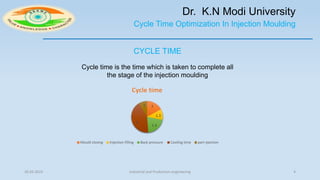

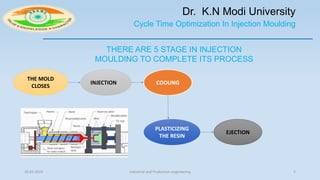

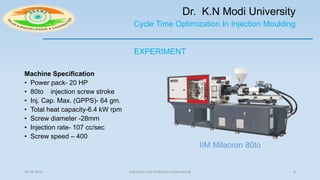

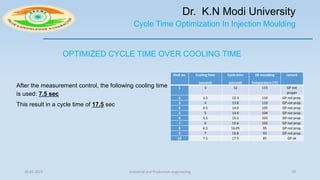

The document discusses cycle time optimization in injection molding, specifically using the Milacron 80to machine to produce card holders. It identifies key factors affecting cycle time, such as cooling time, and presents experimental data that shows an optimized cycle time of 17.5 seconds. The analysis indicates that cooling time significantly impacts overall cycle time, comprising about 50% of the total.