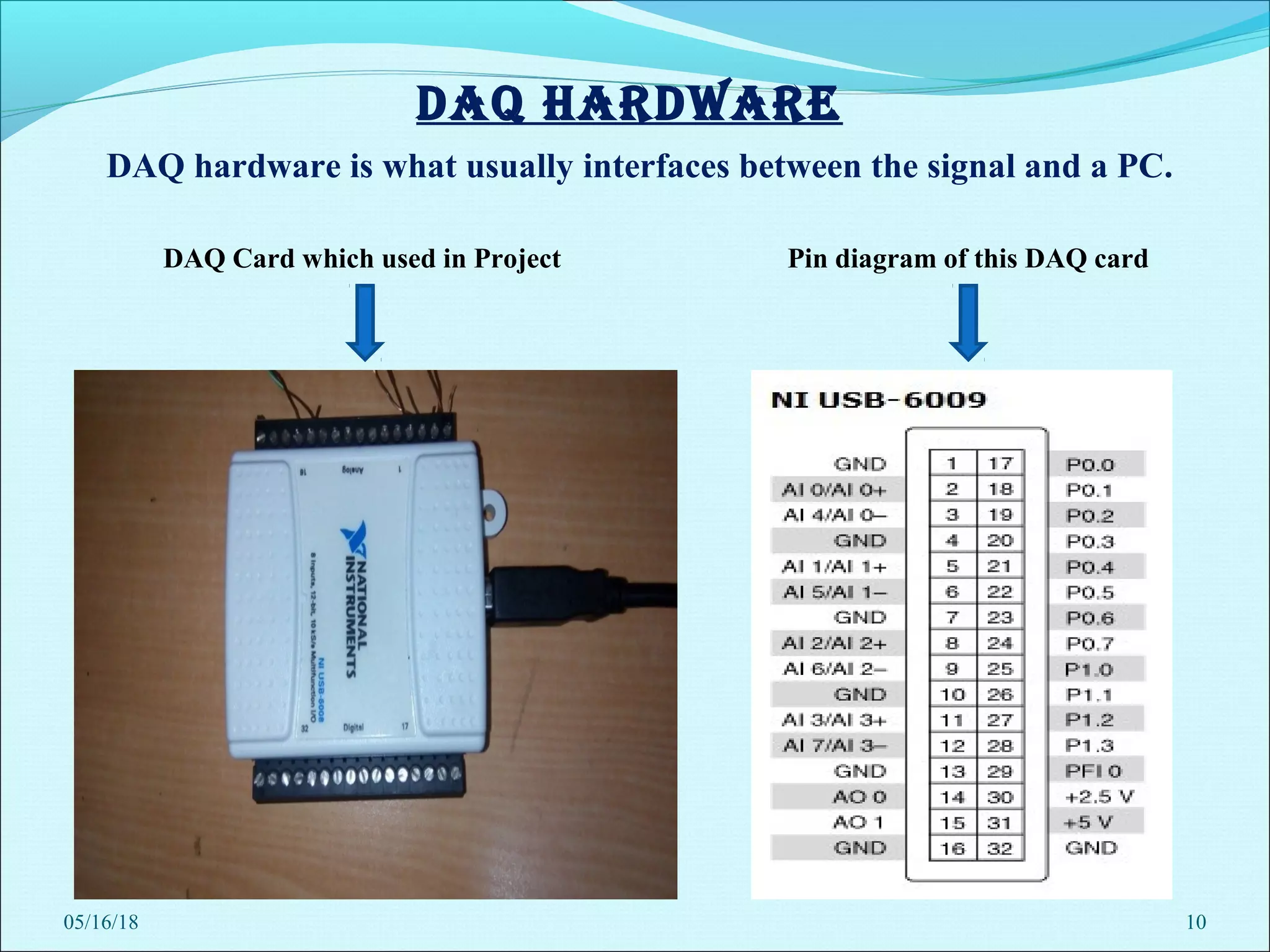

The project focuses on developing a networked data acquisition system for the Indian black tea manufacturing process, aiming to enhance quality and productivity through the use of various sensors and advanced instrumentation. Key objectives include designing signal conditioning circuits, data collection from sensors, and implementing a centralized server setup for real-time monitoring. The results indicate that the system can create a reliable data bank to support future improvements in tea quality and productivity.