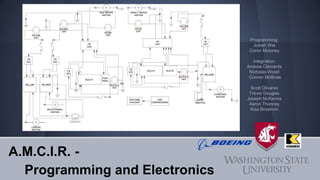

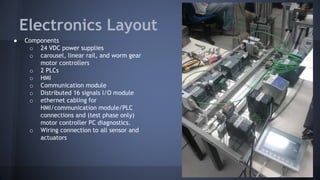

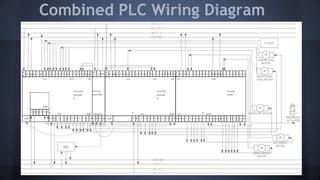

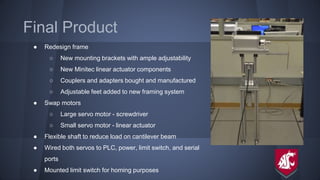

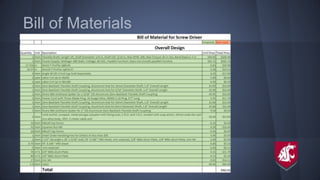

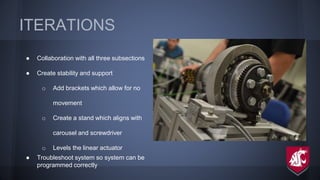

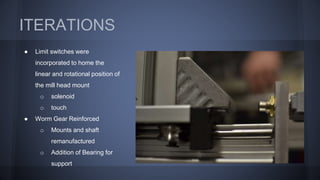

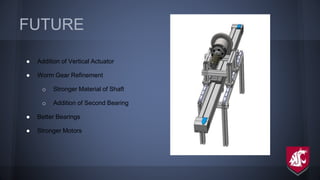

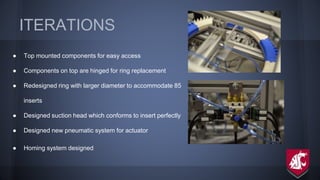

The document describes the design of an automatic mill cutter insert replacement system comprised of three subsystems: a linear actuator, carousel, and screwdriver. It outlines the objectives, previous work, iterations, and final products for each subsystem. The overall system aims to automate the removal and replacement of 85 cutting inserts used to cut titanium. Key achievements include programming the subsystems to work independently and together, redesigning components for improved functionality, and overhauling the electronics and wiring. Future work focuses on increasing mechanical precision and reliability.