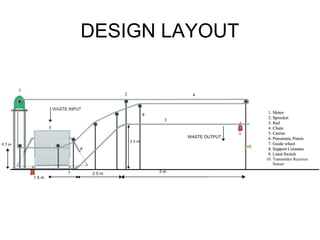

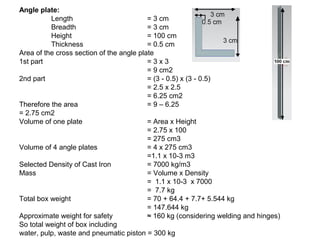

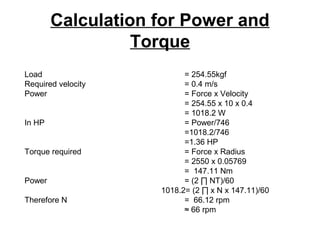

This document provides a design proposal for an Automated Wasted Disposal System (AWDS) for Hindustan Newsprint Limited. The system aims to automate the manual transport of waste from a hopper to a truck. Key elements include:

- A box that collects waste from the hopper and transports it along rails using a chain and sprocket drive powered by a motor.

- Sensors to detect when the box is full and in position by the truck to trigger a pneumatic piston to open the bottom door and release the waste.

- Calculations to design the box, select appropriate chains, sprockets, motors and bearings to support the estimated 300kg load and 0.4m/

![Bearing Design

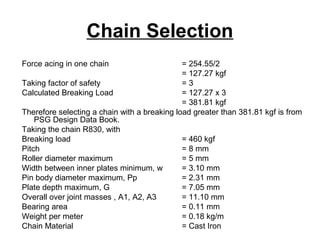

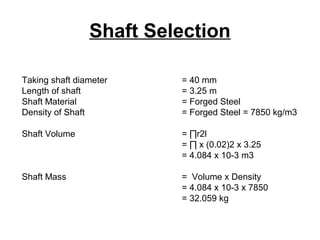

Density of Sprocket = Stainless Steel = 7480-8000 kg/m3

Selecting Density of Stainless Steel = 7500 kg/m3

Sprocket Volume = ∏r2l

= ∏ x ([118.6/2]2 – [40/2]2) x 2.8

= 27414.0778 mm3

Sprocket Mass = Volume x Density

= 27414.0778 x 10-9 x 7500

= 0.205 kg x 2

= 0.411 kg

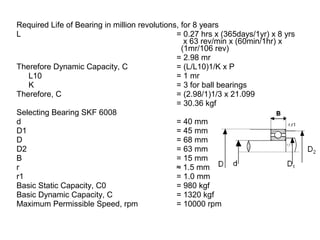

Total Radial Load Acting on the Bearing = Shaft Mass + Bearing Mass

= 32.059 + 0.411

= 32.4702 kg

Axial Load, Fa = 0 kgf

Radial Load, Fr = 32.4702 /2

= 16.23 kg (for one bearing)

Equivalent Load , P = ( X Fr + Y Fa) S

Taking ,

Radial Factor, X = 1

Thrust Factor, Y = 0

Service Factor, S = 1.3

Therefore ,P = X Fr S

= 1 x 16.23 x 1.3

= 21.099 kg](https://image.slidesharecdn.com/15be3b1e-90fe-4436-b786-a59608d787e1-150812234516-lva1-app6891/85/PROJECT-DEMO-final-37-320.jpg)

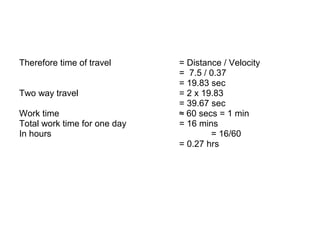

![Length of Chain at Inclination

According to Pythagoras Theorem

AC2 = √( AB2 +BC2)

AC = (2.52 + 2.52)

AC = 3.5 m

Total travel distance = 2.5 +3.5 + 1.5

= 7.5 m

Velocity, V = ω r

Radial Velocity, ω = [(2 x ∏ x N)/60]

rpm, N = 63 rpm

Therefore, V = [(2 x ∏ x N)/60] x r

= [(2 x ∏ x 63)/ 60] x (0.11469/2)

= 0.37 m/s](https://image.slidesharecdn.com/15be3b1e-90fe-4436-b786-a59608d787e1-150812234516-lva1-app6891/85/PROJECT-DEMO-final-38-320.jpg)

![Bearing Probability of Survival

We know that, C1 = (L101/L10)1/K x P1

= (L101/1)1/3 x 21.099

Therefore, L101 = 244870.336 mr

L/L101 = [ln(1/p1)/ln(1/p10)]1/b

L101 = calculated life of the selected bearing, for given load for 90%

survival

Ln(1/p10) = ln(1/0.9) = 0.1053

b = 1.34 for deep grove ball bearings

2.98/244870.336 = [ln (1/p)/ 0.1053)1/1.34

Therefore, p1 = 0.9999

= 99.99%](https://image.slidesharecdn.com/15be3b1e-90fe-4436-b786-a59608d787e1-150812234516-lva1-app6891/85/PROJECT-DEMO-final-41-320.jpg)