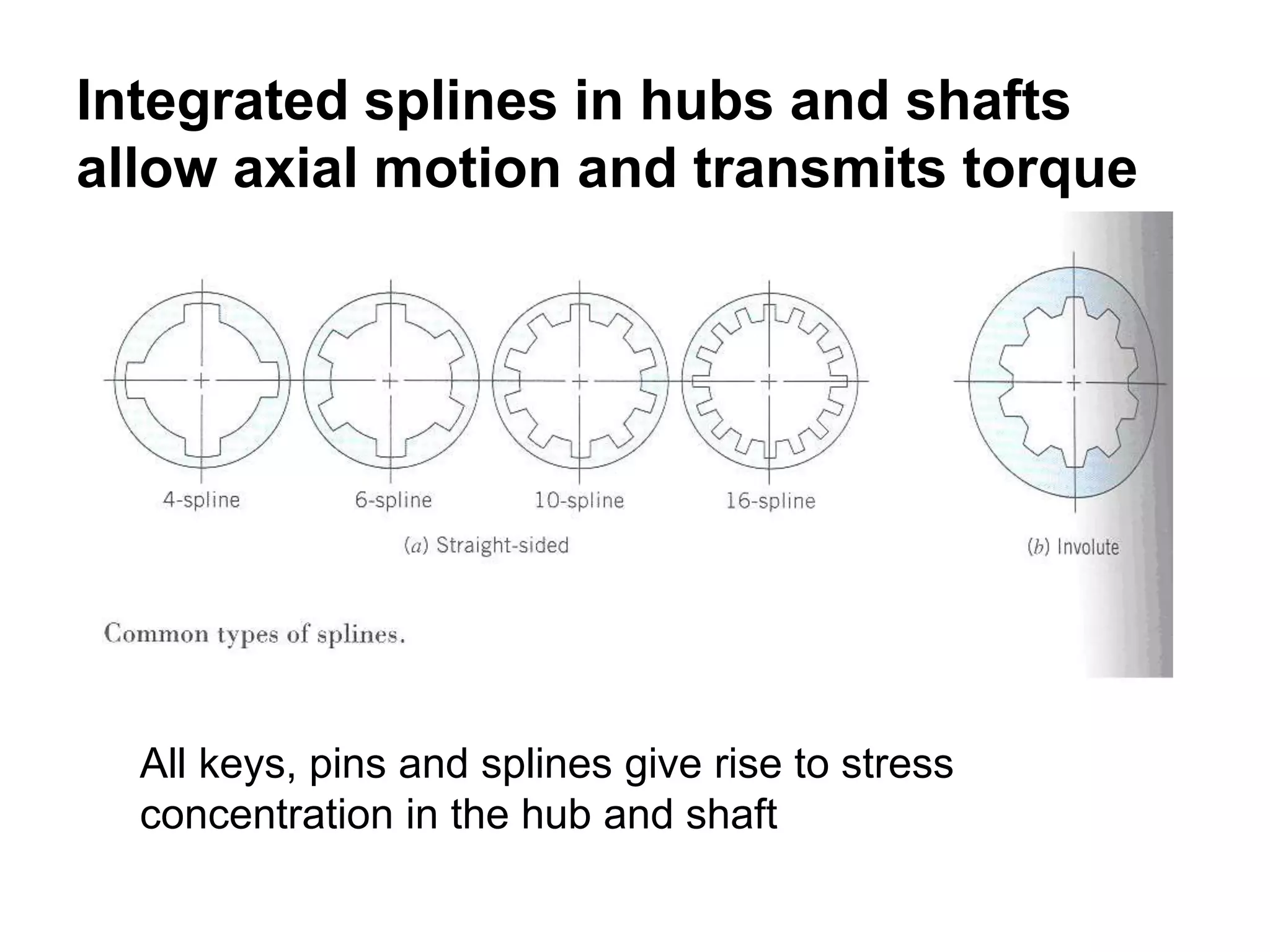

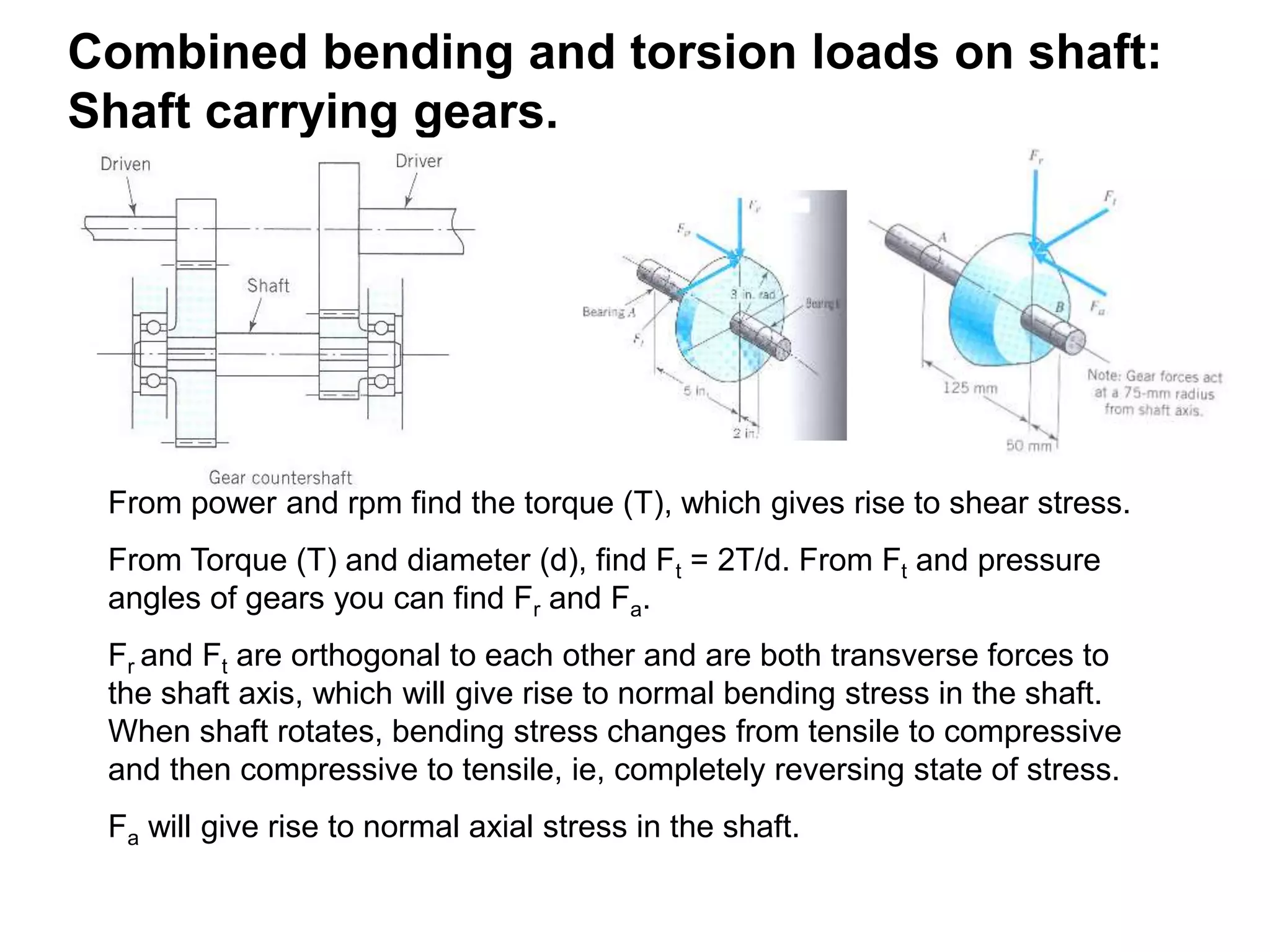

A shaft transmits power and rotational motion. Machine elements like gears and pulleys are mounted on the shaft to transmit power from a motor or engine through a machine. Press fits, keys, dowels, and splines attach these elements to the shaft. The shaft rotates on bearings and uses retaining rings, thrust bearings, grooves, and steps to take up axial loads. Couplings transmit power between drive and driven shafts. Shafts experience torque, bending moments, and combined stresses that must be considered in design based on strength and fatigue criteria to prevent failure.

![Power, toque & speed

For linear motion:

Power = F.v (force x velocity)

For rotational motion

Power P = Torque x angular velocity

= T (in-lb).w (rad/sec) in-lb/sec

= T.(2 p n/60) in-lb/sec [n=rpm]

= T.(2 p n/(60*12*550)) HP [HP=550 ft-

lb/sec]

= T.n/63,025 HP

or, T= 63,025HP/n (in-lb), where n = rpm

Similarly, T= 9,550,000kW/n (N-mm), where n = rpm](https://image.slidesharecdn.com/designofshaft-230425070755-035f2357/75/Design-of-Shaft-ppt-6-2048.jpg)