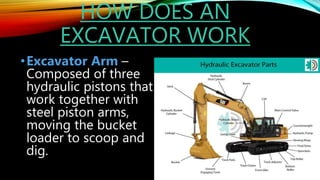

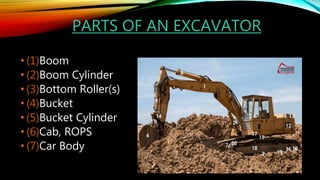

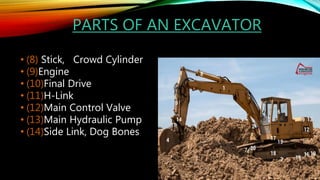

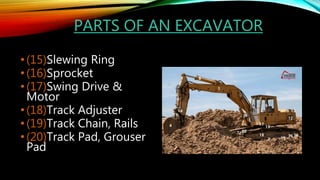

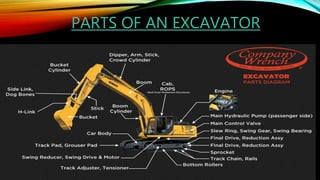

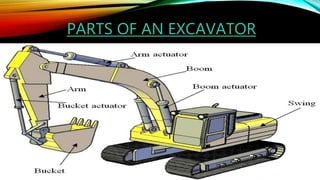

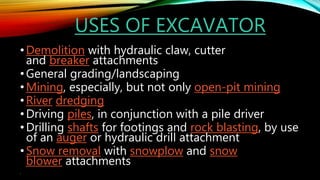

An excavator is a heavy construction machine that uses a bucket and boom to excavate soil and materials. It has a cab for the operator, tracks or wheels for mobility, and a hydraulic arm with attachments to dig and lift. Excavators come in different types for various jobs, including crawler, backhoe, suction, dragline, and wheel excavators. They are used widely in construction, mining, demolition, landscaping, and other industries for digging trenches, loading trucks, handling materials, and more.