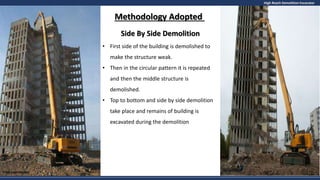

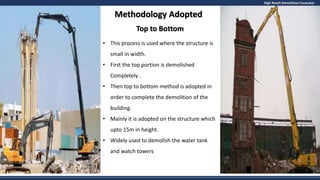

The document discusses high reach demolition excavators as a method for building demolition. It provides details on the specifications and attachments of high reach excavators, which can reach heights up to 57 meters. The document outlines the methodology of side by side and top to bottom demolition techniques used with high reach excavators. It also presents case studies and advantages of high reach excavators over other demolition methods like explosives or wrecking balls, noting they allow for controlled, efficient demolition with less risk.