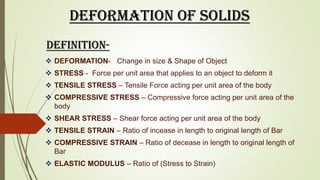

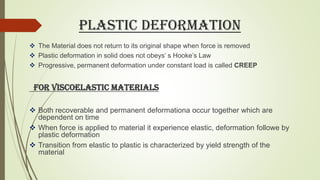

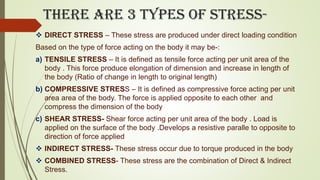

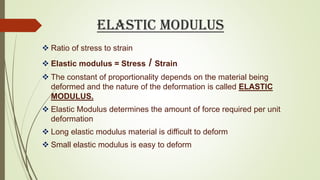

The document discusses the deformation of solids, including definitions of stress, strain, and the processes of elastic and plastic deformation. It describes various types of stress (tensile, compressive, and shear) as well as the concept of creep in viscoelastic materials. The document also highlights the relationship between stress and strain through the elastic modulus and the conditions under which these deformations occur.