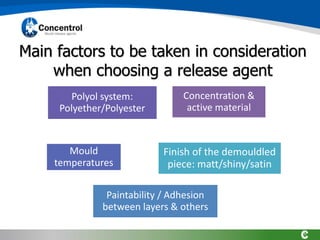

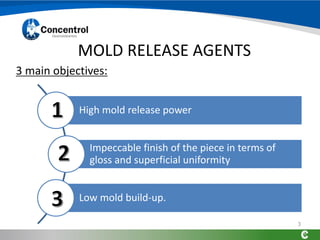

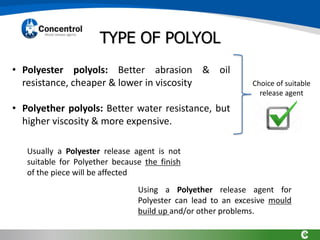

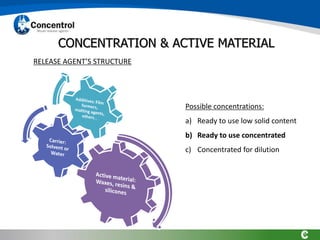

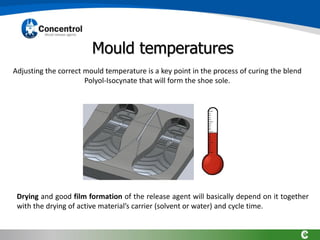

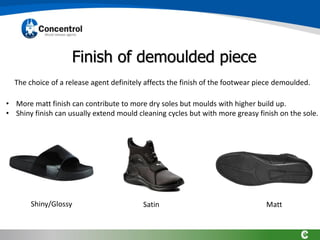

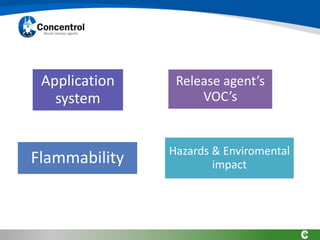

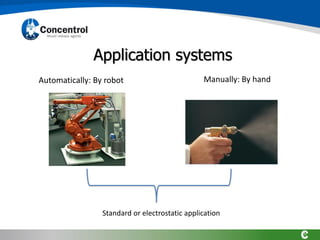

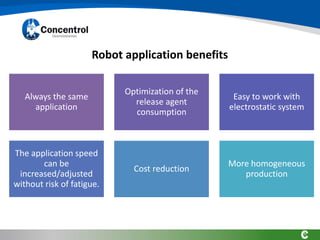

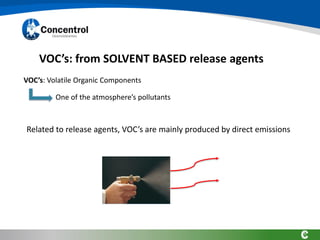

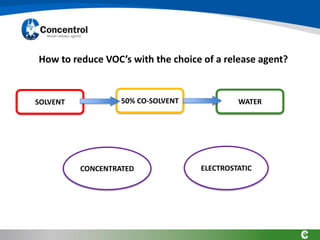

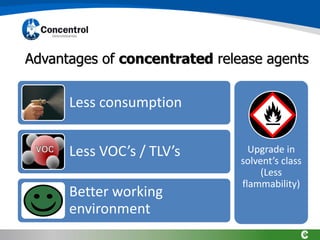

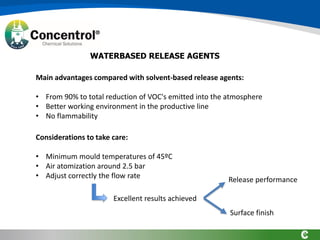

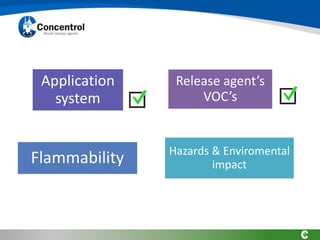

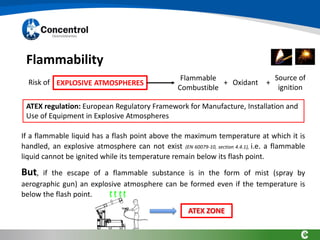

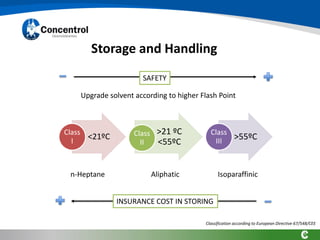

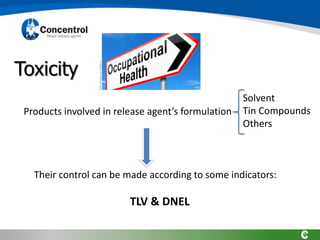

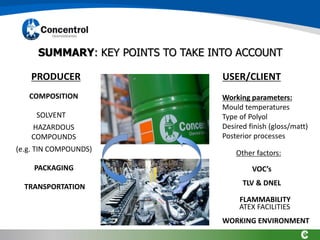

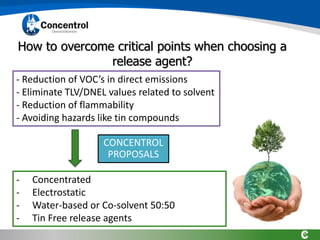

This document discusses key factors to consider when choosing a footwear release agent. It describes the main objectives of release agents as providing high mold release, an impeccable finish on demoulded pieces, and low mold build-up. The type of polyol in the sole material and desired surface finish affect the suitable release agent. Water-based or co-solvent agents can reduce VOC emissions compared to solvent-based options. Application method, concentration level, and ensuring the agent does not interfere with secondary processes like gluing are also important considerations. The document provides an overview of Concentrol, a manufacturer of release agents and other chemicals.