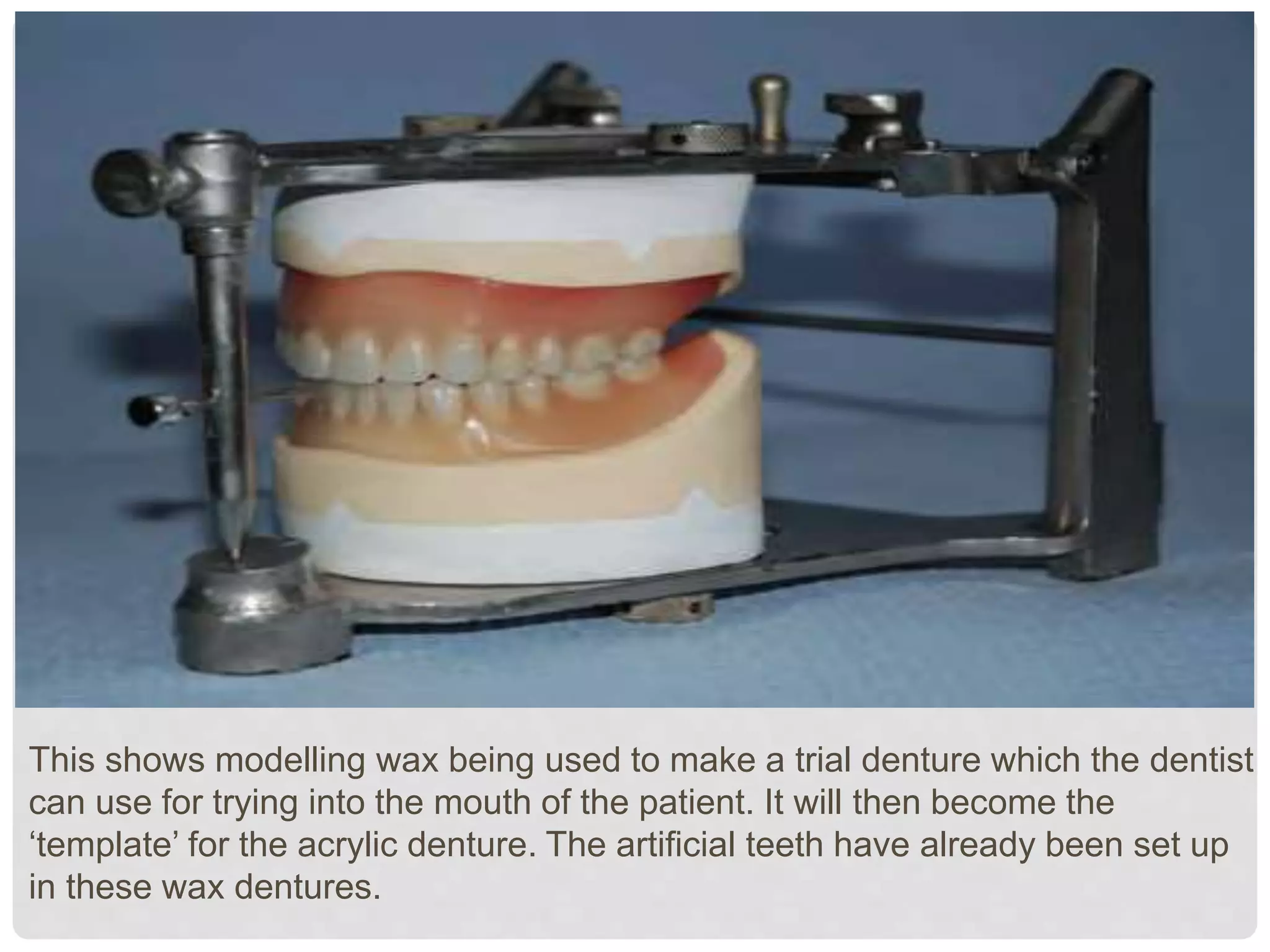

This document discusses dental waxes, including their composition, properties, uses, advantages, and disadvantages. Dental waxes are mixtures of natural and synthetic materials that are soft and mouldable at elevated temperatures but harden at room temperature. They are used to form patterns for dental appliances and restorations. Key properties include melting point, flow value, and thermal conductivity. Common uses are impression wax, modelling wax for dentures, and inlay wax for dental restorations. Advantages are easy manipulation and removal without residue. Disadvantages include poor thermal properties leading to dimensional errors.