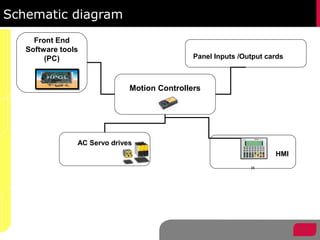

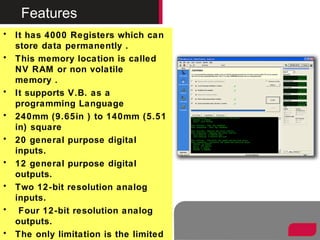

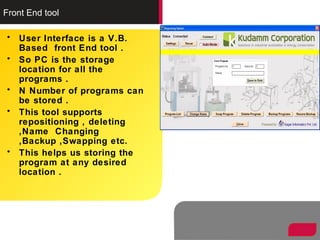

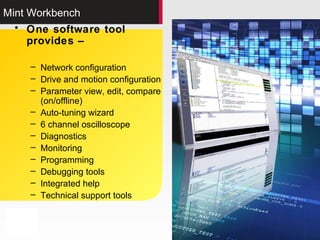

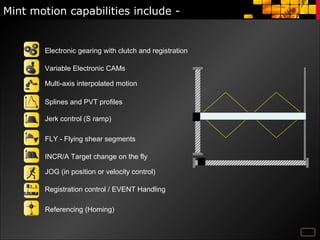

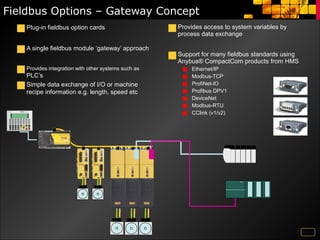

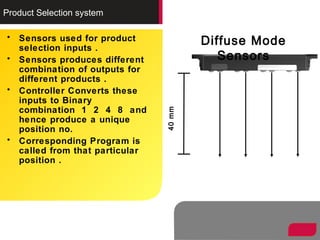

This document describes a dispensing system that uses a Baldor motion controller. It provides details on the controller's features such as memory, programming language support, I/O capabilities. It also describes the user interface software, programming tools, motion control capabilities, fieldbus options and how the system can be used for product selection applications using sensors.