properties of the propellant, such as

propellant burn rate. These variables

Lx, Calculated 3.0 2.0 3.0 2.0 2.5 2.0

are determinable from the equations

Vm, Specified 926 926 853 853 1,203 1,203 derived in the box on p. 46.

Ro, Calculated 1,628 2,443 1,791 2,690 3714 4,642 Propellant burn rate (PBR), as de-

termined from these equations, also

Px, Calculated 10,718 16,076 11,789 17,700 24,440 30,546

shows the relationship between burn

Pm, Calculated 8,038 8,038 8,842 8,842 15,273 15,273 rate and propellant weight (Wp), ve-

Vx , Calculated 718 714 652 648 857 852 locity at the point of propellant burn-

out (Vx) and barrel length at the point

PBR, Calculated 7,180 10,200 7,172 10,692 19,540 28,200 of burnout (Lx), as determined from an

Wp, Specified 5.0 5.0 5.5 5.5 9.5 9.5 analysis of firearm performance for a

Wb, Specified 180 180 240 240 240 240

number of different firearms having

known values of propellant weight,

Cases (1A), (2A) and (3A) in accordance with Equations (5), (6), (8) and (10). bullet weight (Wb), muzzle velocity

Cases (1), (2) and (3) in accordance with base straight line ln–ln plot of Figure (1).

(Vm) and barrel dimensions (see Tables

1 and 2). These data have shown that a

force on the tube-surface fouling ma- with a reduced loading of propel- straight line relationship exists when

terials can be predicted and the fol- lant. An approximate value of K the natural logarithm of pressure at

lowing equation is applicable: is 4, based on 1/16-in.-dia. steel propellant burnout (Px) is plotted as

shot at 1,100 ft/s, a 1/16-in. slag a function of the natural logarithm

( )(

Wshot ⋅ Vi − Vf ⋅ Vi + Vf ) = K ⋅W ⋅V

s s

2

⋅ As layer, and a 2-in.-dia. steam jet at of the burn rate (Figure 1). The same

2 ⋅ g ⋅ Ls g 1,200 ft/s relationship has been demonstrated

Ws = Steam density, lb/ft3 by other investigators [3]. This would

(1) Vs = Sonic velocity of steam, ft/s indicate that the propellants used for

Where: Ls = Thickness of slag layer, ft all of the cases investigated had com-

Wshot = Individual steel shot weight, lb As = Cross-sectional area of steam parable burn rates.

Vi = Velocity of shot at slag layer, ft/s jet, ft2 The linear relationship of ln Px ver-

Vf = Velocity of shot at tube wall, ft/s, g = Acceleration of gravity, ft/s2 sus ln PBR has been shown to be of

and should be zero Note that the data required to com- great practical importance in calcu-

K = A multiplication factor, experi- pletely define shot blasting perfor- lating unknown performance charac-

mentally determined or calcu- mance and mechanical design include teristics, when the only available data

lated, so as not to cause tube such variables as: muzzle velocity, for calculation purposes, to determine

damage, would be based on a full recoil force, peak barrel pressure, values of Pm, Px, Vm, Vx, Lx and PBR,

loading of shot in combination velocity at propellant burnout, pres- consists of Wp,Wb, Db, Lb, and Px for at

ChemiCal engineering www.Che.Com July 2009 45](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-63-320.jpg)

![Performance calculations

The pressure in the shot blasting barrel can be calculated from Wb dV Wb dV

Equation (3), which was derived assuming ideal gas behavior, Pb ⋅ Ab = ⋅ = ⋅V ⋅

and from data obtained from Ref. [3]. g dT g dL (7)

Where

V W Pb = Average barrel pressure, psi

Pbarrel = 2 ⋅ 1 ⋅ Pmax

V W

1 2 Wb = Total shot weight, lb

(3) g = Acceleration of gravity = 32.2 ft/s2

Where V = Bullet or shot velocity, ft/s

V2 = he volume (in.3) of a fully enclosed experimental ves-

T T = Time, s

sel in which a sample of a propellant is burned, in this Ab = Inside cross-sectional area of barrel, in.2

case a sample of nitrocellulose The following equations are the result of integrating Equation (7)

V1 = he volume (in.3) of the cavity formed from the barrel

T between appropriate limits as follows: In the zone of ascending

breech to a point in the barrel where internal pressure pressure, V varies from 0 to Vx as L varies from 0 to Lx; In the

is at a maximum due to complete burning of the pro- zone of decreasing pressure, V varies from Vx to Vm as L varies

pellant used from Lx to Lb.

W1 = The weight of propellant used, grains

W2 = he weight of propellant charged and burned in the

T (P x

+ 0)

=

0.0000339 ⋅ Wb ⋅ Vx2

enclosed experimental vessel, grains

Pbarrel = Pressure in barrel corresponding to W1 and V1, psi

2 Lx ⋅ Db

2

(8)

Pmax = he maximum pressure developed in the experimental

T Where

apparatus based on complete burning of the sample Wb = Total shot weight, grains

charged, psi Vx = elocity at point of maximum barrel pressure at propel-

V

The maximum pressure so developed is 57,000 psi and should lant burnout, ft/s

be practically the same for any nitrocellulose-based propellant Px = Maximum barrel pressure, psi

because the gas generated and temperature developed is primar- Lx = Length of bullet or shot travel corresponding to Vx, in.

ily a function of the chemical composition of the propellant and Db = Barrel inside dia., in.

does not vary much, unless the overall propellant composition is

considerably different from that of nitro-cellulose. (P x

+ Pm )

=

0.0000339 ⋅ Wb ⋅ Vm − Vx2

2

( )

The following equations are the result of substituting appropriate

variables in Equation (3):

2 Db ⋅ ( Lb − Lx )

2

(9)

Where

1, 245 ⋅ Wp Pm = Pressure at muzzle, psi

Px =

Db ⋅ Lx

2

Vm = Muzzle velocity, ft/s

(4) Lb = Barrel length, in.

Where: Dividing (8) by (9) gives,

Px = aximum barrel pressure at the point of complete pro-

M

pellant burnout, psi Px

=

Vx2

⋅

(L

b

− Lx )

Wp = Weight of propellant used, grains

Db = Inside diameter of the barrel, in. (P x

+ Pm ) (V2

m

−V x

2

) Lx

(10)

Lx = ength of barrel from the breech to the point of maxi-

L The propellant burn rate (PBR, grains/s) can be calculated from

mum pressure, in. Equation (11)

1, 245 ⋅ Wp 6 ⋅ Wp ⋅ Vx

Pm = PBR =

D ⋅ Lb

2

Lx

b

(5) (11)

Where: As noted previously, PBR is a function of Px. The equations cor-

Lb = Total barrel length, in. relating these variables are:

Pm = Pressure at the muzzle, psi PBR = 1.082 ⋅ ( Px − 8,103) + 4, 447

Dividing Equation (4) by Equation (5) results in the following: (12)

R = 0.785 ⋅ P ⋅ D 2

Px Lb O x

b

(13)

= Where

Pm Lx

(6) Ro = ecoil force (lb) based on maximum barrel pressure,

R

Equation (7) is based on the well known relationship between without considering effects of shot-barrel friction. The

force and acceleration: recoil force would be needed for the mechanical design

of the shot-blasting device. ❑

least one set of data. (See box, “Perfor- pared favorably with the specified val- Sd = Barrel design stress, psi

mance Calculations,” Equations (5), (6), ues, as did the calculated barrel wall The propellant burn rates for rifles

(8) (10) and (11), Table 3 and Ref. [5]). thickness, as given by Equation (2). and hand guns are similar to those

Unfortunately, the barrel length, Pmax ⋅ Dbo for shotguns (Tables 1 and 2), but the

Lb, of Table 3 was not specified, so t= calculated data for these tables are

an average barrel length of 20 in. has (2 ⋅ Sd + Pmax ) (2) based on Wp, Wb, Lb, Db and Vm, in

been assumed. Where: as much as peak barrel pressure data

The calculated data of Table 3, t = Barrel thickness, in. were unavailable.

namely, the muzzle velocity, Vm, and Pmax = Maximum pressure, psi As regards the data of Tables 1 and

maximum barrel pressure, Px, com- Dbo = Barrel outside dia., in. 2, there is some uncertainty, as to the

46 Chemical Engineering www.che.com July 2009

16_CHE_070109_GSO.indd 46 6/29/09 10:51:44 AM](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-64-320.jpg)

![Engineering Practice

Table 4. Coverage of Heating Surface Elements tem, however, is the need for position-

by Steel and Lead Shot ing the blasting gun at an angle, both

Shot Material Steel Lead horizontally and vertically, at which a

Shot diameter, in. 1/16 1/16 gun must be fired in order to achieve

full coverage of the available heating

Distance, muzzle to target, ft. 50 20

surfaces. This is to be accomplished

Shot muzzle velocity, ft/s 1,200 1,200 automatically, at each blasting sta-

Shot velocity at target, ft/s 1,170 1,165 tion, by means of two linear-step

Shot spacing at target impact, in. 0.56 0.28

movement motors, one for horizontal

movement in the x direction and one

Shot pattern diameter, ft. 2.0 1.0 for vertical movement in the y direc-

Shot surroundings Flue-gas Air tion. For the case in point, wherein

Temperature of surroundings, °F 2,000 60 each firing covers an area of about 2

ft in dia., there would be a 4 4 fir-

the performance of the shot-blasting lutely necessary. The preferred calcu- ing grid comprising a total of 16 firing

equipment; Vm, Vx,, Px, Pm, Lx, Db, Lb, lation method is one wherein at least positions having 16 (x, y) coordinates

Wp, Wb, PBR, and Ro. The unknown two base data points, based on the and covering a total area of 64 ft2. If

variables and known variables must same propellant, are made available, operating experience were to indicate

therefore equal 11. Furthermore, so as to ensure that a proper slope is that all of the firing positions avail-

there are a total of seven independent obtained for the log-log plot, thereby able were not necessarily needed, an

Equations (4), (6), (8), (10), (11), (13), lending confidence to the calculation appropriate set of coordinates could

and the straight line defined by the and extrapolation of data points lying be chosen as input to the sequencing

plot of ln PBR versus ln Px. The total inside and outside of the base points, control device to be provided, and po-

number of unknown variables must and for other cases involving a dif- sitioning and firing would only occur

not, of course, exceed the total number ferent set of variables, but using the at the chosen coordinates. ■

of equations if the unknown variables same propellant. Edited by Gerald Ondrey

are to be evaluated.

At first, the solution does not ap- Data for the design References

pear feasible since, in some cases, only Performance data used as a design

1. www.handgunsmag.com (Specified data for

five independent defining equations basis for an automated shot blasting Table 2).

are available. As seen in Table 1 and system for coal-fired process heater or 2. www.chuckhawks.com (Specified data for

2, however, a fifth variable, Vm, is usu- boiler are summarized in Table 4. The Table 1)

ally provided in addition to the four calculated data are based on the use 3. Baschung, B., “Inorganic Nanoparticles for

Gun Propellants,” Materials Research Soci-

above. These data are readily avail- of conventional shotgun ammunition, ety Proceedings, www.mrs.org.

able from such sources as hand load- loaded with steel instead of lead shot. 4. Cross, Alan, Coal Fired Process Heaters,

ing books and magazines, and allow Use of steel instead of lead shot is pre- http://www.uspto.gov/patft/.

for full evaluation of all pertinent op- ferred in this application in order to 5. www.chuckhawks.com/shotshell-reloading-

data.html

erating variables, including PBR, Px, avoid potential heating-surface dam- 6. Propellant is 800 –X ; See Ref. [5].

and Ro, as well as the straight line re- age and lead emissions that might 7. Private communication, Barth, Doug (Action

lationship between ln PBR and ln Px. otherwise be carried into the atmo- Automation and Controls, P.O. Box 2540,

10 Larsen Way, North Attleboro, MA 02763;

The value of Px obtained from Fig- sphere by the fluegas effluent. Email: dougb@actionauto.com; URL: www.

ure 1, as a function of PBR, is some- The data for lead shot are based on actionauto.com),

what different than would be predicted field observations using conventional 8. RSI – Pressure Trace, www.shootingsoft-

ware.com/pressure.htm

using the equations derived in this ar- ammunition. The calculation methods

ticle. However, the slope of the original used to determine performance with Author

straight line relationship between ln this ammunition were found to very Alan Cross (73-34 244th

PBR and ln Px, is used in conjunction nearly duplicate the field observed St., Little Neck, NY, 11362;

E-Mail: Across8588@aol.com)

with the equations presented here, the shot pattern size. The same methods is a B.S.Ch.E. graduate from

four data points defined above, and at were therefore used to calculate per- The City College of N.Y. and

an M.S.Ch,E. graduate from

least one additional data point provid- formance data for steel shot, which is the Polytechnic University

ing for a value for Px. With these data required to pass through hot fluegas of N.Y., and has had more

than 30 years of fired heater

and a straight line constructed paral- instead of relatively cool air sur- design experience with ABB

lel to the straight line obtained using roundings. Lummus Heat Transfer (now

CBI Lummus Technology).

the data of Tables 1 and 2, it is pos- Modified conventional semi-auto- Accomplishments include authorship of direct-

fired heater patents and patents pending, relat-

sible to obtain performance data for matic 12-gauge shot guns should be ing to the design of coal fired heaters, and com-

any combination of the four variables used in an automated blasting system pact, low-cost fired heaters capable of processing

low- and high-boiling-point petroleum-based flu-

referred to above. in much the same way as soot-blowers ids, using design strategies that reduce fouling

However, the point-slope calculation are presently used. A major differ- of internal tube surfaces due to coke deposition,

and the design of direct-fired heaters using par-

method should be used only if abso- ence, in the case of the blasting sys- ticulate matter as a heat transfer medium.

48 Chemical Engineering www.che.com July 2009](https://image.slidesharecdn.com/chemicalengineering200907-130204114946-phpapp01/85/Dispersion-Without-Agglomeration-Keep-it-Clean-66-320.jpg)