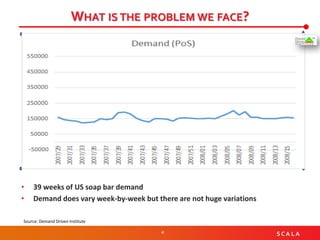

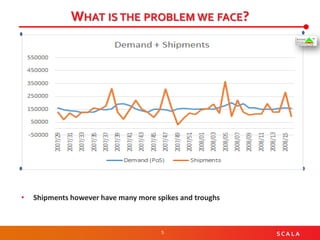

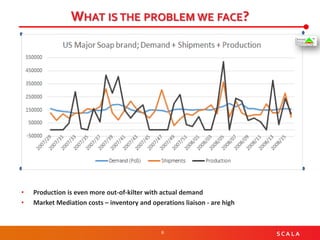

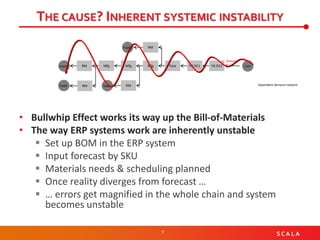

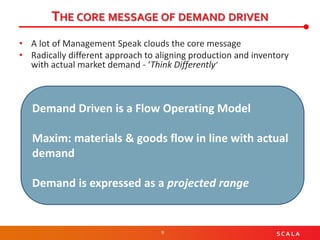

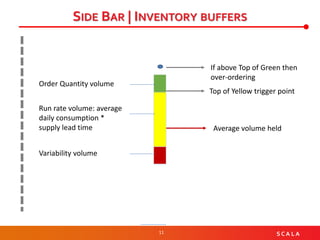

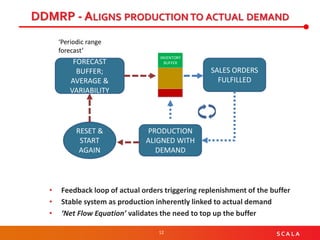

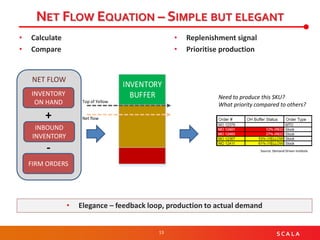

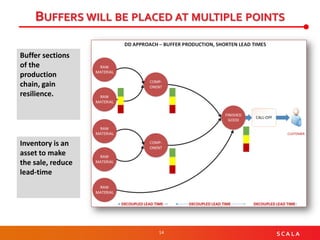

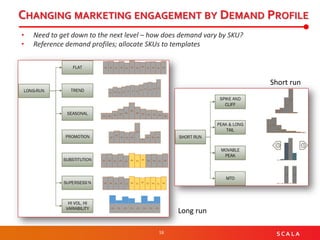

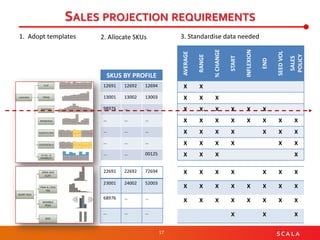

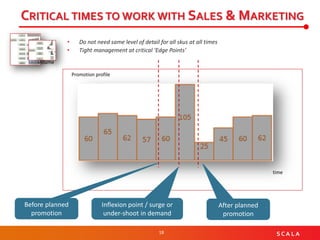

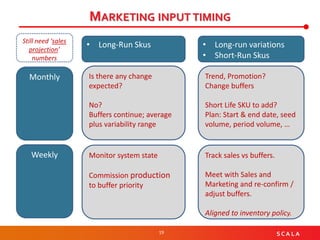

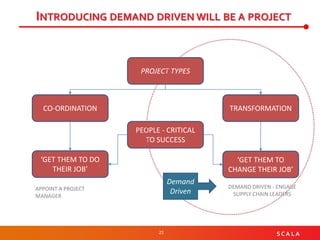

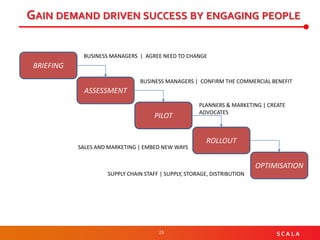

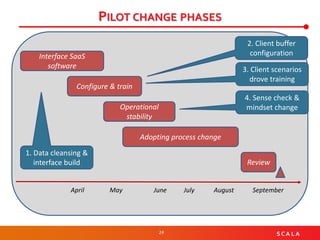

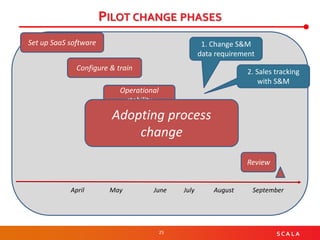

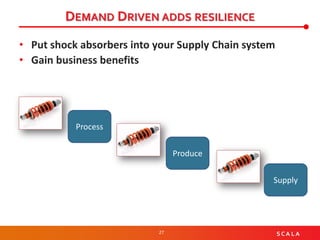

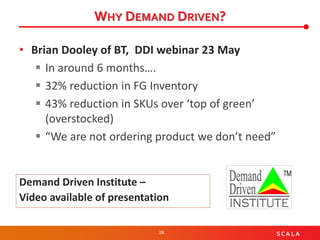

Demand driven principles can help companies better align production and inventory levels with actual market demand. This improves customer service while reducing inventory levels typically by 30%. The presentation discusses how the bullwhip effect and inherent instability in ERP systems can cause shipments and production to vary more than actual demand. Adopting demand driven practices like using inventory buffers and replenishing based on real orders rather than forecasts can create a more stable system. The presentation also covers engaging sales and marketing to provide better demand projections and adjusting processes and roles to successfully implement demand driven strategies.