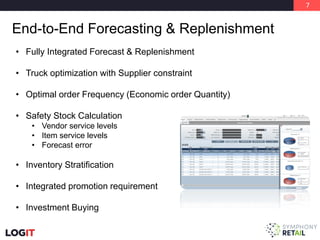

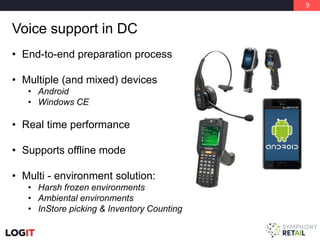

This document summarizes key technologies and trends in warehouse and logistics management. It discusses how warehouse management systems and mobility solutions can optimize warehouse operations, increase efficiency, and reduce costs. It also outlines several emerging technologies like robots, autonomous vehicles, augmented reality, vision picking, and drones that aim to further automate processes and improve productivity in warehouses.