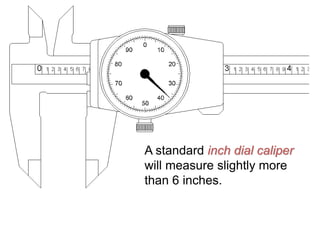

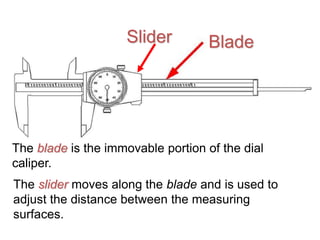

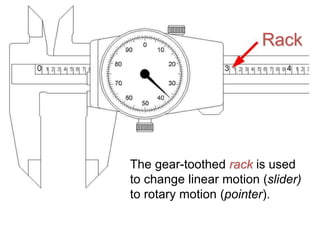

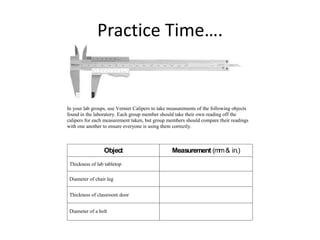

Dial calipers are a common and versatile precision measuring tool. They are used to measure four things: outside diameter or object thickness, inside diameter or space width, step distance, and hole depth. The key parts of dial calipers are the blade, slider, pointer, reference edge, and rack. To take a measurement, you identify the number of inches on the blade scale and reference edge, then add the number of increments after the inch mark and the reading on the dial, which measures thousandths of an inch. Practice using calipers is important to learn how to correctly read measurements.