847-564-9290 Fax: 847-564-9453

be recognized, please consider nominating it for future

Advertising Director: 847-564-9290 Fax: 847-564-9453

© 2009 by Access Intelligence LLC. Federal copyright law prohibits unauthorized reproduction by any means and imposes fines of up to $100,000 for violations.

Chemical Engineering (ISSN 0098-6445) is published monthly by Access Intelligence LLC, 110 William St., 11th Floor, New York, NY 10038. Periodicals postage paid at New York, NY and additional mailing offices. POSTMASTER: Send address changes to Chemical Engineering, Access Intelligence LLC

![Source: Roberts Law Group PLLC

Newsfront

ChemiCal plant

Required if

1) the facility

possesses any of the

chemicals, at the

threshold quantities,

seCurity

listed in Appendix A

or 2) the facility is

DHS directed to do so

by DHS

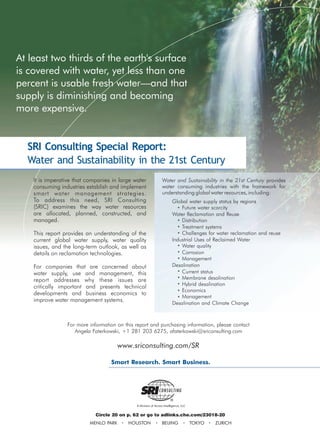

Top screen

Not regulated

Does present a Does not present Monitor

high level of a high level of for material

security risk security risk modifications

Security Final tier Site Security

Regulated Vulnerability determination Plan (SSP)

Assessment (SVA)

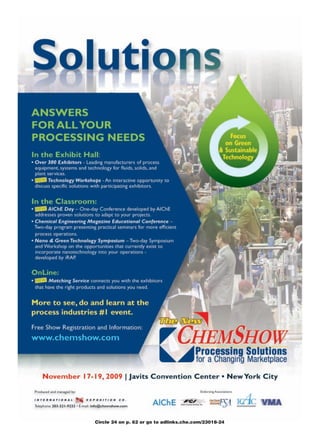

While security has long and SVA review

Material

been a concern for the CPI, modifications?

Compliance and

recordkeeping

DHS reviews the SSP and conducts a

facility inspection. If not approved,

Submit revised

impending changes to CFATS Top screen

deficiencies must be corrected. The

approved SSP is implemented

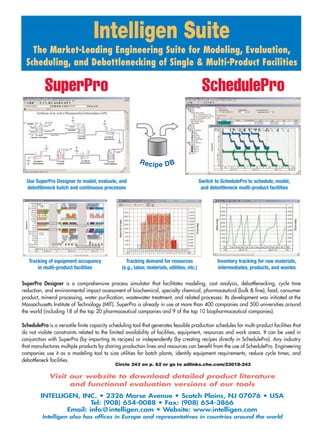

have everyone’s attention Figure 1. The CFATS process is summarized in this flowchart

S

ecurity at many U.S. chemical fa- dix A, which lists approximately 300 plan (SSP) to DHS within 120 days.

cilities is currently regulated by chemicals of interest (COI) and their Roberts says that the first 140 or so

the U.S. Department of Home- individual screening threshold quanti- “final tier letters” were sent out in May

land Security (DHS; Washington, ties (STQ), was published in November 2009, followed by about another 400 in

D.C.; www.dhs.gov) under the Chemi- of the same year. In May 2009, a docu- June. More tier letters are forthcoming.

cal Facility Anti-Terrorism Standard ment entitled Risk-Based Performance Those companies in receipt of the let-

(CFATS). This rule, however, is about Standards Guidance was published. ters are now in the stage of submitting

to expire next month, October 2009. This guide elaborates on the eighteen their SSPs. DHS will review the SSPs

All expectations are that CFATS will risk-based performance standards and determine compliance. However,

be extended for a year, while proposed (RBPSs) that are established in CFATS, “because the regulations are perfor-

modifications to the standard continue and identifies the areas for which a fa- mance-based and risk-driven, what

to be debated in the U.S. Congress. cility’s security will be examined, such ‘compliance’ means can change from

As they work to comply with as perimeter security, access control, facility to facility,” says Roberts. He fur-

CFATS, the chemical process indus- personnel surety (a check on personnel ther explains that denial leads to fur-

tries (CPI) are keeping a watchful eye credentials) and cyber security. ther consultation and “The process of

on the Congressional proceedings that Compliance with CFATS begins with compliance [with CFATS] is continuous

are leading to proposed changes in the an assessment tool developed by DHS as facilities change.” Roberts refers to a

regulation.“CFATS — it is by far the called the Top-Screen, to assist DHS in chart as a quick summary of the overall

most dramatic issue affecting chemi- determining which chemical facilities CFATS compliance process (Figure 1).

cal plant security today,” notes Robert meet the criteria for being high-risk.

Hile, director of integrated security so- Sites possessing chemicals as listed in The big issues

lutions at Siemens Building Technolo- Appendix A at or above the STQs must There doesn’t seem to be any disagree-

gies, Inc. (Buffalo Grove, Ill.; www.usa. submit the Top-Screen questionnaire to ment among the CPI that security

siemens.com/security). DHS for review. As Steve Roberts, an at- regulations are a good idea. In fact the

torney who specializes in CFATS issues Society of Chemical Manufacturers

CFATS in action (Roberts Law Group PLLC; Houston; and Affiliates (SOCMA; Washington

CFATS has come a long way in a short www.chemicalsecurity.com) explains, D.C.; www.socma.com) commends the

time. The approval of the DHS Appro- those facilities deemed high-level risk U.S. Senate for approving legislation

priations Act in October 2006 gave the are then required to submit a security that would extend existing chemical

DHS authority to regulate the security vulnerability assessment (SVA), after security standards for one year. The

of high-risk chemical facilities. CFATS, which a facility is categorized into a American Chemistry Council (ACC;

the implementing regulation, was pub- final risk tier. These facilities must Arlington, Va.; www.americanchemis-

lished in April 2007 and its Appen- then develop and submit a site security try.com) notes that security has long

ChemiCal engineering www.Che.Com September 2009 21](https://image.slidesharecdn.com/chemicalengineering200909-130204120147-phpapp02/85/Membrane-Power-23-320.jpg)

![ADT Advanced Integration

Newsfront

been a priority for its members, who Figure 2. Ground retract-

have invested about $8 billion on fa- able automobile barriers

(GRAB) stop the unauthorized

cility security enhancements under entry of vehicles up to 15,000

ACC’s Responsible Care Security Code. lb, traveling at speeds up to 50

In a recently issued statement, Marty miles per hour

Durbin, ACC’s vice president of Federal

Affairs says, “We believe the ongoing

implementation of the Chemical Fa- it is appropriate for DHS to encourage lowed. Jensen says that the ACC feels

cility Anti-Terrorism Standards dem- the use of IST, but it should be on a vol- adamantly that it is not necessary for

onstrates a smart and aggressive ap- untary basis, possibly with incentives courts to get involved. SOCMA’s All-

proach to both securing and protecting (not necessarily financial) to facilities mond notes that a citizen suit provi-

the economic viability of this essential that implement it. SOCMA’s opposi- sion is common in environmental law,

part of the nation’s infrastructure.” tion to mandatory IST is founded on but it doesn’t even seem feasible in a

There also doesn’t seem to be any dis- several fronts. First, IST within a se- security framework since the details of

sension “on the Hill” about extending curity framework is already addressed a facility’s security plan would not be

CFATS. As she addressed the approxi- by two other well-entrenched regula- accessible to the public because they

mately 350 participants at the 2009 tions: 1) the U.S. Environmental Pro- are deemed CVI (chemical-terrorism

Chemical Sector Security Summit held tection Agency’s (EPA) Risk Manage- vulnerability information), which is

in Baltimore, Md. on June 29 to July 1, ment Program Rule (RMP); and 2) the confidential and known only to DHS

Holly Idelson, majority counsel for the U.S. Occupational Safety and Health and designated facility employees.

Senate Homeland Security and Govern- Admin.’s (OSHA) Process Safety Man- While the IST and civil suits issues

ment Affairs Committee put it this way, agement Regulation. A great concern are the main areas of disagreement

“The debate is what should the program is that a chemical deemed to be a safer between the organizations represent-

be, not should there be a program.” Ms. alternative might be mandated by ing the CPI and the proposed House

Idelson made it clear that as the Senate government officials without a full un- bill, there are other areas of discus-

committee works on defining what the derstanding of the many ramifications sion. These questions include who

program should be, it welcomes input of that chemical substitution. should be covered in CFATS, such

from the CPI to let the members know Allmond uses manufacturers of active as when it comes to water-treatment

what is working and what is not work- pharmaceutical ingredients (APIs) as facilities and industrial versus agri-

ing in CFATS, saying, “Our [the Senate an example of where unexpected com- cultural uses of ammonium nitrate.

Committee’s] door is open.” plications could arise. API manufactur- ACC’s Jensen puts it into perspective,

Since the clock has just about run ers go through a lengthy process of U.S. though, when he says, “We [the CPI,

out for a standalone security bill this Food and Drug Administration (FDA) U.S. Congress and DHS] agree on

year, CFATS is well on its way to a approvals. If, for example, a so-called more than we disagree” including the

one-year extension. It is also expected “safer alternative” compound were overall objective of having permanent

that in this upcoming year discussions mandated, this new compound might Federal chemical security regulations.

about what a permanent rule should require an untenable amount of retest-

look like will intensify. While the U.S. ing before the switch could occur, and it Integrators and suppliers

Senate has not yet formed its own ver- might not be approved by the FDA. As tiered facilities move forward with

sion of a bill, The House of Represen- The ACC also opposes mandatory their site plans, a number of companies

tatives has proposed a revision to the IST. Scott Jensen, director of commu- are positioning themselves to help with

current CFATS standard. The details nications for ACC says that making the process of CFATS compliance and

are where the dissension begins. IST mandatory in a security regula- implementation. Hile says that Siemens

Bill Allmond, vice president of Gov- tion brings “discomfort and concern can help “from start to finish”, offering

ernment Relations and ChemStew- for facility operators since determina- “assistance from the very early stages

ards for SOCMA explains that the two tion is based on one factor, whereas all the way through to the implementa-

main points in the House’s bill that a facility makes that determination tion.” One form of assistance is a sur-

SOCMA opposes are: 1) mandated in- based on many factors.” Jensen states vey package that helps to break down

herently safer technologies (IST); and simply that ACC’s position is that “it CFATS into “layman’s” terms giving a

2) a civil suits clause. is not necessary to include [manda- facility a sort of template to help form

IST encompasses a wide breadth tory] IST” in the security bill because the SVA, and then further down the line

of chemical processing procedures, the current CFATS program allows for to help with the plan (SSP). Siemens is

equipment, protection and the use of and encourages IST implementation. poised to offer an array of surveillance

safer substances. Allmond states that Both SOCMA and the ACC also products and perimeter-intrusion-de-

SOCMA “adamantly opposes manda- oppose the civil suits clause in the tection systems. The majority of RBPSs

tory IST” and more to the point “What House’s proposed legislature, which in CFATS deal with the physical secu-

SOCMA opposes the most is getting would allow any citizen to sue a com- rity of a site, so these types of products

into [mandatory] chemical substitu- pany if their perception is that the are expected to be an important part of

tion.” He explains that SOCMA agrees CFATS regulation is not being fol- a site’s security plan.

22 ChemiCal engineering www.Che.Com September 2009](https://image.slidesharecdn.com/chemicalengineering200909-130204120147-phpapp02/85/Membrane-Power-24-320.jpg)

![Andrew Wray, senior global market- have been around for some time, but at the Dow Chemical Co. puts it, “In se-

ing manager with Honeywell Process never utilized in the private sector curity you have a purposeful, intelligent

Solutions (Phoenix, Ariz.; www.honey- the way they are now,” says Loughin adversary. How do you measure that?”

well.com) says that to achieve increas- as he gives examples of fiber-based Still, Cosman and his colleagues on the

ing levels of security, more and more fence detection, thermal imaging, ISA99 Committee, with contributions

technology needs to be integrated. video analytics and radar. “I believe from other groups, such as ACC’s Chem

Honeywell is well-positioned to offer the day of the six-foot chain-link fence ITC, are making headway in defining

integration with a single system for is over for the highest-risk facilities,” cyber-security standards that will be

control, he adds. Looking ahead, Wray he says, citing that K-rated and high- applicable to a broad industry base. A

says that “as more and more systems security-fencing and barrier technol- concept gaining momentum is the de-

are integrated into the network, more ogy are now being used (Figure 2). velopment of security assurance levels

products need to make decisions ‘at Loughin notes that ADT has Safety (SALs), comparable to SILs. Cosman

the edge’.” To explain what he means (Support Anti-terrorism by Fostering says that the “SAL concept has a lot

by at the edge, Wray gives the example Effective Technologies) Act Certifica- of promise. It is going to get us some-

of a card reader at a facility perimeter. tion for electronic security services. where, I just don’t know how far.”

While the card reader likely has local This DHS-designated certification is John Cusimano, director of se-

decision-making capabilities, new a way to manage the risk of liability, curity solutions for exida (Sellers-

technology is emerging that will check says Roberts, who advises companies ville, Pa.; www.exida.com) explains

the integrity of the reader’s data prior to consider Safety Act protection as a that it has been a long process, but

to gaining access to the network. factor when selecting a security ven- the IT security and control-system

“Integration of multiple technolo- dor during the procurement process. communities have successfully co-

gies is key,” agrees Ryan Loughin, di- operated to develop cyber standards

rector of the Petro-Chem and Energy The cyber side and methodologies, and that “Re-

Div. of ADT Advanced Integration While the bulk of CFATS focuses on cently the safety system community

(Norristown, Pa.; www.adtbusiness. the physical plant, it also addresses has joined this effort, bringing [its]

com/petrochem-ce). He goes on to say cyber security, which is undoubtedly proven risk-mitigation engineering

that “The overall security philoso- an integral part of overall security. methods to the table.” Among other

phy at a plant is changing. Security Part of the issue with regulating cyber services, exida offers a Control Sys-

is now a program much like safety security is how to quantify what level tem Security Assessment to review

has been for years…CFATS is driv- of cyber security one needs, or has. Ex- the cyber-security environment of a

ing this program-related process.” perts are using their experience with facility and compare it with indus-

Loughin explains that a tiered facil- safety standards to focus on this issue. try best practices with recommen-

ity faces two basic threats: toxic re- In the safety arena, metrics can be dations to address possible gaps. As

lease, and theft and diversion. ADT’s assigned according to probability on a momentum increases in the efforts to

approach to working with a facility scale of safety integrity levels (SILs; see standardize cyber security, everyone

with one or both of these threats is CE, Sept. 2007, pp. 69–74). Assigning seems to agree in the prediction that

to consider three key factors: deter, metrics to security, however, poses a big- it will become a more integral part of

detect and delay. “Many of the tech- ger challenge. As Eric Cosman, co-chair future security regulations. ■

nologies being used on these facilities of the ISA99 Committee and who works Dorothy Lozowski

CPI EnErgIzEd consortium headed by the Karlsruhe (Suwon, S. Korea; www.samsungsdi.

(Continued from p. 20) Institute of Technology (Karlsruhe, com) was selected by BMW (Munich;

port construction of a Michigan facil- Germany; www.kit.edu) to develop www.bmw.com) to supply Li-ion batter-

ity to produce battery component ma- novel battery materials that will in- ies for its “Megacity” electric vehicle.

terials, battery cells and battery packs crease energy density in cells intended Even as commercial production of

for HEVs and PHEVs. for electric vehicles. Li-ion batteries draws near, indus-

Private sector players in Europe are trial R&D moves forward on several

European battery activity positioning themselves for the advanced fronts, including exploring new elec-

While the U.S. DOE grant program was battery market as well. Evonik Indus- trode material combinations and

grabbing attention in August, efforts tries AG (Essen, Germany; www.evonik. structures, as well as processing

to develop batteries for HEVs/PHEVs com) and Daimler AG (Stuttgart, Ger- improvements to lower cost and im-

continued elsewhere. In July, the Euro- many; www.daimler.com) established a prove consistency and quality. At the

pean Commission (Brussels, Belgium; development and production partner- same time, academic laboratories are

ec.europa.eu) identified “high-density ship and launched plans to construct further investigating the application

batteries” as a priority in its funding a Li-ion battery plant in Kamenz, Ger- of nanoscale engineering to electrode

to develop HEVs and PHEVs. many. Production will begin in 2011. materials, reaction dynamics on elec-

With €20 million from its own eco- SB LiMotive, a joint venture of Robert trode surfaces, novel electrode mate-

nomic stimulus package, the German Bosch GmbH (Gerlingen, Germany; rials and electrolytes. ■

government is setting up a research www.bosch.com) and Samsung SDI Scott Jenkins

ChemiCal engineering www.Che.Com September 2009 23](https://image.slidesharecdn.com/chemicalengineering200909-130204120147-phpapp02/85/Membrane-Power-25-320.jpg)

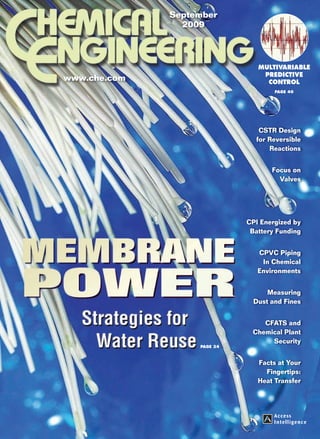

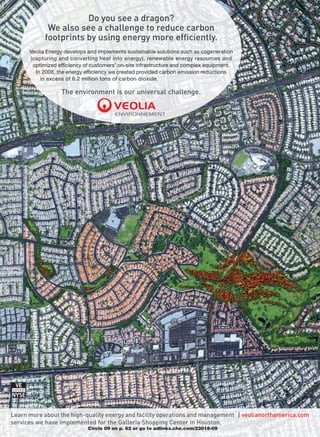

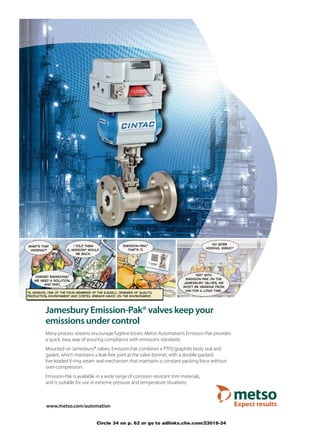

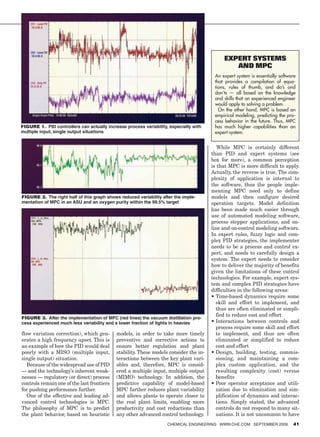

![Table 1.VolumeTric efficiency for equaTion (14a)

Engineering Practice (14a)

X1/Xe Xe 1–(X1/Xe) log[1–(X1/Xe)] (V/VT)Xe V/VT

lent. The volumetric flowrate is the

0.1 0.7 0.9 –0.046 0.948 1.355

same in all cases (a batch operation

for one complete reaction cycle). Thus, 0.2 0.7 0.8 –0.097 0.893 1.275

the ratio of comparison should be V for 0.3 0.7 0.7 –0.155 0.832 1.189

plugflow or batch operation (reaction

0.4 0.7 0.6 –0.222 0.766 1.095

volume and time only) compared to

VT for multiple CSTRs. This ratio (V/ 0.5 0.7 0.5 –0.301 0.693 0.990

VT), volumetric efficiency is expressed 0.6 0.7 0.4 –0.398 0.611 0.873

as Equation (14), and is derived from

0.7 0.7 0.3 –0.523 0.516 0.737

Equations (6b) and (13d).

V 0.8 0.7 0.2 –0.699 0.402 0.575

k C X

v F A0 e 0.9 0.7 0.1 –1.000 0.256 0.366

VT

k C (14) TABLE 1. For any ratio of conversion per stage to equilibrium conversion, this table

v F A0 provides the corresponding volumetric efficiency, based on Equation (14a)

2.303 log 1 X f X e

M 1 The volumetric efficiency is calculated

X1 X e log 1 X f Xe 0 X e2 Xe M

KCB0 as Equation (23).

1 X1 X e log 1 X1 X e (18a) V

Using the quadratic equation, Equa-

VT

tion (18a) becomes (18b). (23)

V 2.303 log 1 X1 X e 2.303 1 X 1 X e

(14a)

2 log 1 X1 X e

M 1 M 1 Xe X 1 Xe

VT X e X1 X e 4M

KCB0 KCB0

log 1 X1 X e Xe (18b)

2 Reversible production of a

dimer from twin reactants

Volumetric efficiency is independent Using Equations (17) and (18a), an ex-

In another alternate but similar case,

of the initial or final concentration pression for Xf is found.

Equation (15) is modified for double

and velocity constant at constant tem-

M 1 components that are reversibly re-

perature, as well as overall conver- r kF CB0 X f2

2

Xf M

KCB0 acted to form a dimer, as shown in the

sion. It is dependent on only the ratio (19a)

reaction below. As in this last case,

of the first stage conversion compared Equation (19a) can be simplified to

there is only one product.

to the equilibrium conversion. Calcu- Equation (19b) using the quadratic

lations for Equation (14a) are shown equation. 2A P

in Table 1. 2 −r = kF C A 0 2 − kR CP

M 1 M 1 (24)

4M

Reversible production of a KCB0 KCB0 (19b) CPf = C A 0 X f

dimer from two reactants Xf (25)

Another case exists, where two com- 2 2

ponents are reversibly reacted to form r kF C A 0 2 1 Xf kF K C A 0 X f

a single product, a dimer, rather than 2

r kF CB0 X e 1 X f Xe (19c) (26a)

two products (as shown in the reaction 2 2

below). This case is similar to the pre- r kF C A 0 Xf 2 KC A 0 X f 1

V1 kF CB0 X e

vious case, but but with only one prod- ln 1 X1 X e (20a) (26b)

uct, as shown below in Equation (15). v

At equilibrium, the rate is zero.

The volume of each backmixed stage

C D P is equal. 0 X e2 2 KC A 0 X e 1

(27a)

r kF CB CD kR C p Using the quadratic equation, Equa-

(15) V1 kF CB0 X e X1 X e tion (27a) becomes (27b).

v 1 X1 X e (20b)

CB0 X f CB0 CBf C pf

(16a) X e 1 KC A 0 1 KC A 0

2

1

CB1 CBe (27b)

C pf CB0 X f 1 X1 X e

(16b) (21)

CB0 CBe Xf 1 KC A 0 1 KC A 0

2

1

Xf (28a)

CBn CBe

r kF CB20 1 Xf M Xf 1 X f Xe r kF C A 0 12

X f Xe

KCB0 CB0 CBe (28b)

n

(17) 1 X1 X e (22) For a plugflow reactor, the following

At equilibrium, the rate is zero. expression is true.

48 ChemiCal engineering www.Che.Com september 2009](https://image.slidesharecdn.com/chemicalengineering200909-130204120147-phpapp02/85/Membrane-Power-60-320.jpg)

![Summary of equatioNS Subscripts

[6] NomeNclature 0 Initial conditions

B D P S

1,2,3 First, second and third stages

2

M 1 M 1 4M 1 K K C Concentration, A For component A

Xe moles/unit volume

C For component C

2 K 1 K k Reaction rate

constant D For component D

2

K Equilibrium constant e Equilibrium conditions

M 1 M 1 4M 1 K K

Xf M Initial mole ratio of D/B f Overall or final conditions

2 K 1 K n Number of stages F Conditions for forward reaction

2A G H G For component G

r Reaction rate

1 1 1 K t Reaction time H For component H

Xe V Reactor volume j Any stage in the series of reactor stages

K 1 K n The nth stage

v Volumetric flowrate

X Conversion P For component P

1 1 1 K

Xf R Conditions for reverse reaction

K 1 K T The total of all n stages

C D P

2 References Author

M 1 M 1 Ralph Levine is a retired

4M 1. Levenspiel, O., “Chemical Reaction Engi- chemical engineer currently

KCB0 KCB0 neering,” John Wiley Sons, Inc., 1962. working as a consultant

Xe 2. Levine, R., Hydro. Proc., July 1967, pp. for plants, design or opera-

2 158–160. tions and RD (578 Arbor

2 Meadow Dr., Ballwin, Mo.

M 1 M 1 3. Levine, R. A New Design Approach for 63021; Email: ralphle2000@

4M Backmixed Reactors — Part I, Chem. yahoo.com). Levine earned a

KCB0 KCB0 Eng. July 1, 1968, pp. 62–67. B.S.Ch.E. from the City Uni-

Xf 4. Levine, R. A New Design Approach for versity of New York, and did

2 Backmixed Reactors — Part II, Chem. graduate work at Louisiana

Eng. July 29, 1968, pp. 145–150. State University and the Uni-

2A P versity of Delaware. Levine later served as an

2 5. Levine, R. A New Design Approach for engineer for the U.S. Army Chemical Corps. He

X e 1 KC A 0 1 KC A 0 1 Backmixed Reactors — Part III, Chem. has worked for DuPont, Cities Service Co., and

Eng. Aug 12, 1968, pp. 167–171. most recently, Columbian Chemical Co. Levine

2 6. Levine, R. CSTRs: Bound for Maximum has filed several U.S. patents during his career,

Xf 1 KC A 0 1 KC A 0 1 Conversion, Chem. Eng. Jan. 2009, pp. and is a published author, with his work fea-

30–34. tured in Chemical Engineering and Hydrocar-

CPD-5 8/20/07 10:34 AM Page 1 bon Processing.

V C A 0 kF X e

ln 1 X f Xe (29)

v

The expression for multiple CSTRs is

given as Equation (30). The best way to heat and cool

V1 C A 0 kF X1 X e (30) the most corrosive materials.

v 1 X 1 Xe

n

1 X1 X e 1 X f Xe

C An C Ae (31)

C A0 C Ae

Nothing controls

The volumetric efficiency is found to temperatures of

be Equation (32). corrosives and high

purity materials better

V 2.303 1 X1 X e than AMETEK fluoropoly-

(32)

VT Xe X1 X e mer heat exchangers. Not

glass. Not silicon carbide

log 1 X1 X e

or graphite units. Available

The last two cases presented here are with steel or non-metallic

reversible and have only one product. shells, diameters from 3

The differences between these cases to 14 and metric designs,

are the values calculated based on AMETEK heat exchangers

the quadratic equation for both Xe include TEMA/ANSI nozzle and

and Xf. All second order reactions that end connections. To learn more

are reversible and produce one or two call (302) 456-4431 or visit:

products require the quadratic equa- www.ametekfpp.com

tion for the calculation of Xe and Xf for

each case. A summary of these equa-

tions is presented in the box above. ■

Edited by Kate Torzewski

Circle 27 on p. 62 or go to adlinks.che.com/23018-27

ChemiCal engineering www.Che.Com september 2009 49](https://image.slidesharecdn.com/chemicalengineering200909-130204120147-phpapp02/85/Membrane-Power-61-320.jpg)