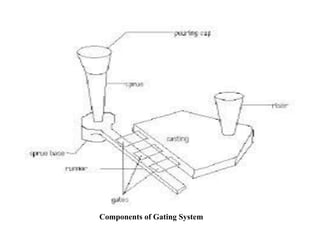

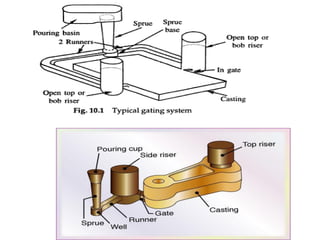

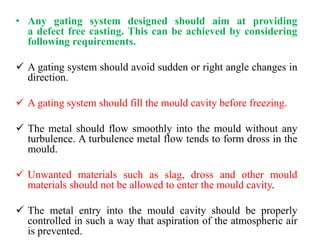

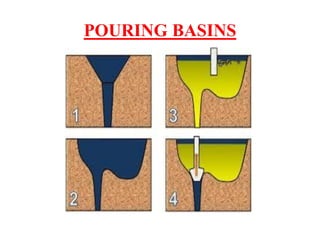

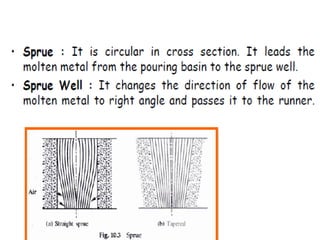

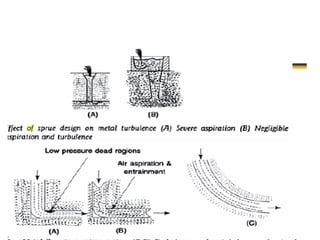

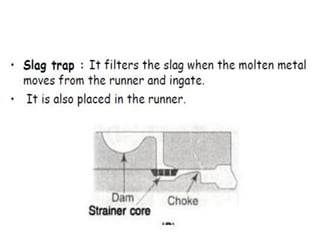

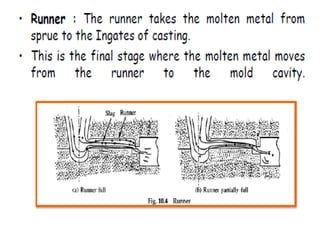

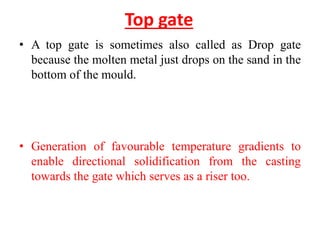

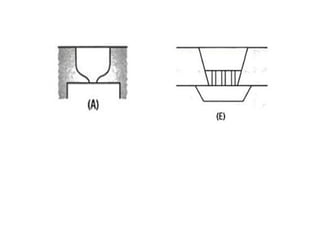

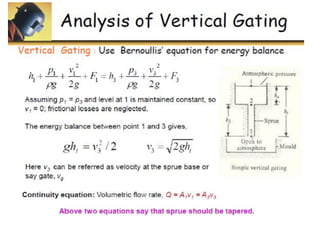

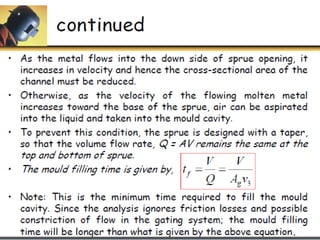

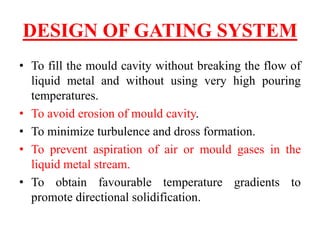

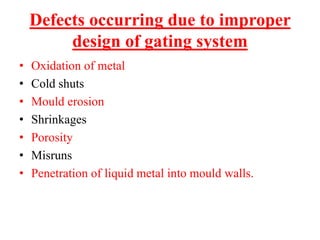

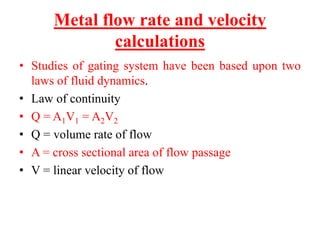

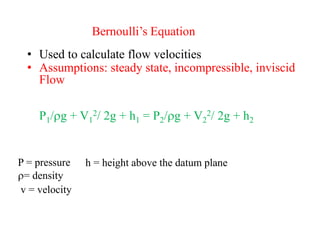

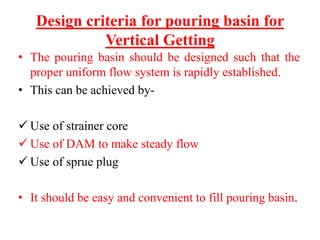

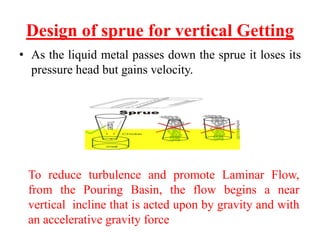

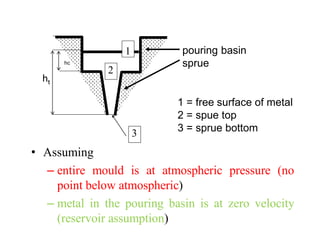

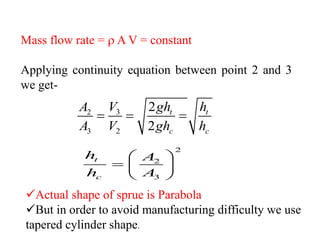

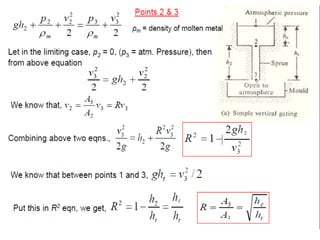

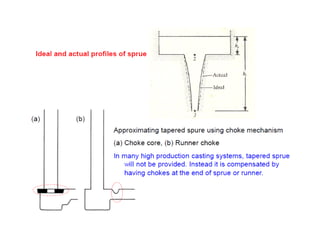

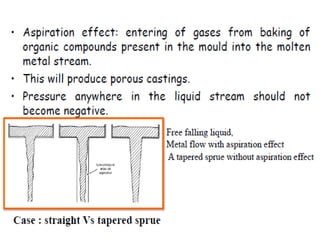

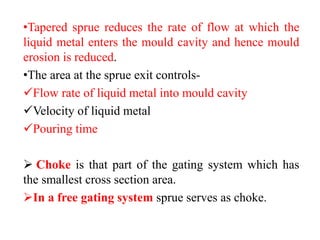

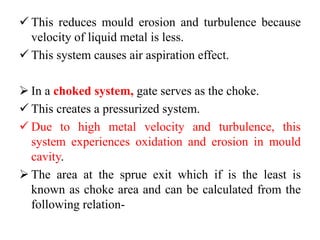

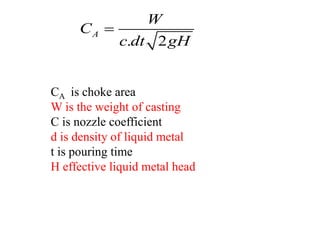

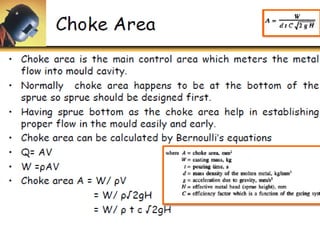

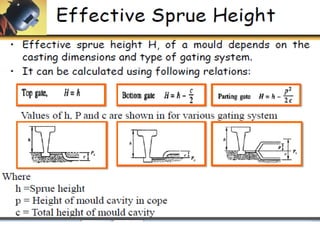

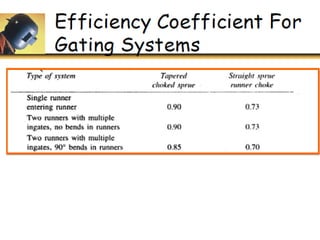

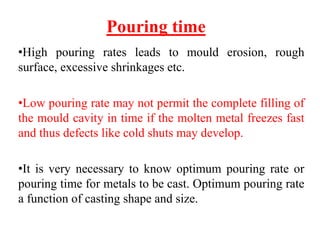

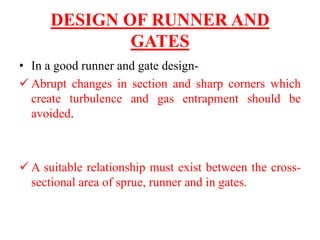

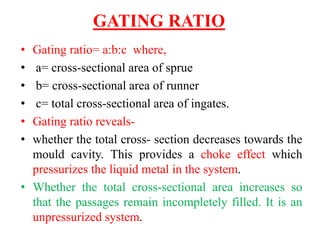

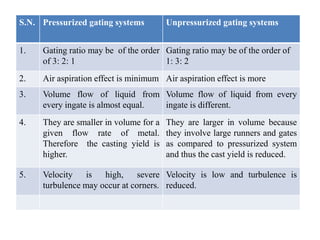

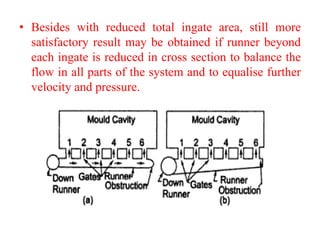

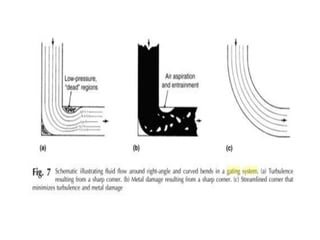

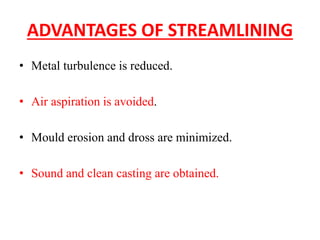

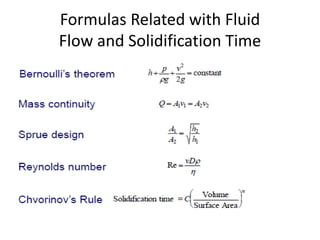

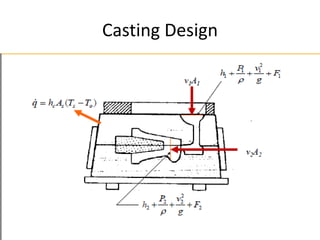

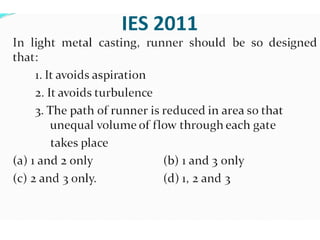

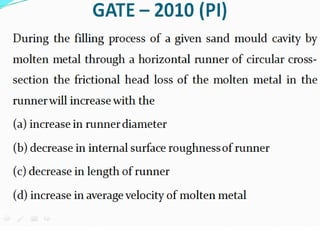

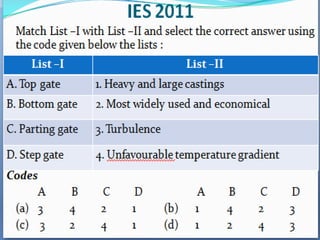

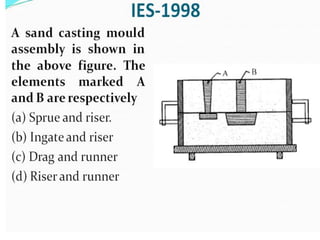

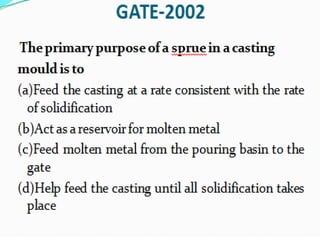

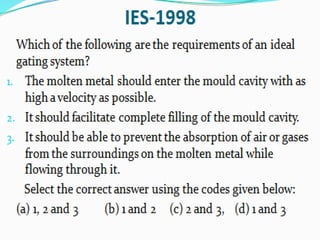

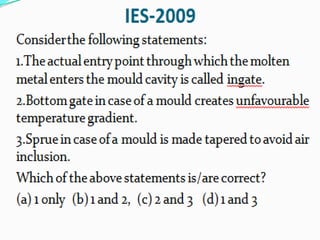

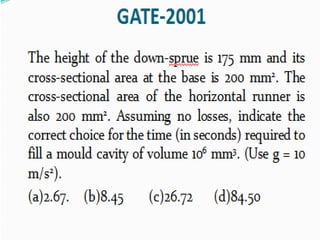

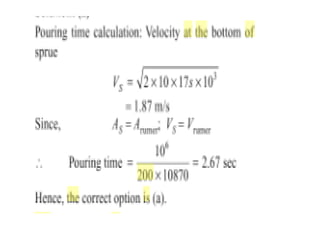

This document discusses the key elements of a gating system for metal casting, including the pouring basin, sprue, runner, and gates. It describes the components and their purposes to provide smooth, controlled filling of the mould cavity. An optimal gating system avoids turbulence, prevents impurities from entering the mould, and maintains proper thermal gradients. The document also covers factors like pouring rate and choke area that influence metal flow, and recommends tapered shapes and gradual transitions to minimize defects.

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-118-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-119-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-120-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-121-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-122-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-123-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-124-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-125-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-126-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-127-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-128-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-129-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-130-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-131-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-132-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-133-320.jpg)

![SY Lectures Gating designe, Raisers Problems[1].pdf](https://image.slidesharecdn.com/sylecturesgatingdesigneraisersproblems1-240402183803-58d6d3a8/85/SY-Lectures-Gating-designe-Raisers-Problems-1-pdf-134-320.jpg)